Display mounting assembly in vehicle

A vehicle interior and display technology, applied to vehicle components, transportation and packaging, etc., can solve problems such as unfavorable disposal measures, inability to adjust angles, and high potential safety hazards, so as to reduce observation obstacles and visual fatigue, improve driving safety, and assemble The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

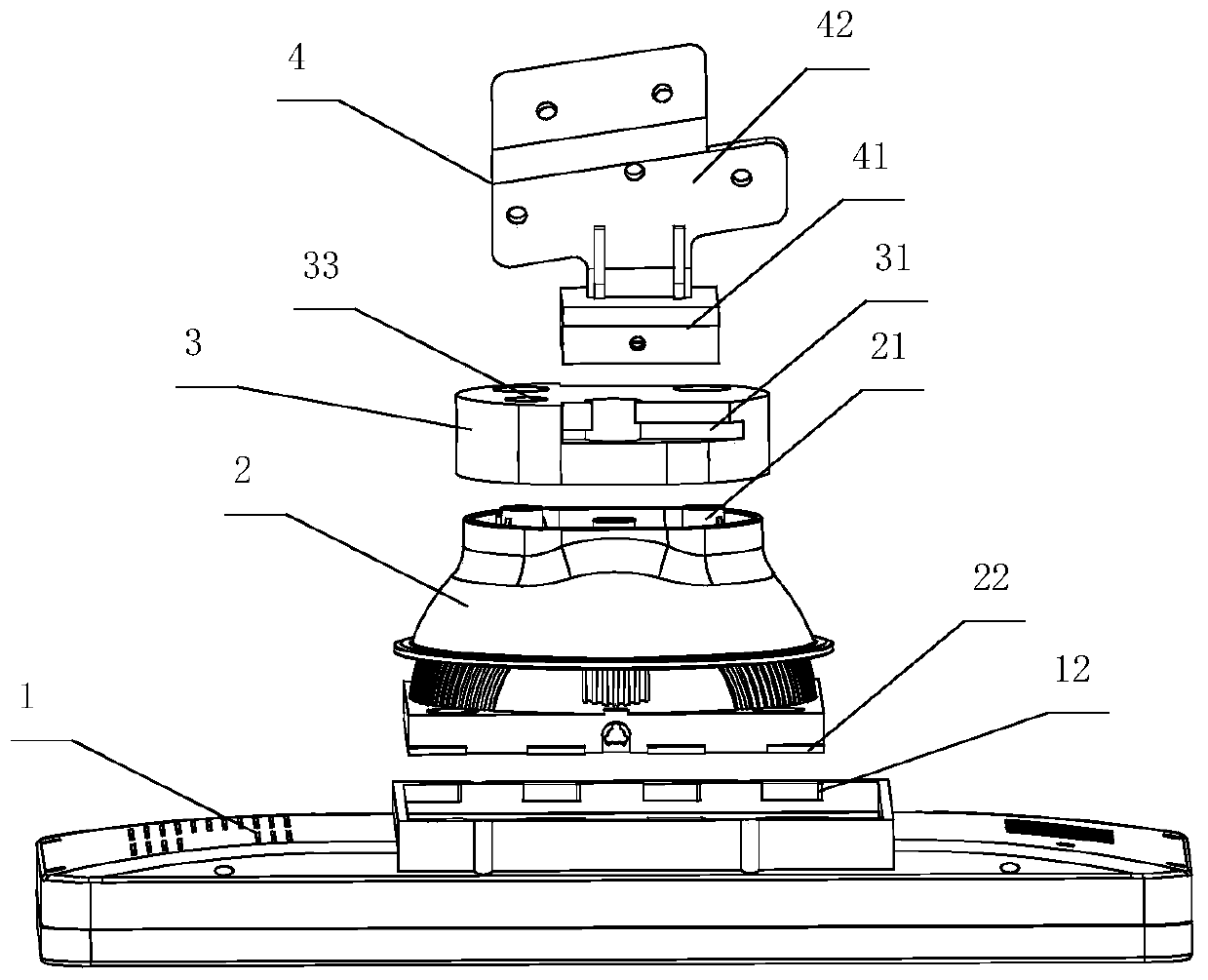

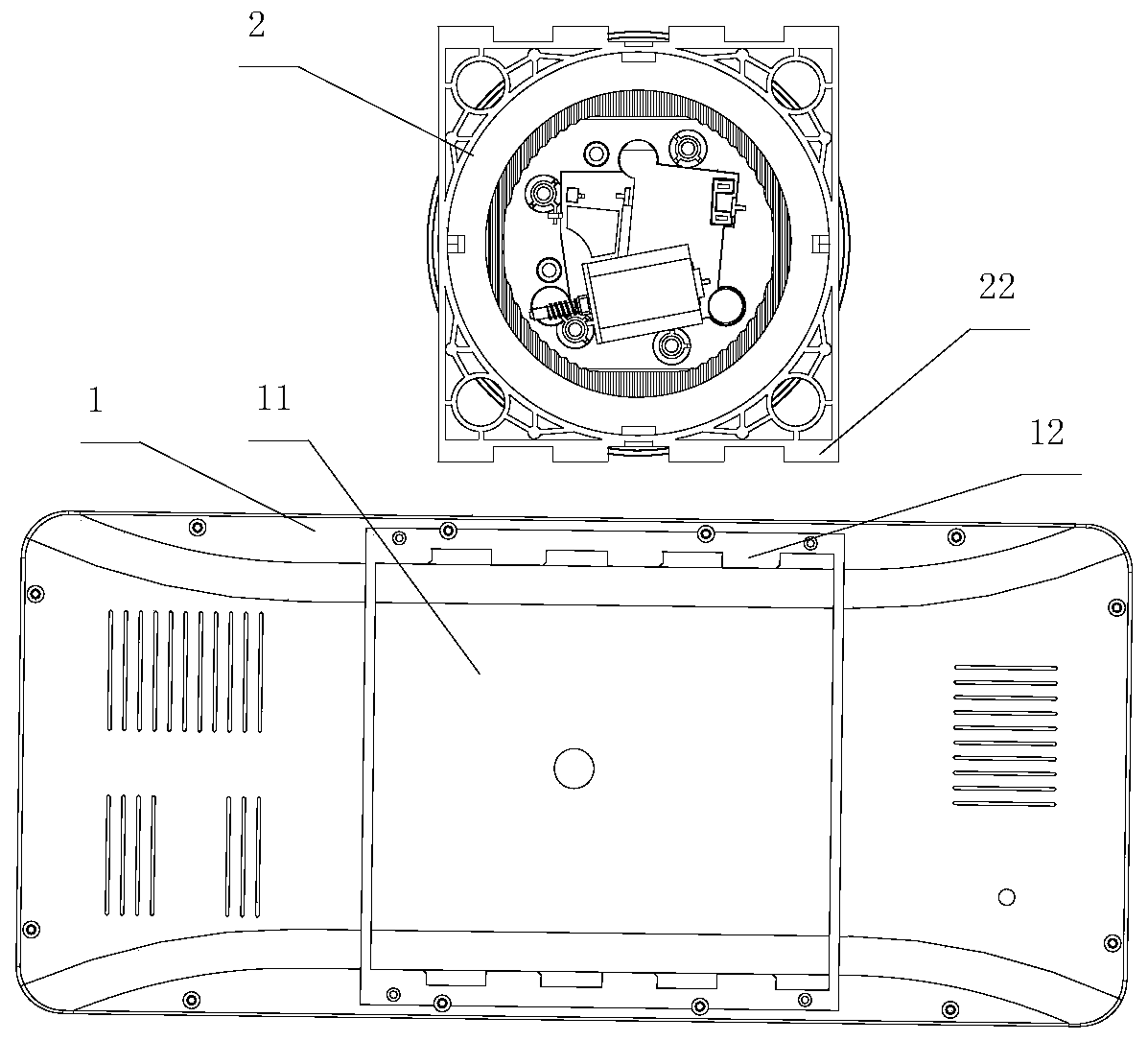

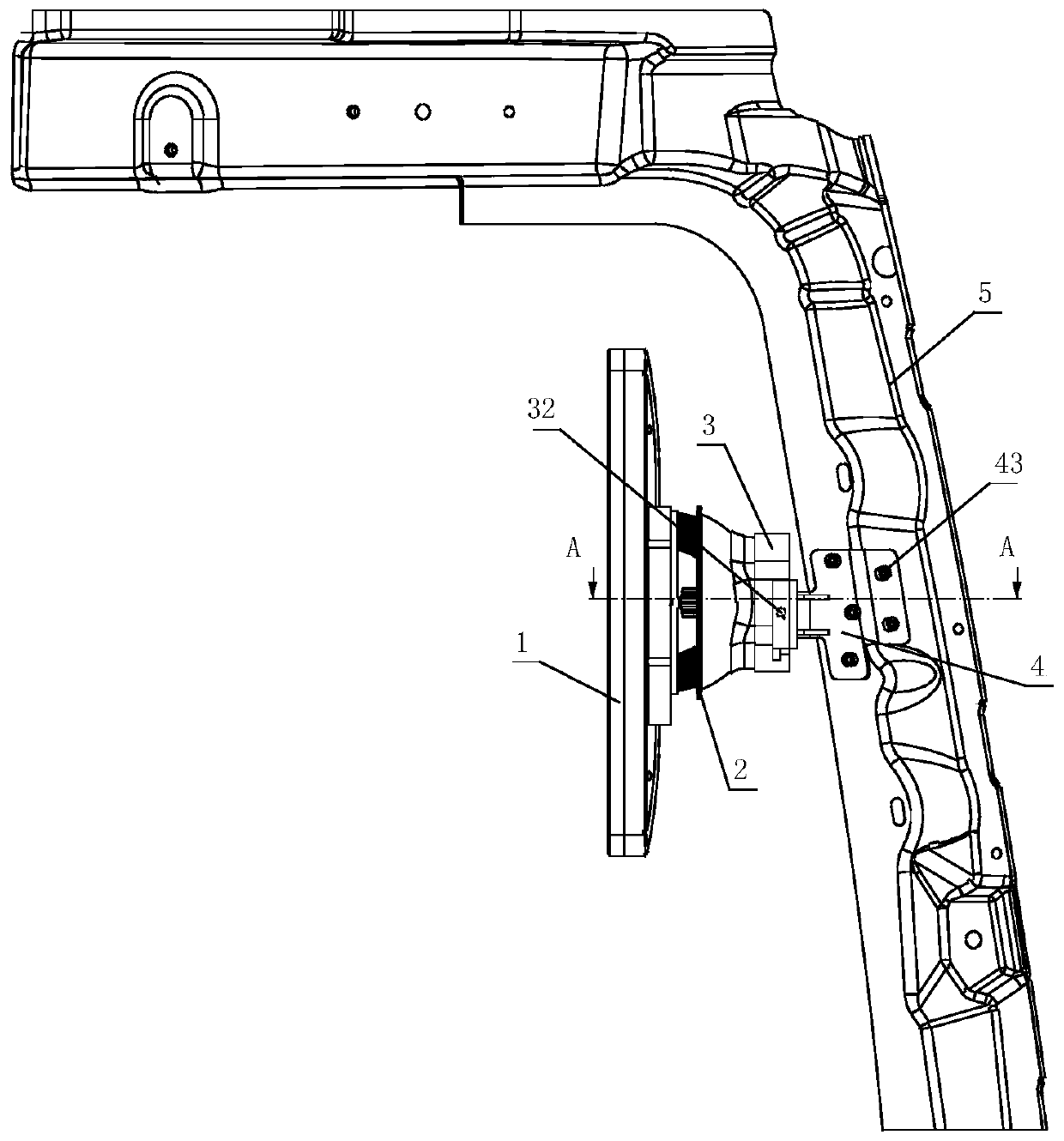

[0030] Example 1, such as Figure 1 to Figure 4 As shown, the display installation assembly provided by the present application can be used to install two left and right displays 1 inside the vehicle, so as to respectively display the environmental conditions on both sides outside the vehicle correspondingly.

[0031] Specifically, the display 1 is installed at the A-pillar of the vehicle body frame, and the installation assembly includes a connecting block 3 for connecting the driver 2, and a connecting bracket 4 installed on the sheet metal part 5 of the A-pillar;

[0032] The driver 2 has a vertical guide post 21 with a threaded hole, and the connecting block 3 has a vertical through hole 33 , and bolts pass through the through hole 33 and the guide post 21 in turn for fastening connection.

[0033] A rectangular slot 11 is opened on the back of the display 1 , and two rows of saw-toothed stoppers 12 are arranged in the rectangular slot 11 , and a saw-toothed baffle 22 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com