A laser precision machining method for dense holes

A technology of precision machining and laser processing head, which is applied in the direction of metal processing equipment, laser welding equipment, manufacturing tools, etc. It can solve the problems that it is difficult to apply to large-area and high-density group hole processing, low processing efficiency, and low hole quality. The effect of less surface burrs, high processing efficiency and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

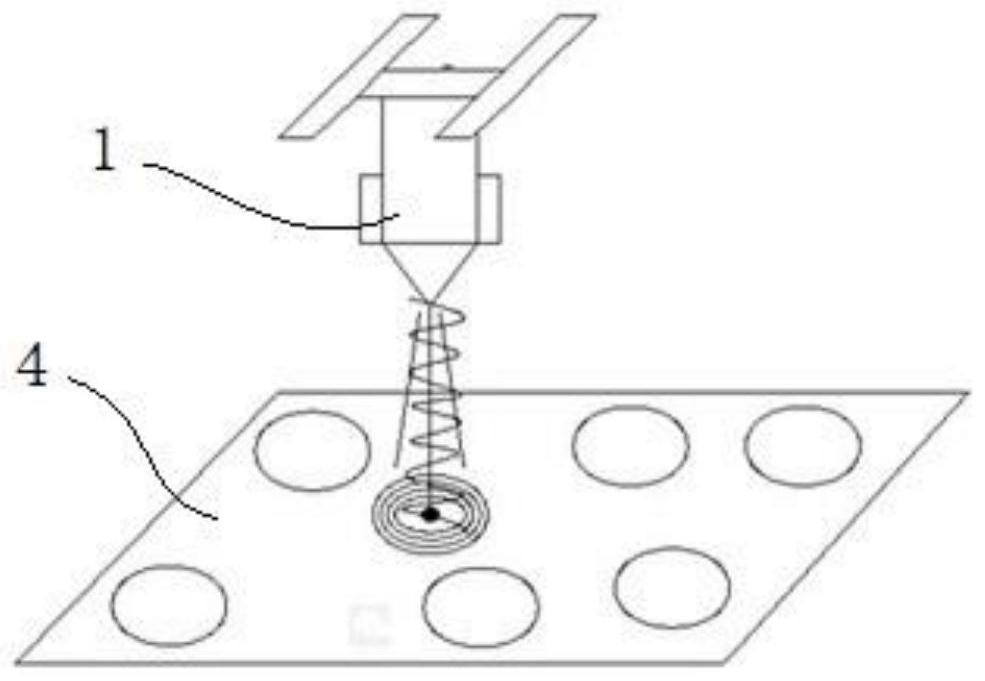

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

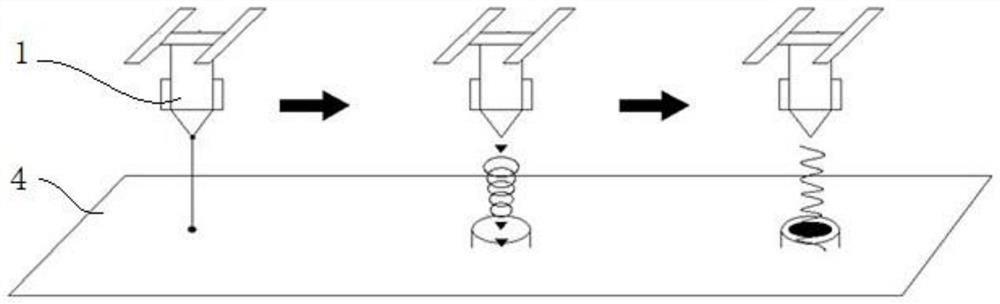

[0034] A laser precision processing method for dense holes of the present invention, the processing method comprises: driving the laser processing head to move to the position of the hole to be processed in the substrate through a long-stroke movement mechanism, and driving the laser processing head to the position of the hole to be processed in the substrate through a micro-motion mechanism Perform laser drilling.

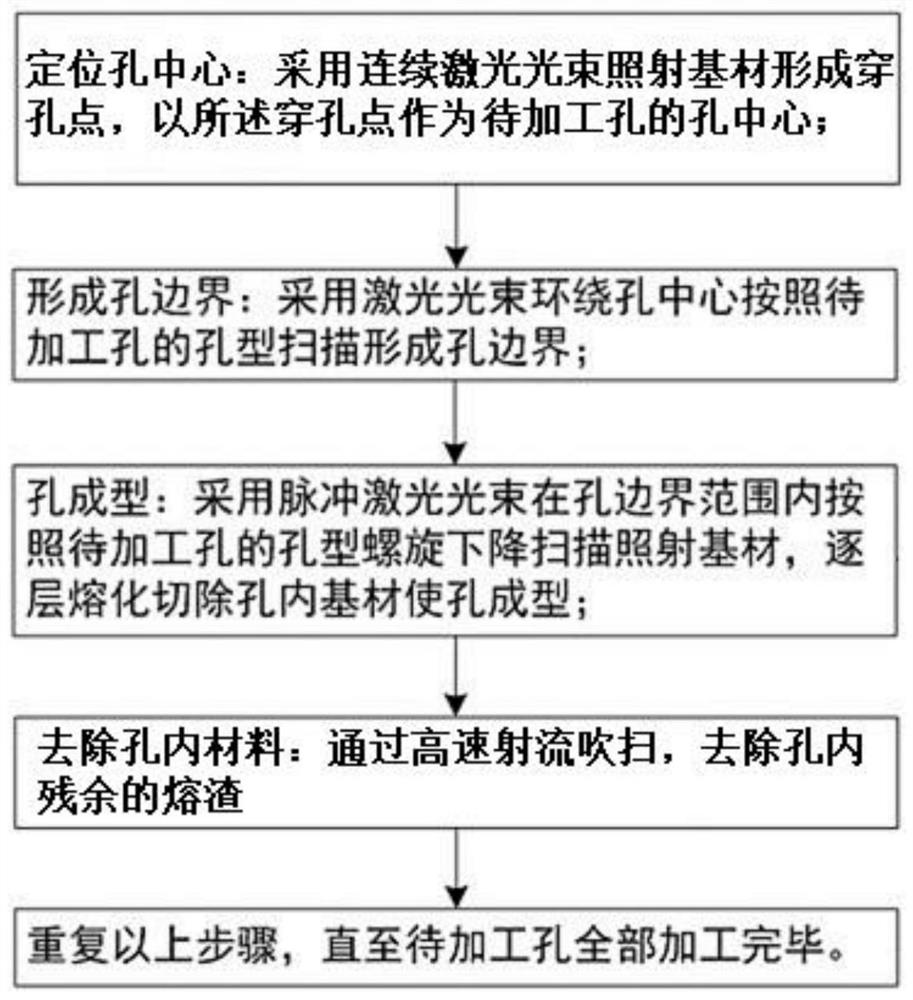

[0035] like figure 1 As shown, the laser drilling includes the following steps:

[0036] Step 1, positioning the center of the hole, including: using a continuous laser beam to irradiate the substrate to form a perforation point, and using the perforation point as the hole center of the hole to be processed;

[0037] Step 2, forming the hole boundary, including: using the laser beam to surround the center of the hole and scanning according to the hole pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com