Pressing device for automatic tobacco braiding machine

A technology of a pressing device and a cigarette weaving machine, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of lack of ventilation auxiliary structure, lack of pressing mechanism, and influence on air-drying speed, so as to improve ventilation effect and improve clamping. effect, the effect of improving the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

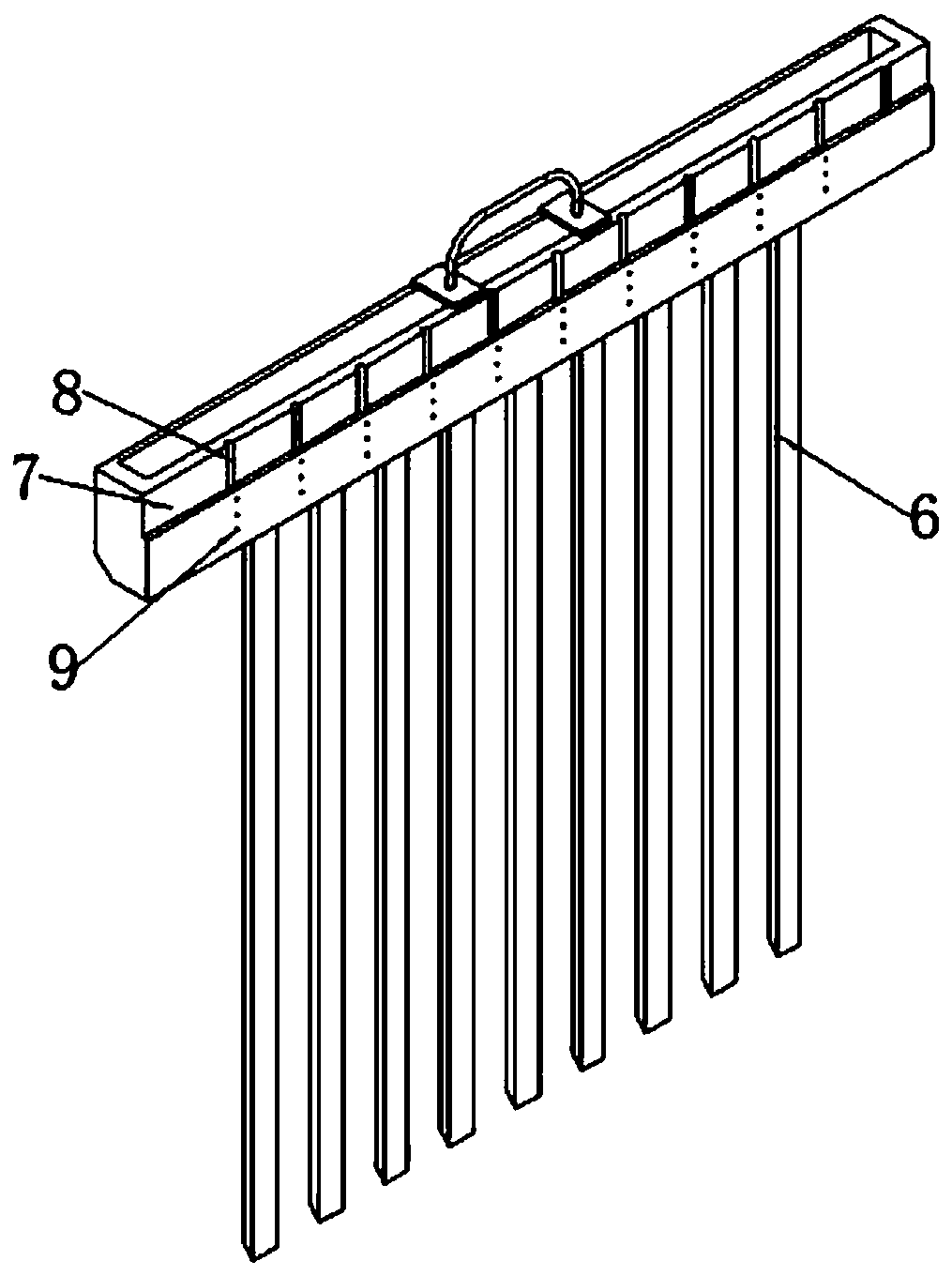

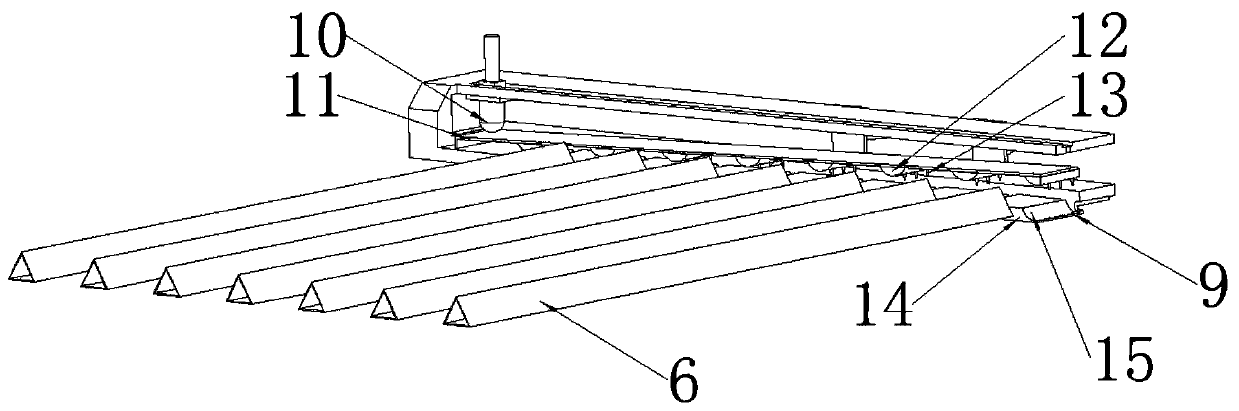

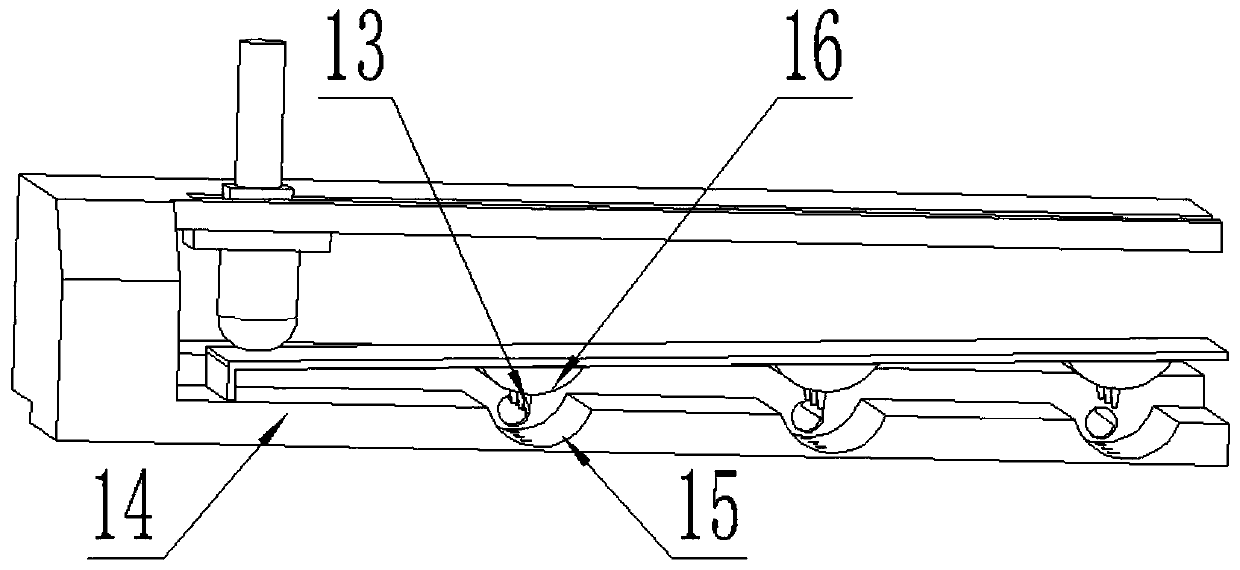

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The present invention provides based on garden greening environmental protection ecological landscape pavilion, comprises upper clamp seat 1 and lower clamp seat 14; Described upper clamp seat 1 and lower clamp seat 14 have constituted the clamp seat body mechanism of a rectangular clamp chamber type, wherein There is a chute 4 with a sinker cavity structure on the clamping seat 1; a sliding seat 5 in the style of a hand-held column is slidingly fitted in the chute 4, and the inner end of the sliding seat 5 is a cylindrical arc surface The sliding pressure column 10; the inner cavity surface of the lower clamping seat 14 is welded with a spring plate 11, and the spring plate 11 is set in the left low right high seesaw type; the bottom right area of the spring plate 11 is provided with a row of Solid clamping bases 12, and these clamping bases 12 are semi-arc-shaped, and their bottom ends are welded with a row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com