Kitchen oil smoke purification device and method for catering industry

A technology of oil fume purification and equipment, which is applied in chemical instruments and methods, oil fume removal, separation methods, etc., can solve problems such as air pollution, large oil fume emission density and discharge volume, and large fire safety hazards, and achieve the effect of efficient purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

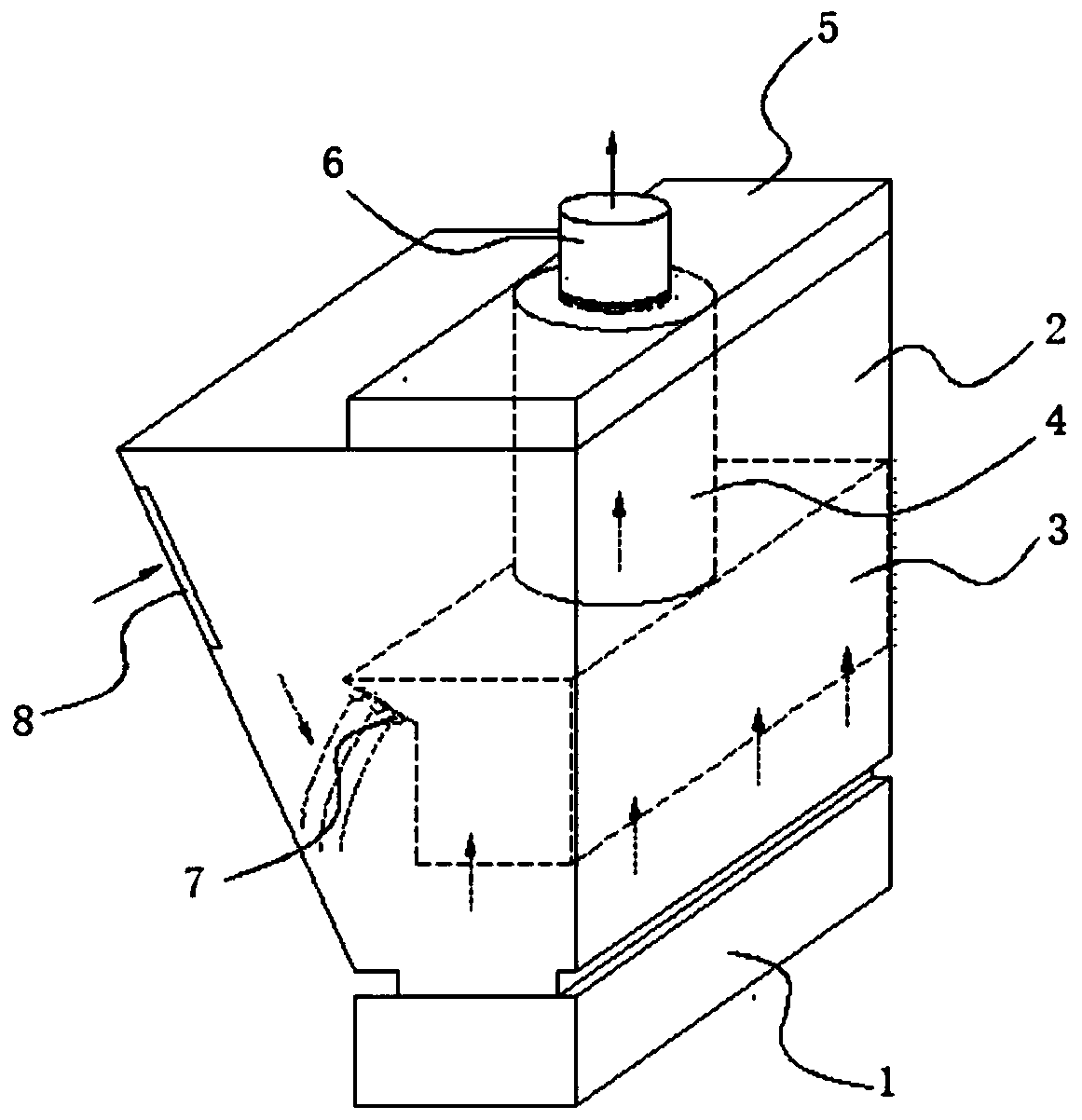

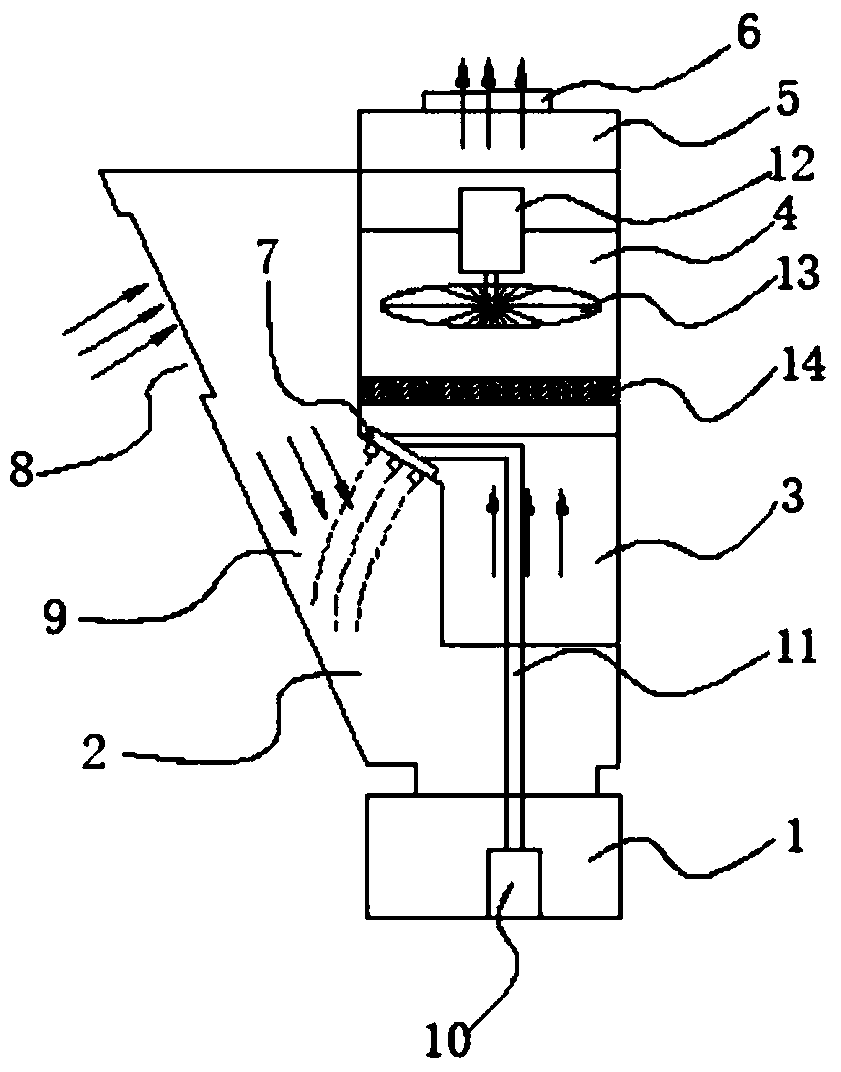

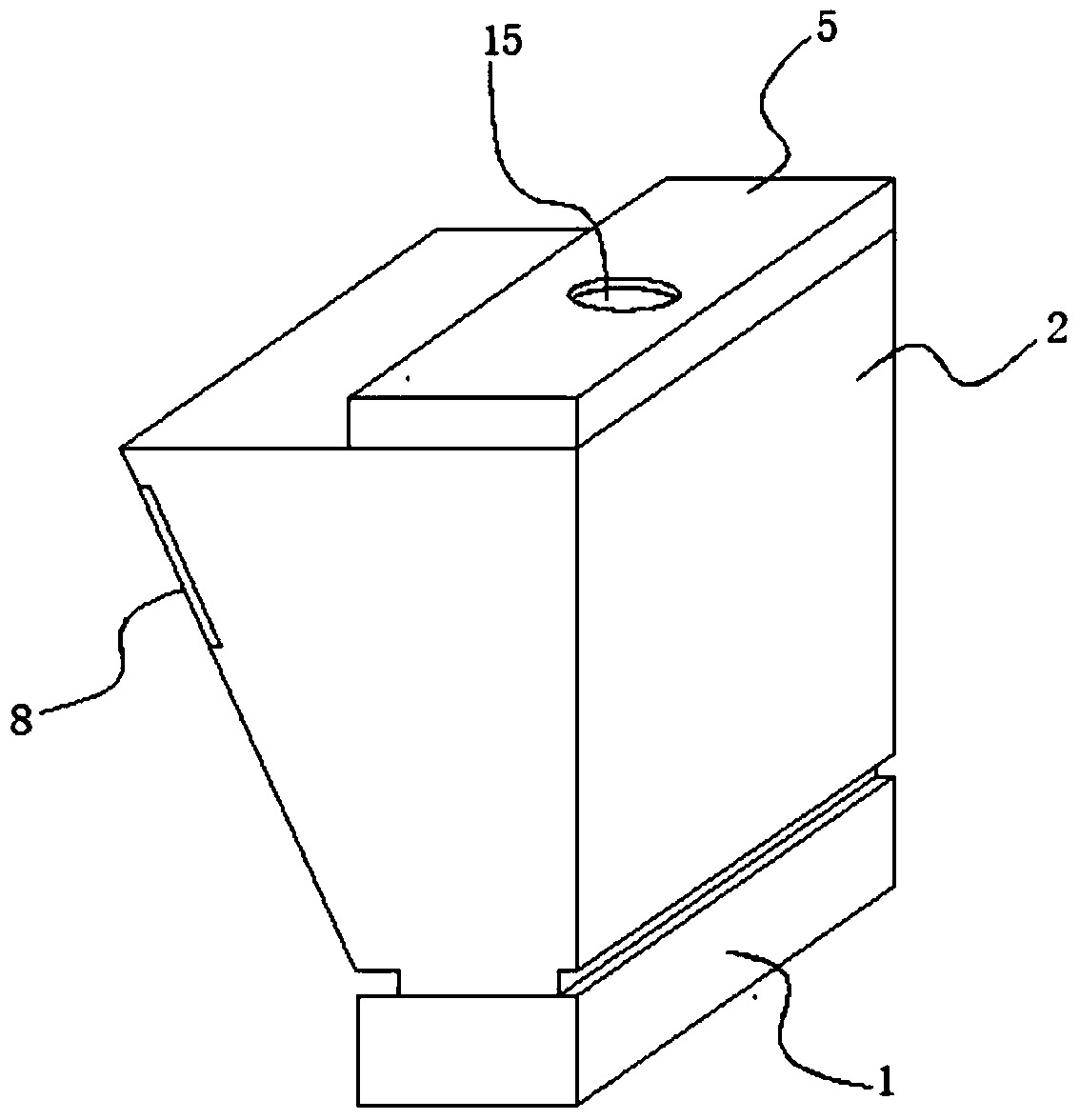

[0029] Such as figure 1 and figure 2 As shown, a cooking oil fume purification equipment for the catering industry provided by the embodiment of the present invention includes a water storage tank 1 on which a purification tank 2 is fixed, and the purification tank 2 is an inverted right-angled trapezoidal structure. A flow-limiting box 3 is fixed inside the box 2, and a delivery cylinder 4 is fixedly connected to the flow-limiting box 3, and an exhaust joint 6 is connected to the upper end of the delivery cylinder 4, and the inclined surface of the purification box 2 is connected with the flow-limiting An air flow channel 9 is left between the boxes 3, and a spray device 7 for covering the air flow channel 9 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com