Aerial work robot

A high-altitude operation and robot technology, applied in cleaning machinery, applications, cleaning equipment, etc., can solve problems such as difficulty in crossing light bars, falling of high-altitude operation robots, affecting the cleaning of exterior wall glass, etc., to improve cleaning effect and efficiency, increase Clean area, drop-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] see Figure 1-Figure 11 , the specific embodiments of the present invention are as follows:

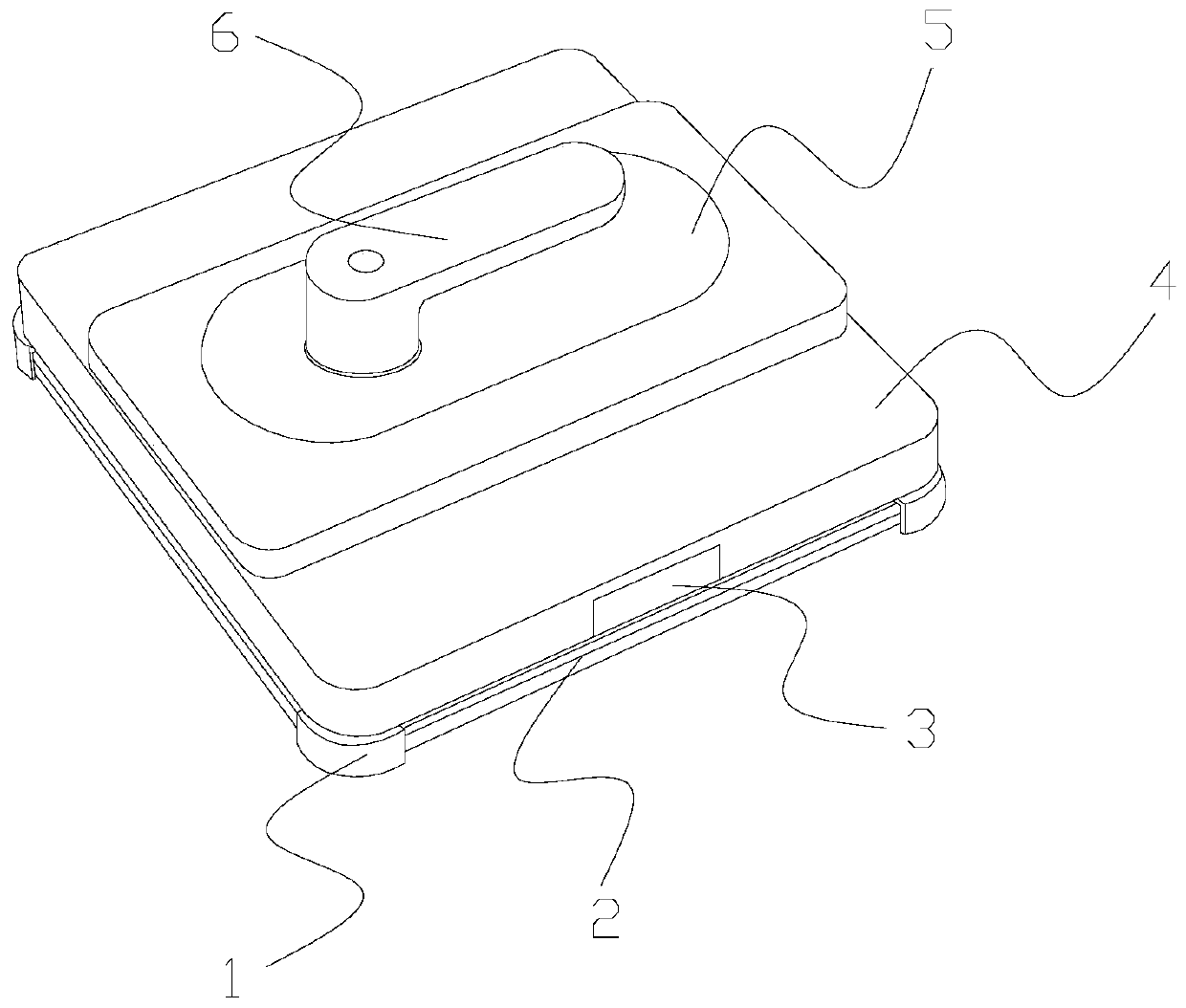

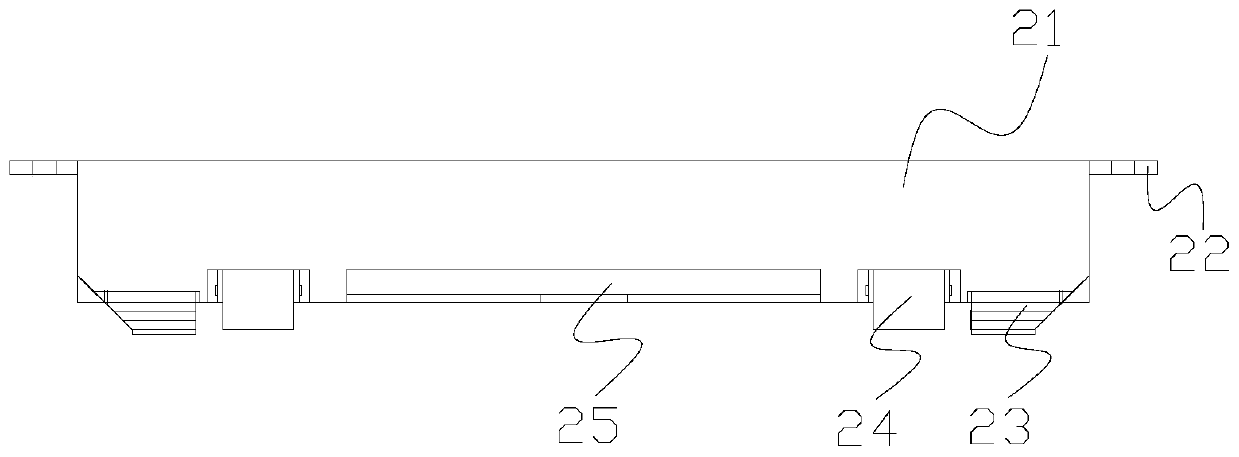

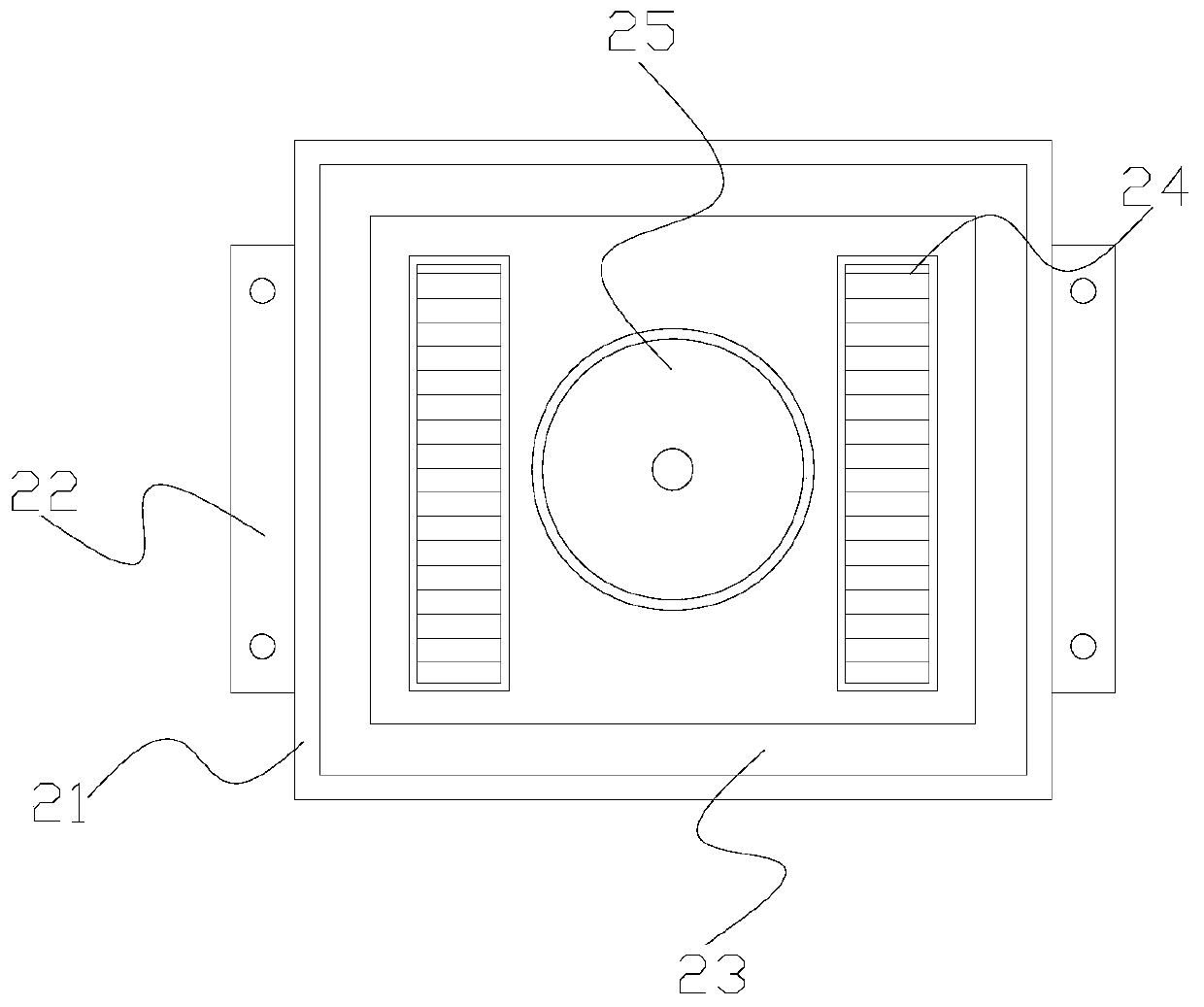

[0030] Its structure includes an edge protection 1, a mobile cleaning structure 2, an edge detection sensor 3, a body 4, a battery box 5, and a handle 6. The edge protection 1 is arranged at the four corners of the mobile cleaning structure 2 and is horizontally installed at the lower end of the body 4. The edge detection sensor 3 is embedded and installed inside the body 4, the battery box 5 is installed horizontally on the upper end of the body 4 and is mechanically connected, the lower end of the handle 6 is embedded in the inside of the battery box 5 and is flexibly connected; the mobile cleaning structure 2 Including a frame 21, a mounting plate 22, a cleaning structure 23, a moving structure 24, and an adsorption chassis 25, the mounting plate 22 is installed on the outside of the frame 21 and welded, and the cleaning structure 23 is horizontally installed on the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com