Assembly tool for communicating pipeline of fuel system and assembly method thereof

A technology for connecting pipelines and fuel systems, which is applied in the field of assembly tools for fuel system connecting pipelines, can solve the problems affecting the production and delivery cycle of aircraft, low work efficiency, and small active area, so as to shorten the riveting assembly cycle, improve the installation quality, and reduce stress. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to specific embodiments.

[0020] The fuel system communication pipe assembling tool of the invention replaces the traditional completely manual installation method to install the soft, same outer diameter and interference fit communication pipes between two fuel tanks on the aircraft fuel system.

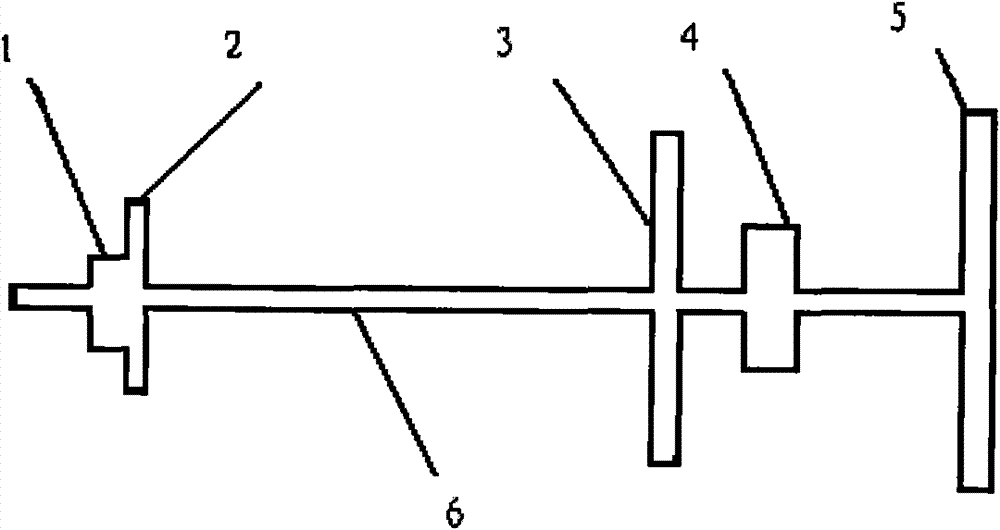

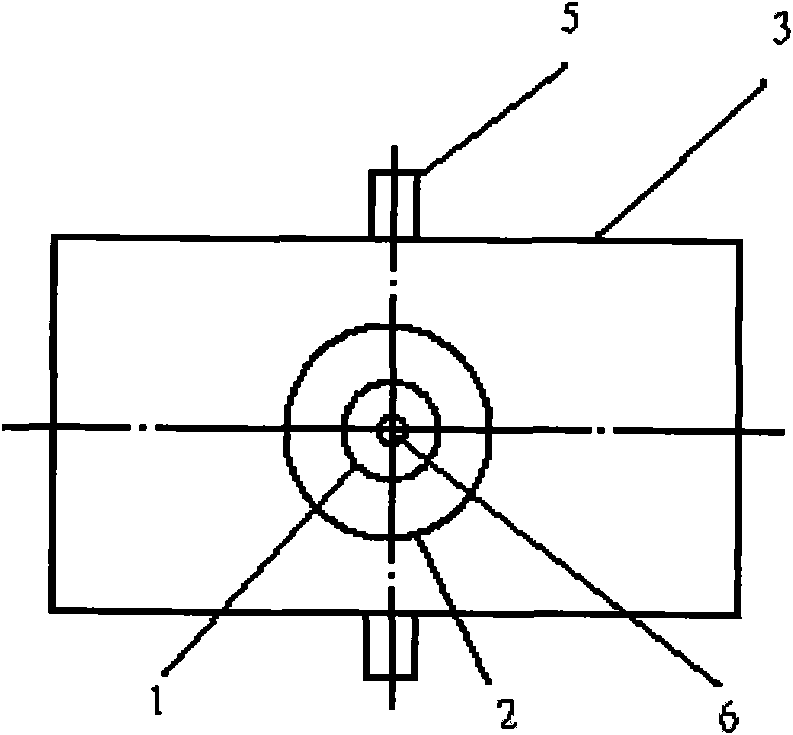

[0021] see figure 1 , which is a schematic structural diagram of the fuel system communication pipeline assembly tool of the present invention. The fuel system communication pipeline assembly tool includes a positioning nut 1 , a front baffle 2 , a rear baffle 3 , a compression nut 4 , a handle 5 , and a pull rod 6 . One end of the pull rod is screwed on the handle 5 , and the compression nut 4 , the rear baffle 3 , the front baffle 2 and the positioning bolt 1 are all mounted on the pull rod 6 . The compression nut 4 is installed between the rear baffle and the handle 5 , the front baffle 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com