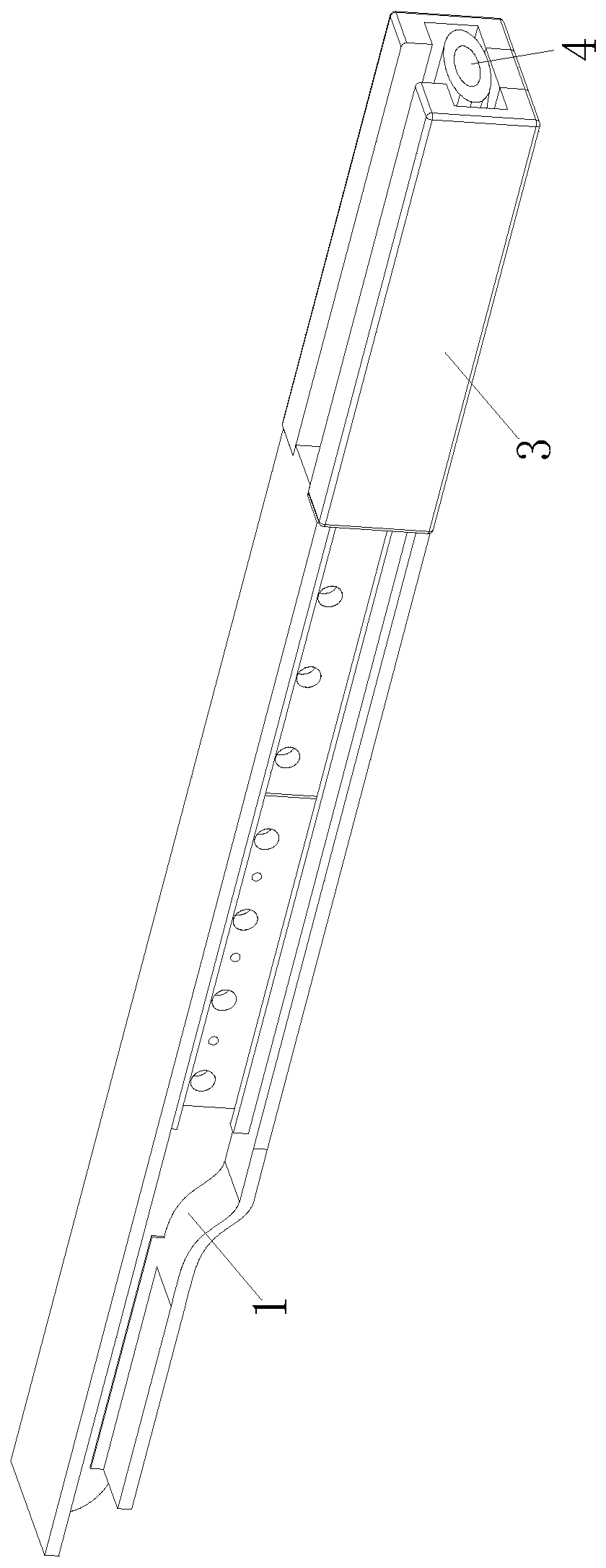

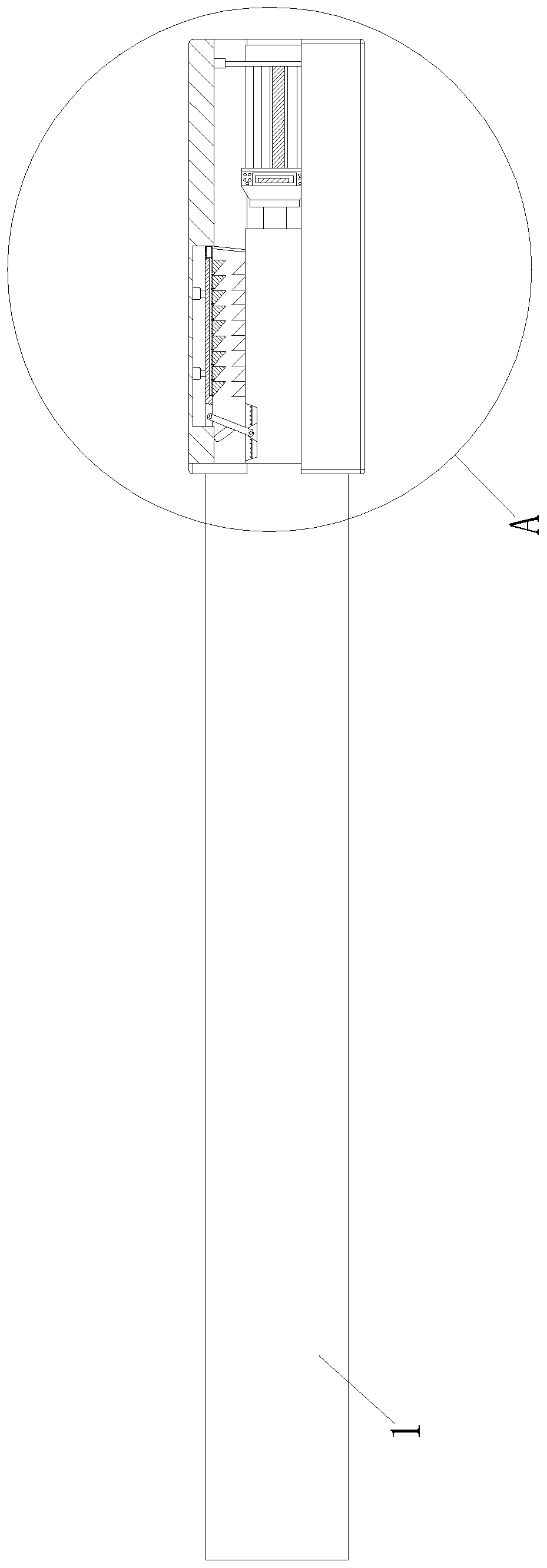

Semi-trailer longitudinal beam assembly

A longitudinal beam assembly and semi-trailer technology, which is applied to vehicle components, substructure, transportation and packaging, etc., can solve problems such as container falling off, safety accidents, and difficulty in fixing the container position, so as to enhance strength and reliability, reduce Replacement and repair costs, guaranteed use and service life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

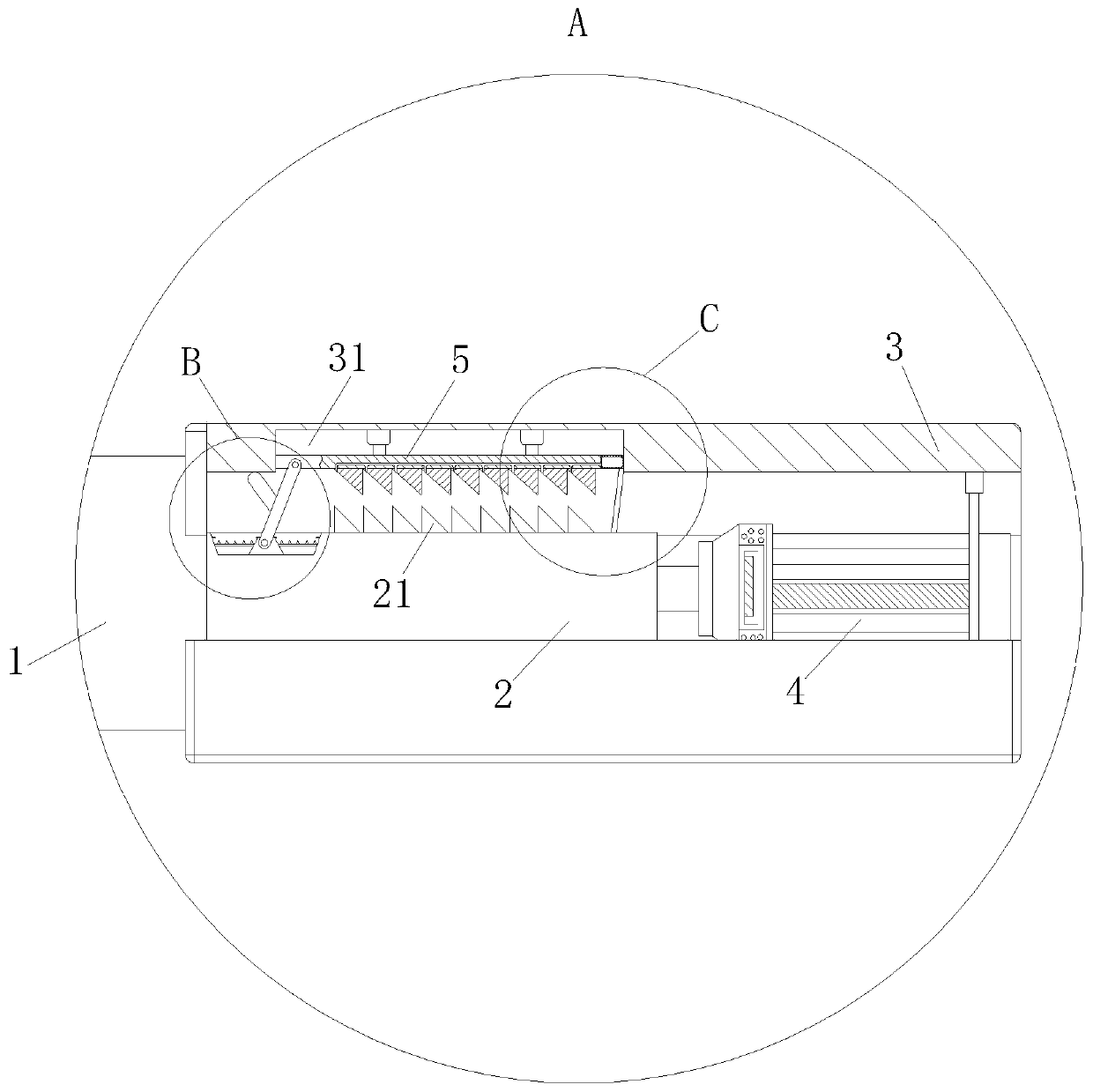

[0023] As an embodiment of the present invention, a No. 2 chute 22 is opened on the side wall of the top column 2; a slider 221 is slidably connected in the No. 2 chute 22; the slider 221 and the locking plate 51 A connecting rod 512 is arranged between, one end of the connecting rod 512 is hinged on the slider 221, the other end of the connecting rod 512 is hinged on the bayonet plate 51, and the connecting rod 512 is provided with a support rod 513, so that the support rod 513 and the sleeve 3 side wall contact; strengthen the strength and reliability of the locking unit 5 through the cooperation of the slider 221 and the connecting rod 512; during operation, when the length of the longitudinal beam assembly needs to be adjusted according to the container of different length, the air pump is controlled by the controller Supply air to the cylinder 4, so that the cylinder 4 expands and contracts, thereby pushing the top column 2 to slide in the sleeve 3. During the expansion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com