Normally open assembly of emergency fire door

A technology for fire doors and components, applied in fire doors, door/window accessories, fastening devices for wing leaves, etc., which can solve the problems of high escape efficiency and inconvenient escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

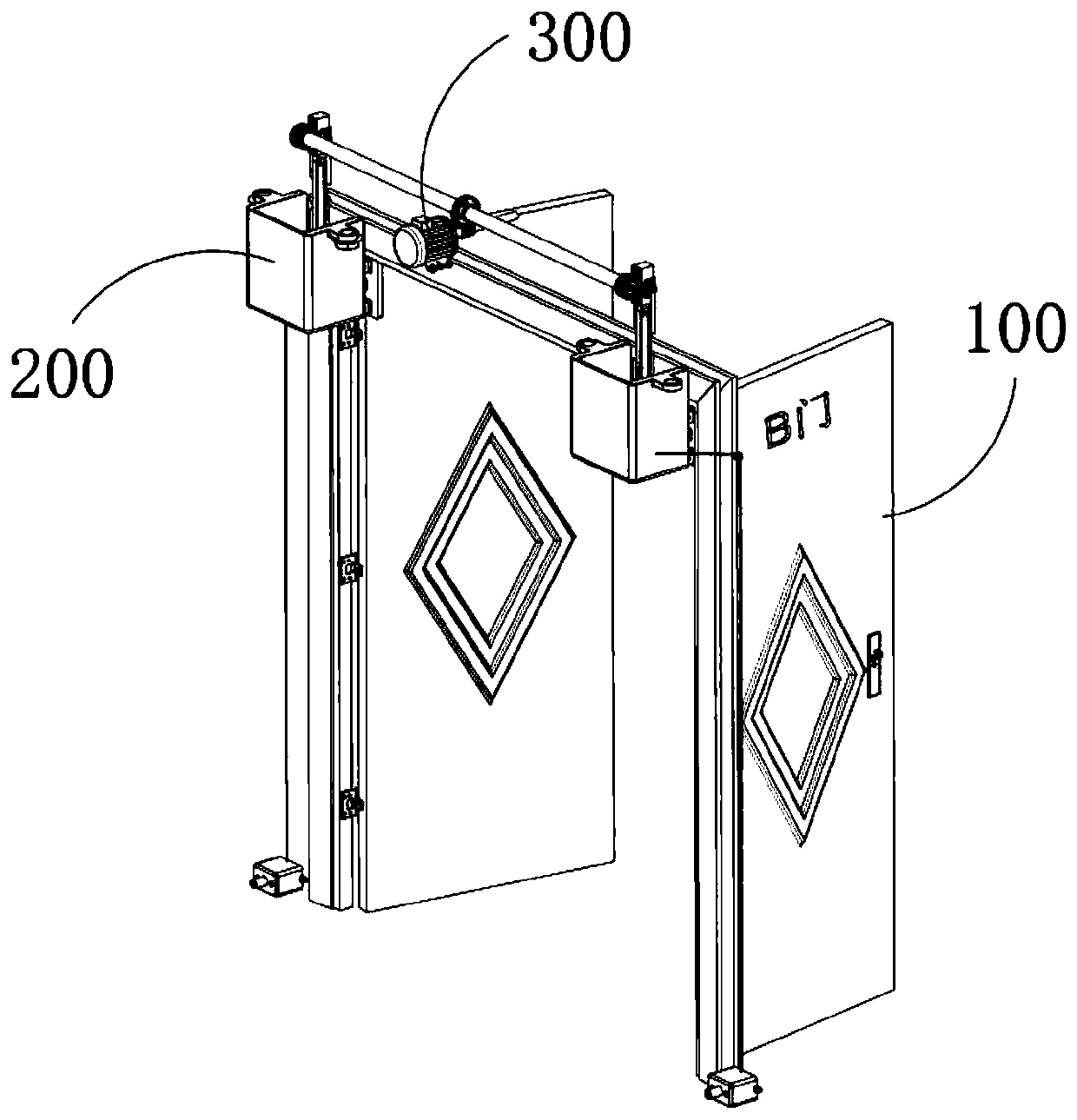

[0052] The superiority of the present invention compared with the traditional fire door is that the fire door is equipped with a fire door normally open device, which can restrict the closing of the fire door after the fire door is pushed open, and keep the open state even after the fire door is pushed open , in the event of a fire, the first person only needs to push the fire door, and the subsequent evacuees can quickly pass through, and the escape efficiency is higher. At the same time, after the fire is extinguished, the staff only need to kick the reset closing mechanism to make the fire door Automatic closing, the closing process is simple.

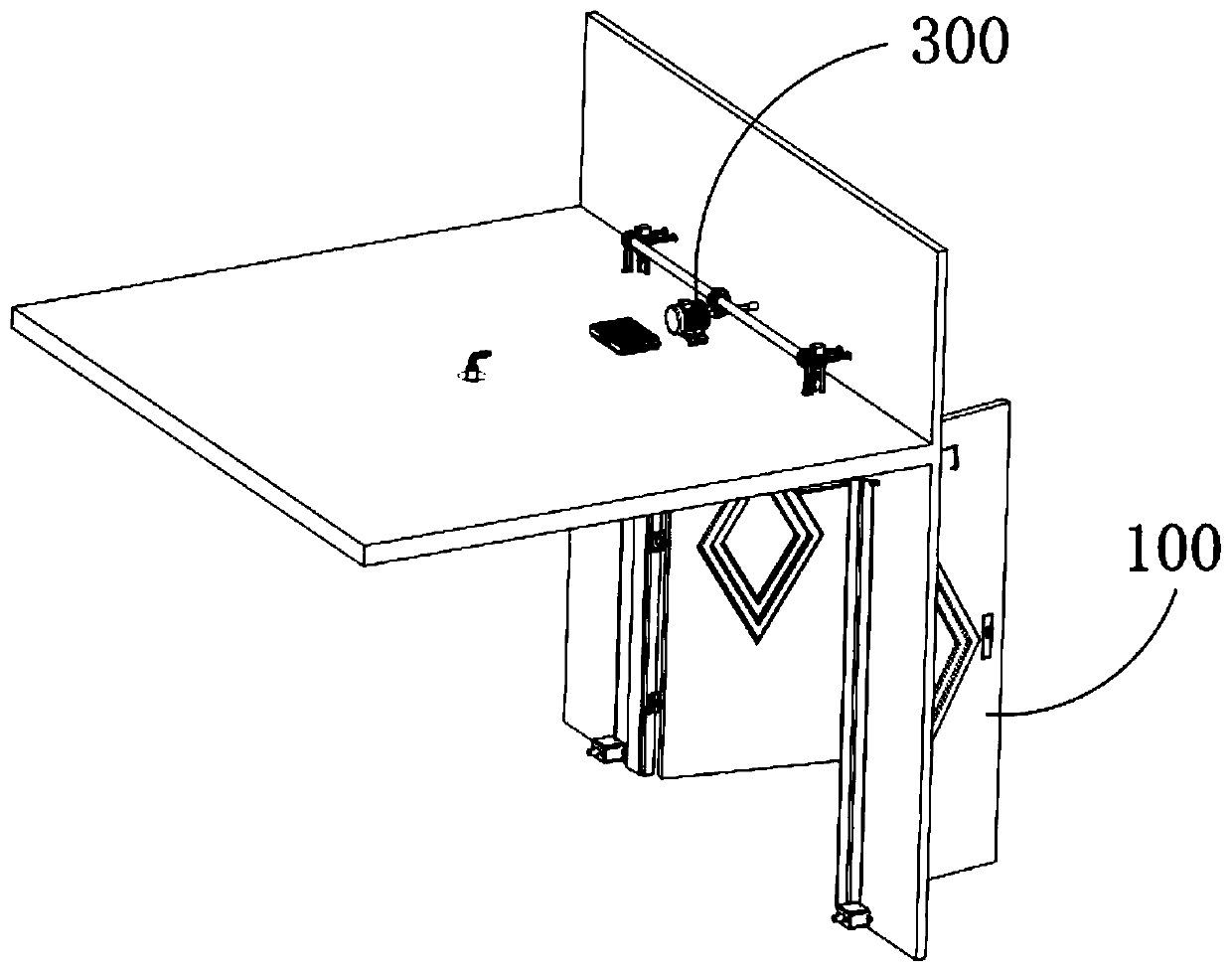

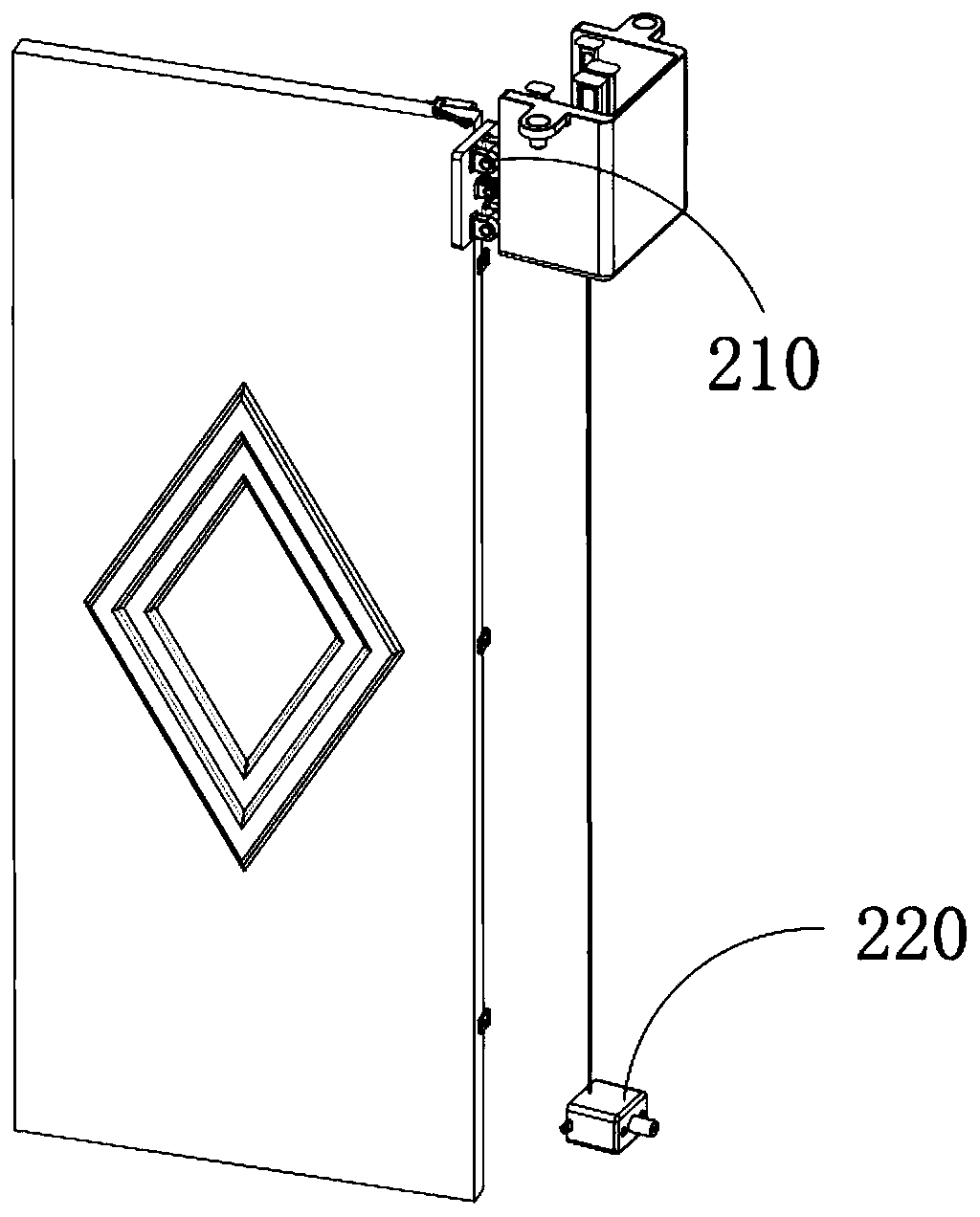

[0053] The equipment used to keep the fire door normally open after being pushed open includes a fire door normally open device 200 used to limit the closing of the fire door body 100 during the opening process, and is used to trigger the fire door normally open device 200 The auxiliary device 300 that assists it during operation; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com