Dust removal device for downhole drill machine for coal mine exploitation

A technology of down-the-hole drilling rig and dust removal device, which is applied in the direction of construction, etc., which can solve the problems of affecting environmental quality, inability to fully absorb dust, and limited dust collection range of dust collection equipment, so as to improve dust removal efficiency, dust removal effect is obvious, and speed up the contact speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

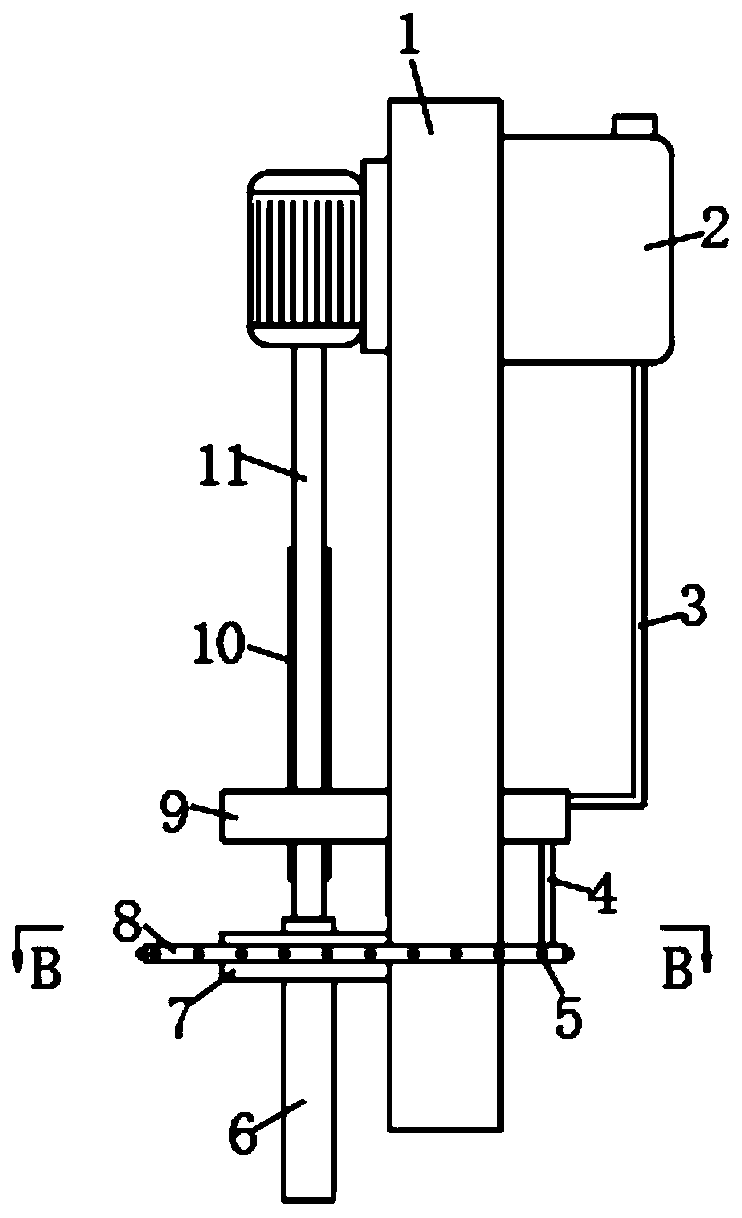

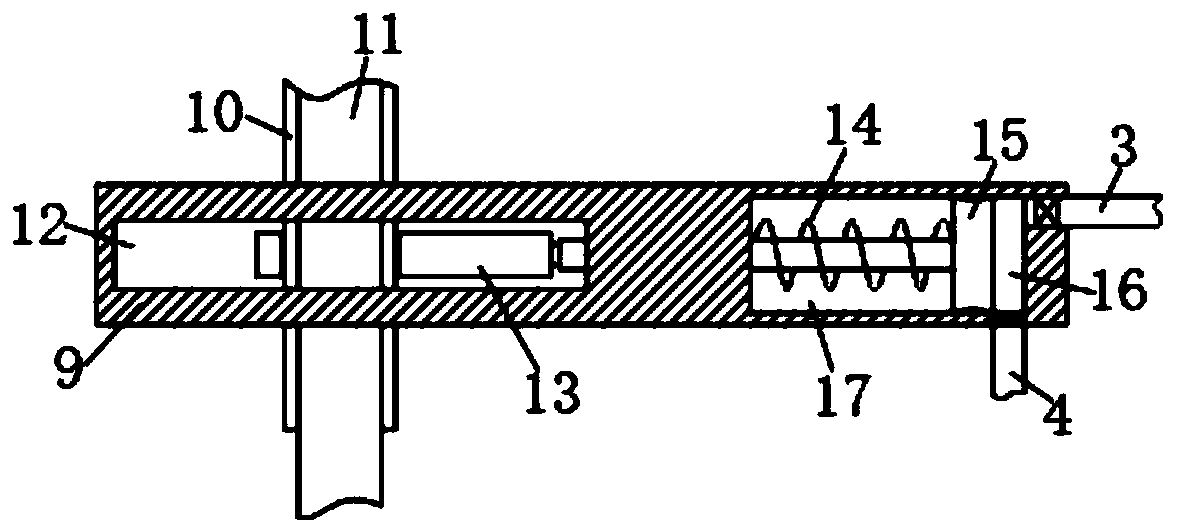

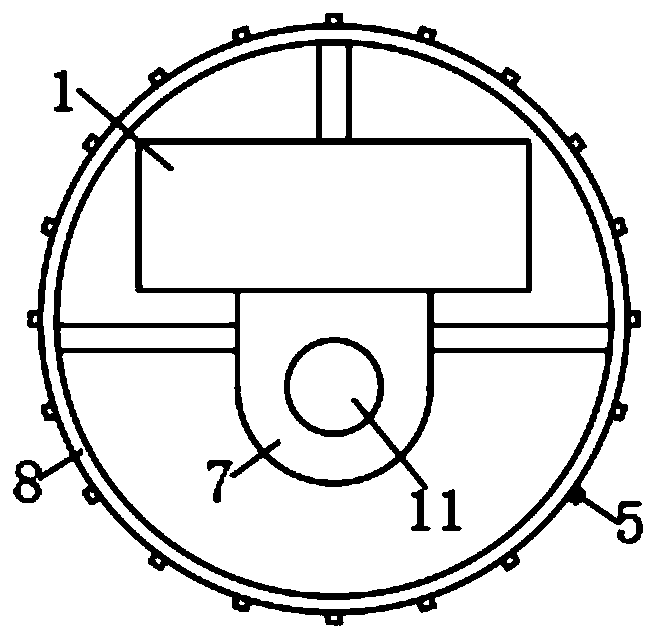

[0024] refer to Figure 1-4 , a dust removal device for a down-the-hole drilling rig used in coal mine development, comprising a drill bit support arm 1 installed on the front side of the down-the-hole drilling rig, and a hydraulic lifting device, a motor, a drill rod 11, a drill bit 6 and a limiter are installed on the drill bit support arm 1 Block 7, the side wall of drill bit support arm 1 runs through and is fixedly connected with device plate 9, is provided with device cavity 12 in device plate 9, is provided with cam 13 in device cavity 12, and the bottom of cam 13 is fixedly connected with ring-shaped slide rail 20, ring-shaped The slide rail 20 is slidably connected with the inner bottom of the device chamber 12 to ensure the normal rotation of the cam 13. The axis of the cam 13 is provided with a circular opening 18, the drill pipe 11 runs through the circular opening 18, and the two side walls of the drill pipe 11 are fixed with The slide bar 10 and the opposite inne...

Embodiment 2

[0029] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the lower end of the limit block 7 is fixedly connected with an annular plate 24 sleeved on the outside of the drill bit 6, the inner side of the annular plate 24 is close to the outer wall of the drill bit 6, and the inner side of the annular plate 24 The side wall is provided with an annular cavity 25, and the outer wall of the annular plate 24 is evenly distributed with a plurality of air outlet holes 23 communicating with the annular cavity 25, and the outer wall of the device plate 9 is provided with a suction pipe 22 communicating with the second cavity 17, and The cavity 17 communicates with the annular cavity 25 through the air outlet pipe 21, the air outlet pipe 21 runs through the limit block 7, and a one-way valve is installed in the air outlet pipe 21 and the suction pipe 22, and the one-way valve in the air outlet pipe 21 makes the air only It can be discharged from the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com