A 3D mesh pillow wrapping method

A pillow and mesh technology, which is applied in the field of 3D mesh wrapping joint processing, can solve the problems of insufficient firmness, poor wrapping effect, and poor softness of wrapping joints, etc., and achieve the effect of good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

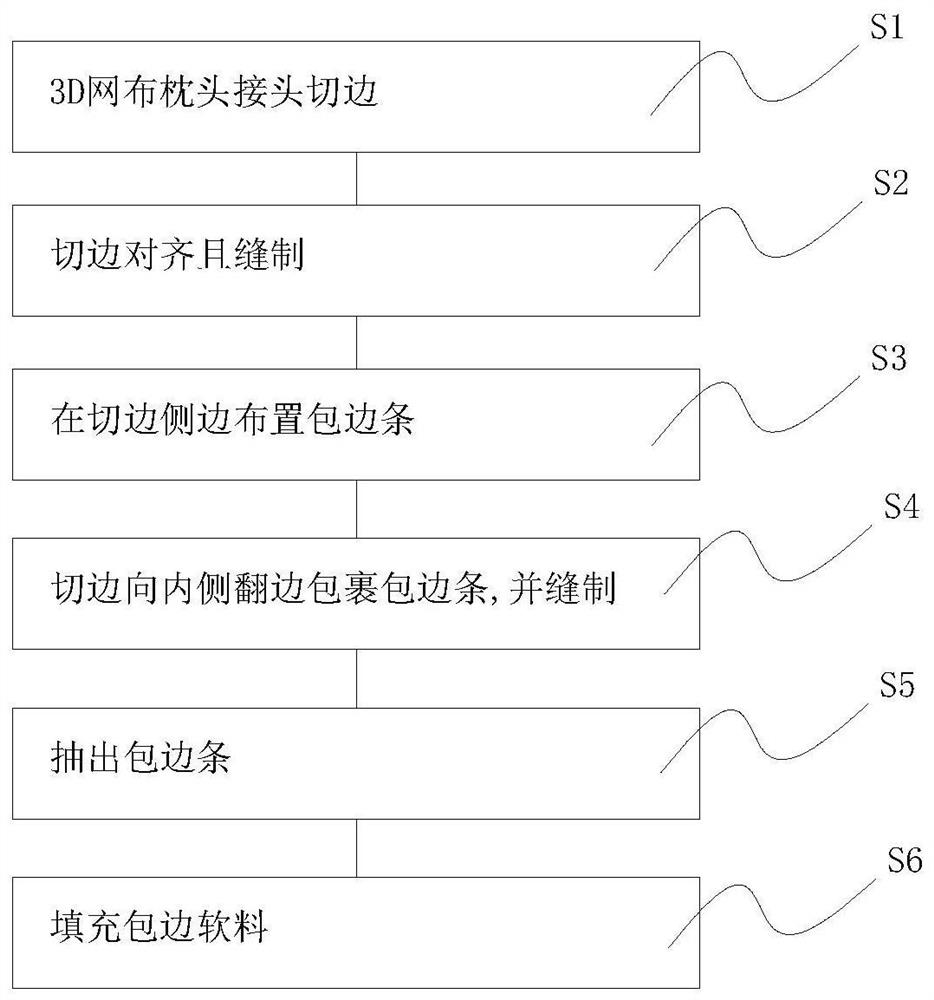

[0050] Example 1: Please refer to Figure 1-7 , a kind of 3D mesh pillow hemming method, comprises the steps:

[0051] S1, 3D mesh pillow joint trimming, trimming the pillow joints;

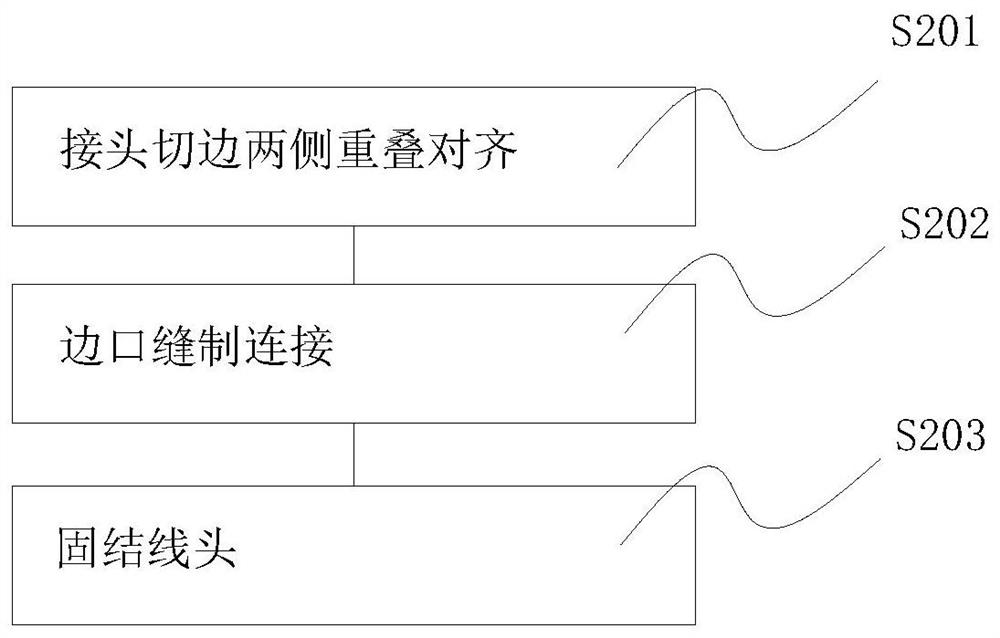

[0052] S2. Align and sew the cut edges, and align and sew the pillow joints;

[0053] S3. Arrange the wrapping strips on the trimming side, and set the wrapping strips to assist in wrapping;

[0054] S4. Flip the trimmed edge to the inside to wrap the edge strip, and sew it to form an inner edge;

[0055] S5, pull out the wrapping strip, and form a wrapping cavity at the joint of the 3D mesh pillow;

[0056] S6. Filling the soft edge wrapping material, filling the edge wrapping soft material in the edge wrapping cavity of the 3D mesh pillow.

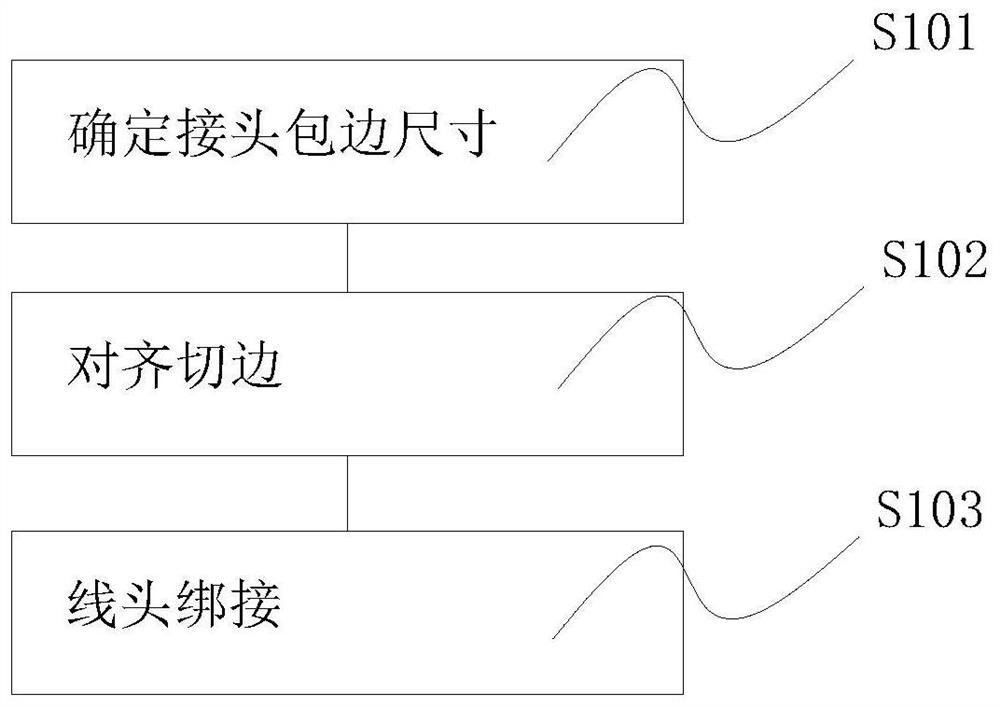

[0057] Among them, the trimming of the 3D mesh pillow joint in S1 includes the following steps:

[0058] S101. Determine the hemming size of the joint, and determine the hemming size at the joint of the 3D mesh pillow;

[0059] S102, aligning the cutt...

Embodiment 2

[0080] Example 2: Please refer to Figure 1-7 , a kind of 3D mesh pillow hemming method, comprises the steps:

[0081] S1, 3D mesh pillow joint trimming, trimming the pillow joints;

[0082] S2. Align and sew the cut edges, and align and sew the pillow joints;

[0083] S3. Arrange the wrapping strips on the trimming side, and set the wrapping strips to assist in wrapping;

[0084] S4. Flip the trimmed edge to the inside to wrap the edge strip, and sew it to form an inner edge;

[0085] S5, pull out the wrapping strip, and form a wrapping cavity at the joint of the 3D mesh pillow;

[0086] S6. Filling the soft edge wrapping material, filling the edge wrapping soft material in the edge wrapping cavity of the 3D mesh pillow.

[0087] Among them, the trimming of the 3D mesh pillow joint in S1 includes the following steps:

[0088] S101. Determine the hemming size of the joint, and determine the hemming size at the joint of the 3D mesh pillow;

[0089] S102, aligning the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com