A kind of cationic polyacrylamide and its application

A polyacrylamide, cationic technology, used in flocculation / sedimentation water / sewage treatment and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

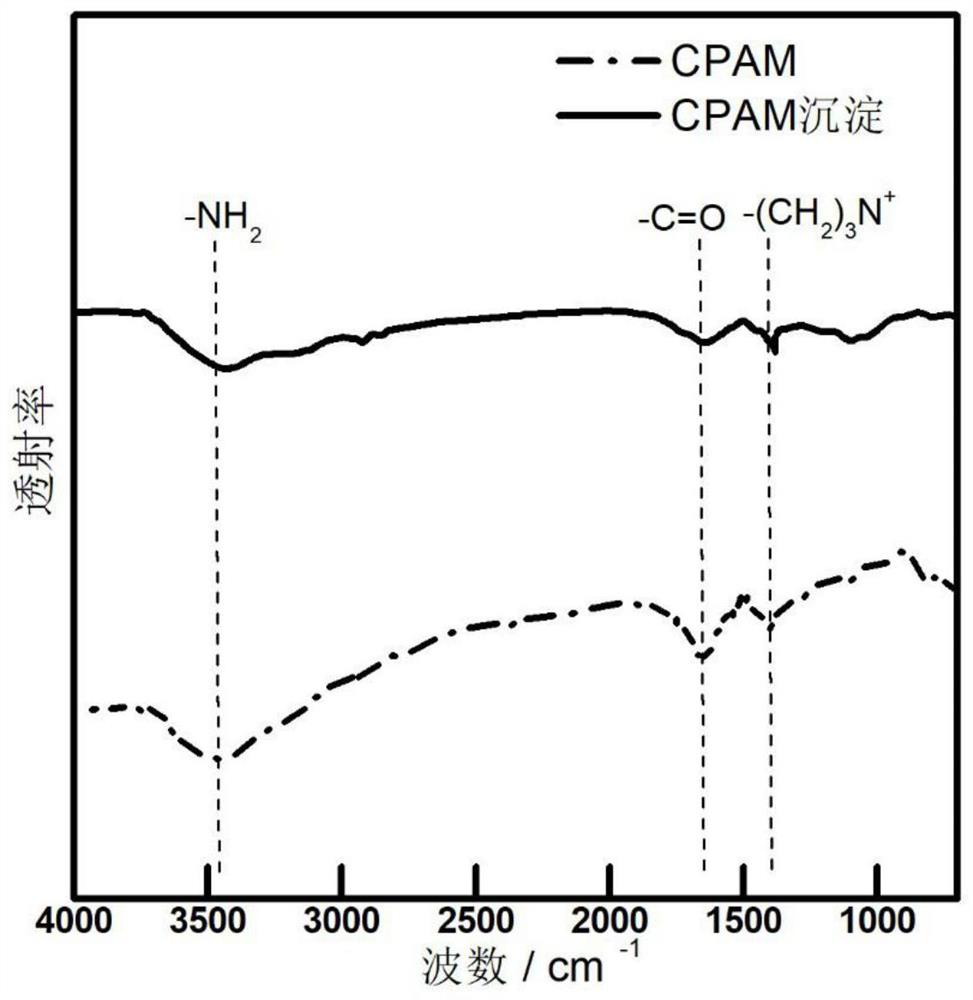

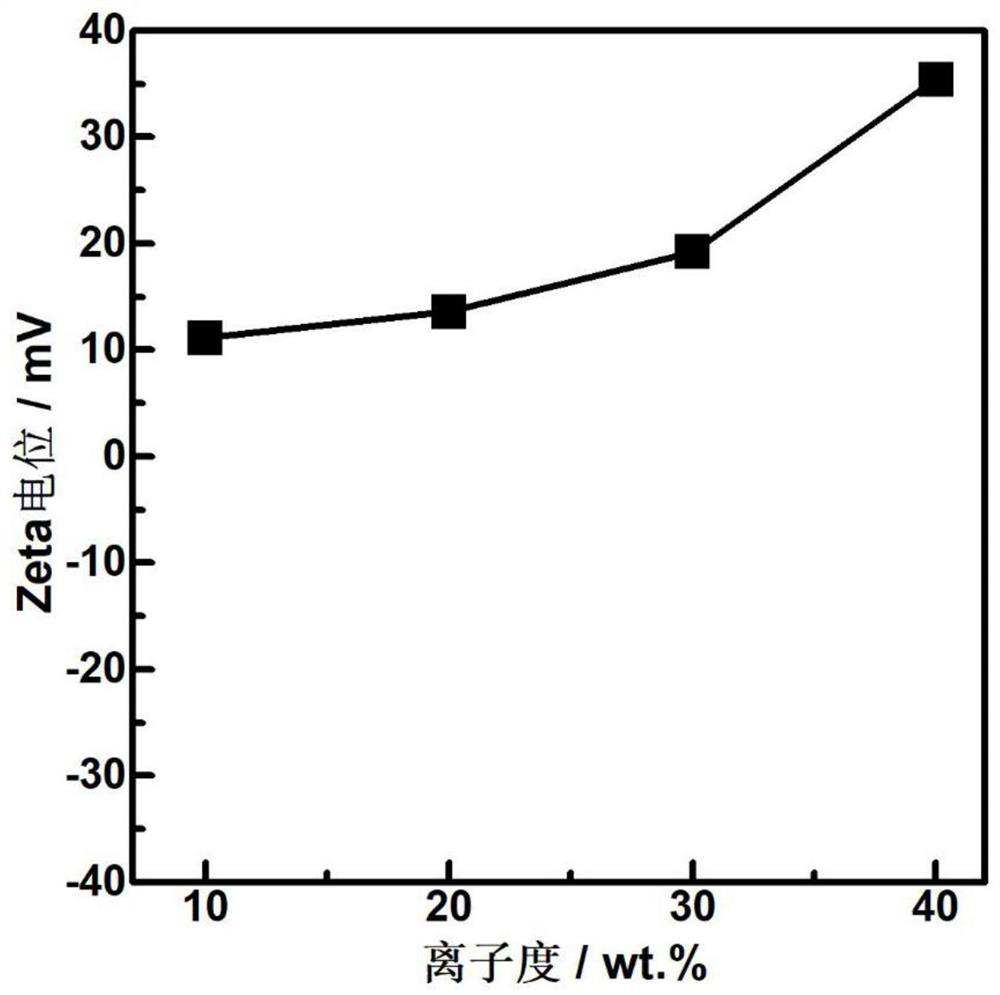

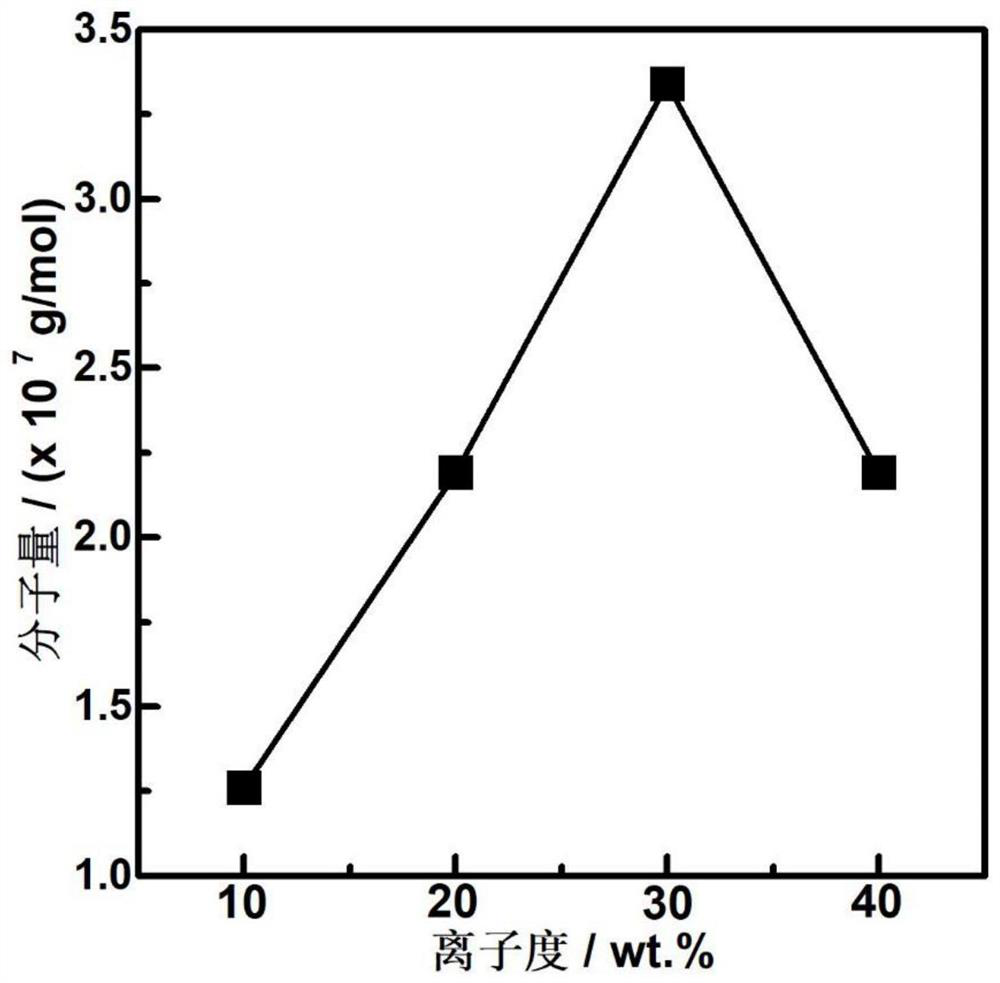

[0042]Add 21g of acrylamide, 2.33g of dimethyl diallyl ammonium chloride, 0.1g of urea, and 0.1g of EDTA into a 1L three-necked flask in sequence, and dissolve them in 70mL of deionized water to prepare a salt solution A, which is protected by nitrogen gas. , mechanically stirred at a speed of 300r / min for 30min. Prepare Initiator B containing 0.0053 g ammonium persulfate, 0.0125 g sodium borohydride, 0.0125 g azobisisobutylamidine hydrochloride and 1.5 mL deionized water. The prepared initiator B was added dropwise to the salt solution A with a peristaltic pump, and the dropping time was 30 minutes. After the dropwise addition, the reaction temperature was raised to 50°C, and the reaction was continued for 2-3 hours until the solution became a transparent colloid. The jelly sample was taken out and placed in an evaporating dish and dried at a constant temperature of 75° C. to a constant weight to obtain a cationic polyacrylamide (10-CPAM) with an ionicity of 10 wt.%.

[004...

Embodiment 2

[0046] Add 21g of acrylamide, 5.25g of dimethyl diallyl ammonium chloride, 0.1g of urea, and 0.1g of EDTA into a 1L three-necked flask in sequence, and dissolve them in 70mL of deionized water to prepare a salt solution A, which is protected by nitrogen gas. , mechanically stirred at a speed of 300r / min for 30min. Prepare Initiator B containing 0.0053 g ammonium persulfate, 0.0125 g sodium borohydride, 0.0125 g azobisisobutylamidine hydrochloride and 1.5 mL deionized water. The prepared initiator B was added dropwise to the salt solution A with a peristaltic pump, and the dropping time was 30 minutes. After the dropwise addition, the reaction temperature was raised to 50°C, and the reaction was continued for 2-3 hours until the solution became a transparent colloid. Take out the jelly sample and place it in an evaporating dish and dry it at a constant temperature of 75°C to a constant weight to obtain a cationic polyacrylamide with an ionization of 20wt.%.

Embodiment 3

[0048] Add 21g of acrylamide, 9g of dimethyl diallyl ammonium chloride, 0.1g of urea, and 0.1g of EDTA in sequence in a 1L three-necked flask, and dissolve them in 70mL of deionized water to prepare a salt solution A, which is protected by nitrogen gas. Stir mechanically at a speed of 300r / min for 30min. Prepare Initiator B containing 0.0053 g ammonium persulfate, 0.0125 g sodium borohydride, 0.0125 g azobisisobutylamidine hydrochloride and 1.5 mL deionized water. The prepared initiator B was added dropwise to the salt solution A with a peristaltic pump, and the dropping time was 30 minutes. After the dropwise addition, the reaction temperature was raised to 50°C, and the reaction was continued for 2-3 hours until the solution became a transparent colloid. Take out the jelly sample and place it in an evaporating dish and dry it at a constant temperature of 75°C until it reaches a constant weight to obtain a cationic polyacrylamide with an ion content of 30wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com