Butterfly valve with sealing protection structure

A seal protection, butterfly valve technology, applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of soft sealing layer damage of valve plates, shortened service life of valves, etc., to reduce forced shutdowns, prolong service life, protect The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

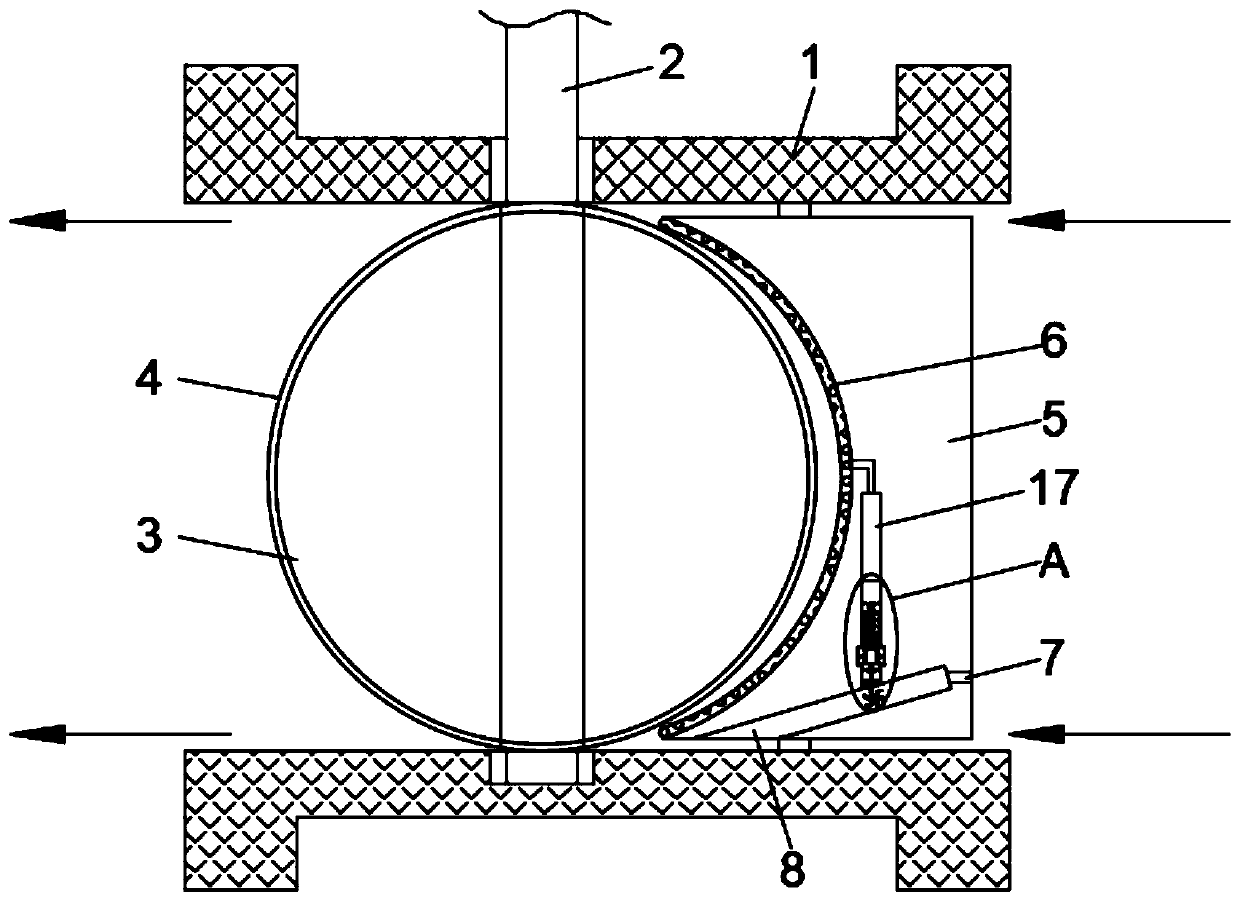

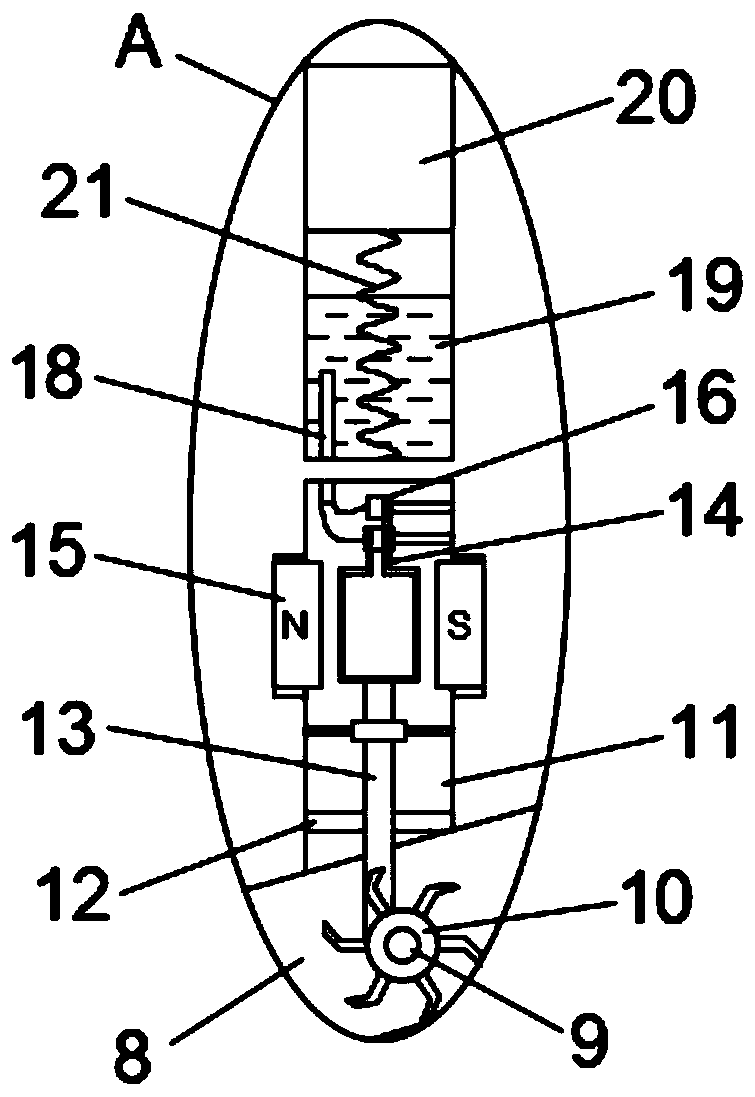

[0013] refer to Figure 1-2 , a butterfly valve with a sealing protection structure, including a butterfly valve body 1, a valve stem 2 and a valve plate 3, a soft sealing layer 4 is provided on the side of the valve plate 3, and a protective seat 5 is fixedly connected to the right end of the valve plate 3 to protect The left side of the seat 5 adopts an arc-shaped structure, and the surface of the arc-shaped structure is fixedly attached with a strip-shaped elastic airbag 6, and the right side of the protective seat 5 is provided with a horizontal water inlet 7, and the water inlet 7 is connected with a slope. A water outlet 8 is provided, and the lower end of the water outlet 8 is located at the bottom of the protection seat 5;

[0014] The inside of the protective seat 5 is also provided with a transmission mechanism that is used in conjunction with the strip-shaped elastic airbag 6. The transmission mechanism includes a first rotating shaft 9 that is rotatably connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com