A detachable box wheel structure

A box wheel and recessed structure technology, applied in the direction of casters, wheels, luggage, etc., can solve the problems of inability to overcome the thermal expansion and contraction of the axles, the inability to fit, the deformation and damage of the hardware card, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

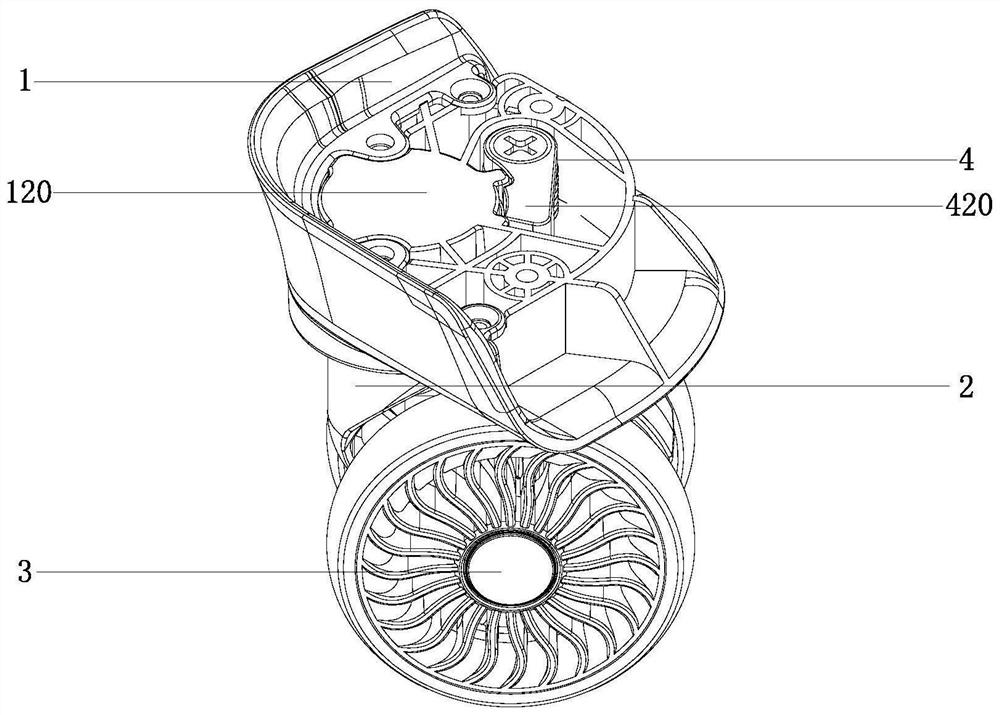

[0033] A detachable box wheel structure, the main body of which is composed of a wheel frame 1, a wheel shaft 2 and a wheel body 3, and one end of the wheel shaft 2 is detachably connected to the wheel frame 1, such as figure 1 shown.

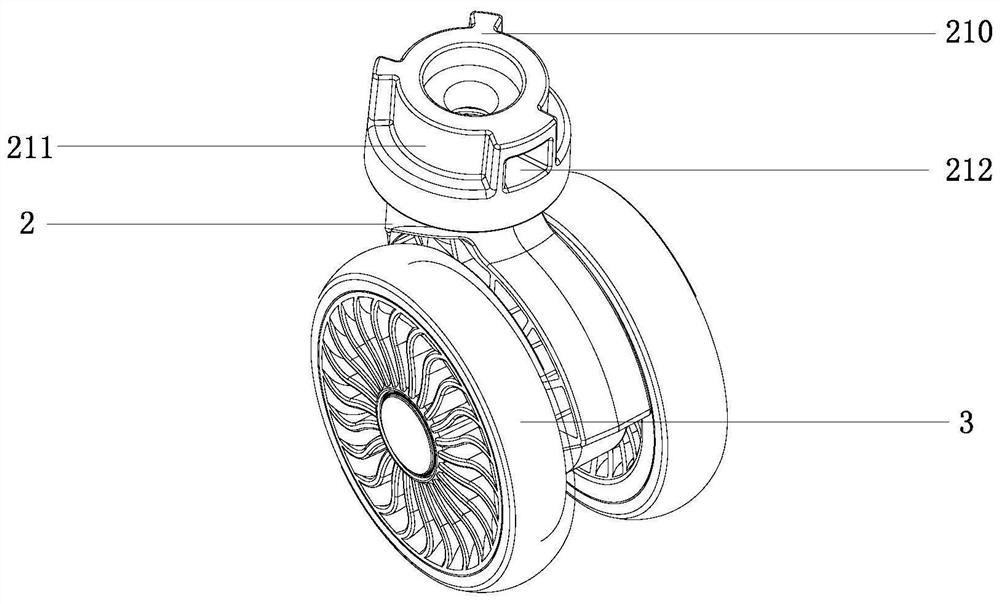

[0034] In this embodiment, an inner wheel frame 210 is provided at one end of the wheel shaft 2 for connecting with the wheel frame 1, such as figure 2 As shown; the inner wheel frame 210 is integrally formed by injection molding, and is sleeved on one end of the wheel shaft 2, and the wheel shaft 2 can rotate horizontally relative to the inner wheel frame 210; the wheel shaft 2 cooperates with the wheel frame 1 through the inner wheel frame 210 connect.

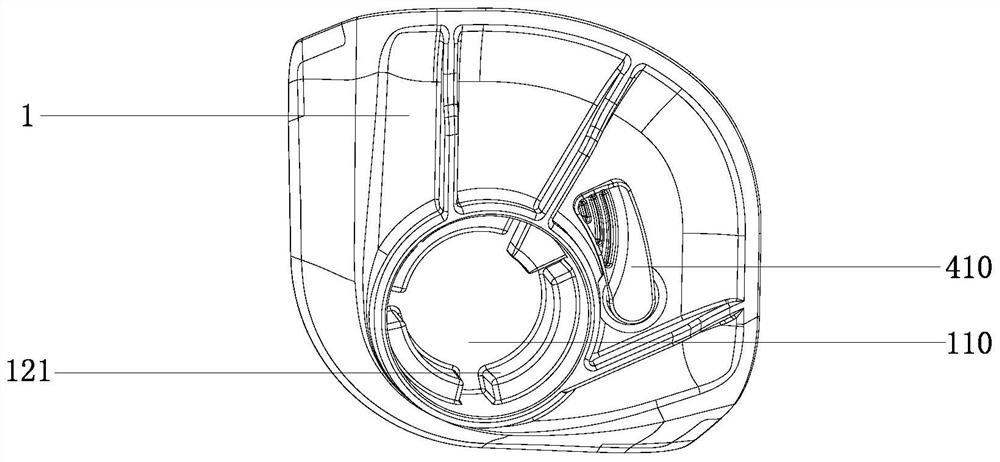

[0035] In this embodiment, the wheel frame 1 is provided with a first through hole 110, and the inner wheel frame 210 can be fitly inserted into the first through hole 110; the upper surface of the wheel frame 1 is provided with a cover plate 120, the cover plate 120 is blocked at its top ...

Embodiment 2

[0043] This embodiment differs from Embodiment 1 in that the outer wall of the inner wheel frame 2 is provided with threads, the first through hole 110 is provided with threads that match the inner wheel frame 210, and the inner wheel frame 210 The detachable connection between the wheel shaft 2 and the wheel frame 1 is realized through threaded connection with the first through hole 110 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com