A secondary swirl energy dissipation device for dam cone valves

A technology of energy dissipation devices and cone valves, which is applied in the field of energy dissipation devices and energy dissipation devices for dam cone valves, and can solve the problems of low energy dissipation efficiency of cone valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

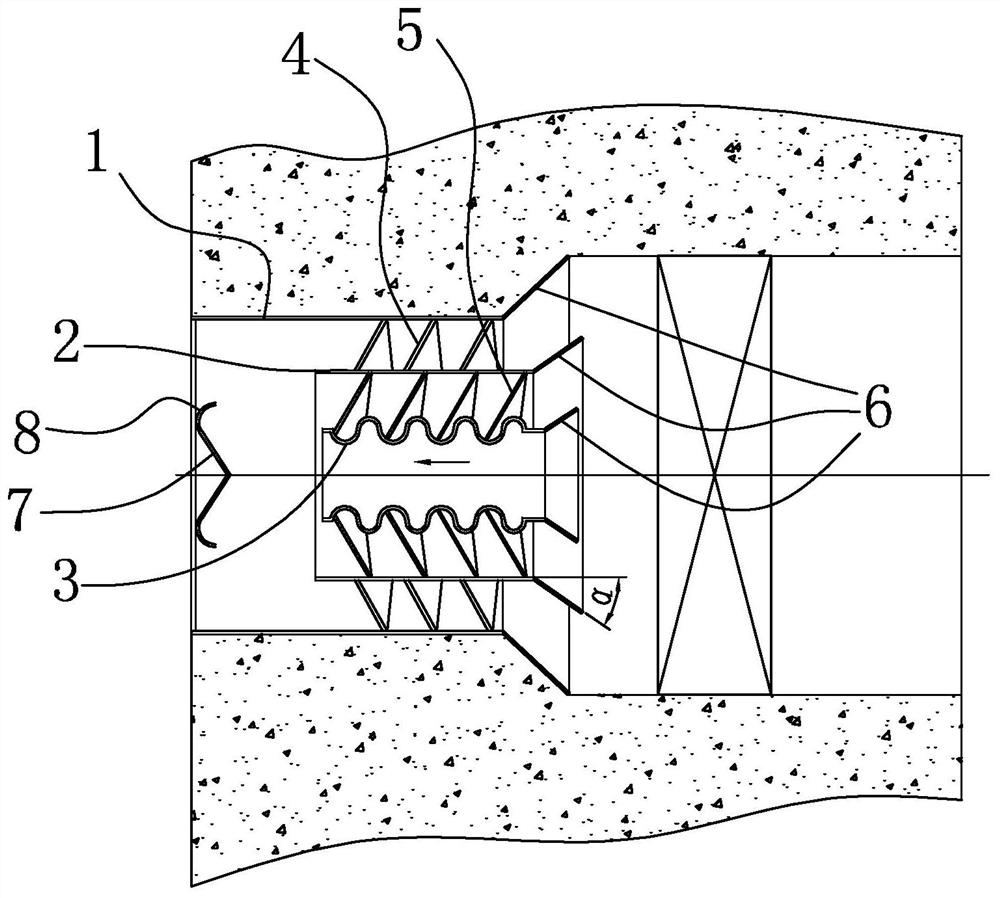

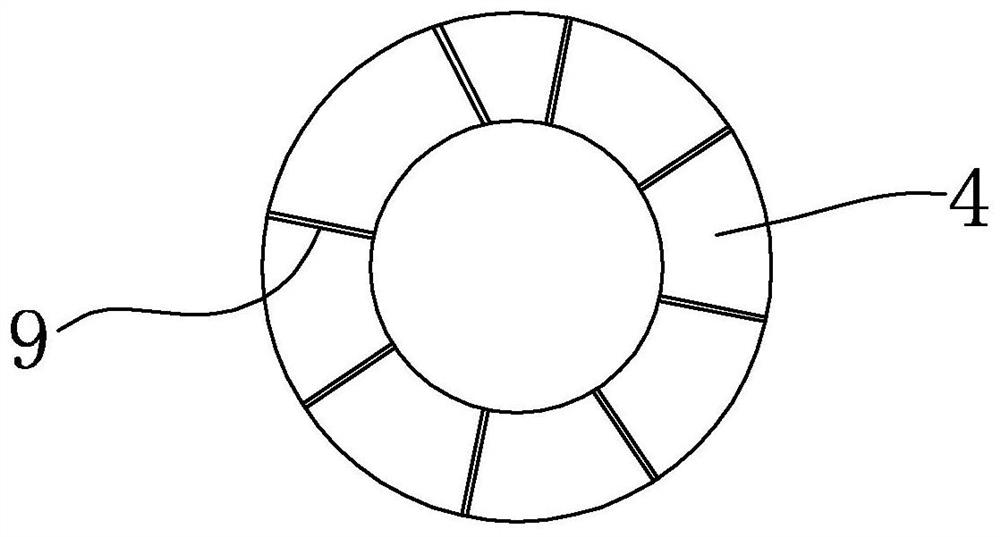

[0016] Specific implementation mode one: combine figure 1 with figure 2 To illustrate this embodiment, this embodiment includes a housing 1, a first sleeve 2, a second sleeve 3, a first helical blade 4 and a second helical blade 5;

[0017] The housing 1, the first sleeve 2 and the second sleeve 3 are sequentially arranged from the outside to the inside and a cavity is formed between the adjacent two, the housing 1, the first sleeve 2 and the second sleeve 3 are concentric, The casing 1, the first sleeve 2 and the second sleeve 3 are all arranged on one side of the outlet of the cone valve, and the cavity between the casing 1 and the first sleeve 2 is provided with a first helical blade 4, and the second A helical blade 4 is fixed on the inner wall of the housing 1, and the cavity between the first sleeve 2 and the second sleeve 3 is provided with a second helical blade 5, and the rotation of the first helical blade 4 and the second helical blade 5 On the contrary, the surf...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 To describe this embodiment, in this embodiment, the end of the outlet side of the first sleeve 2 protrudes from the outlet end of the second sleeve 3 .

[0020] In this way, the water from the shell 1 and the first sleeve 2 and the water from the first sleeve 2 and the second sleeve 3 are first mixed to form water with lower energy and finally mixed with the water from the second sleeve 3 Mix to reduce the energy of the second sleeve 3.

[0021] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 To describe this embodiment, the middle section of the second sleeve 3 in this embodiment is a corrugated sleeve.

[0023] The corrugated sleeve is set so that the water passing through the inner and outer surfaces of the second sleeve 3 generates a swirling flow, and the swirling flow disturbs the water in the second sleeve 3 longitudinally, and at the same time, the effluent water after the swirling flow has a negative impact on the first sleeve 2 and the second sleeve. The outlet water after swirling between the two sleeves 3 plays a transverse shearing effect to eliminate part of the energy of the water; meanwhile, the surface area of the corrugated sleeve is larger than that of the straight tube, which can eliminate part of the energy of the water through friction.

[0024] Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com