Connecting structure of electromagnetic hot melting pipe fitting

A connection structure, electromagnetic hot melting technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problem of inability to use ordinary plastic pipes, achieve light weight, improve hot melt quality, overall weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

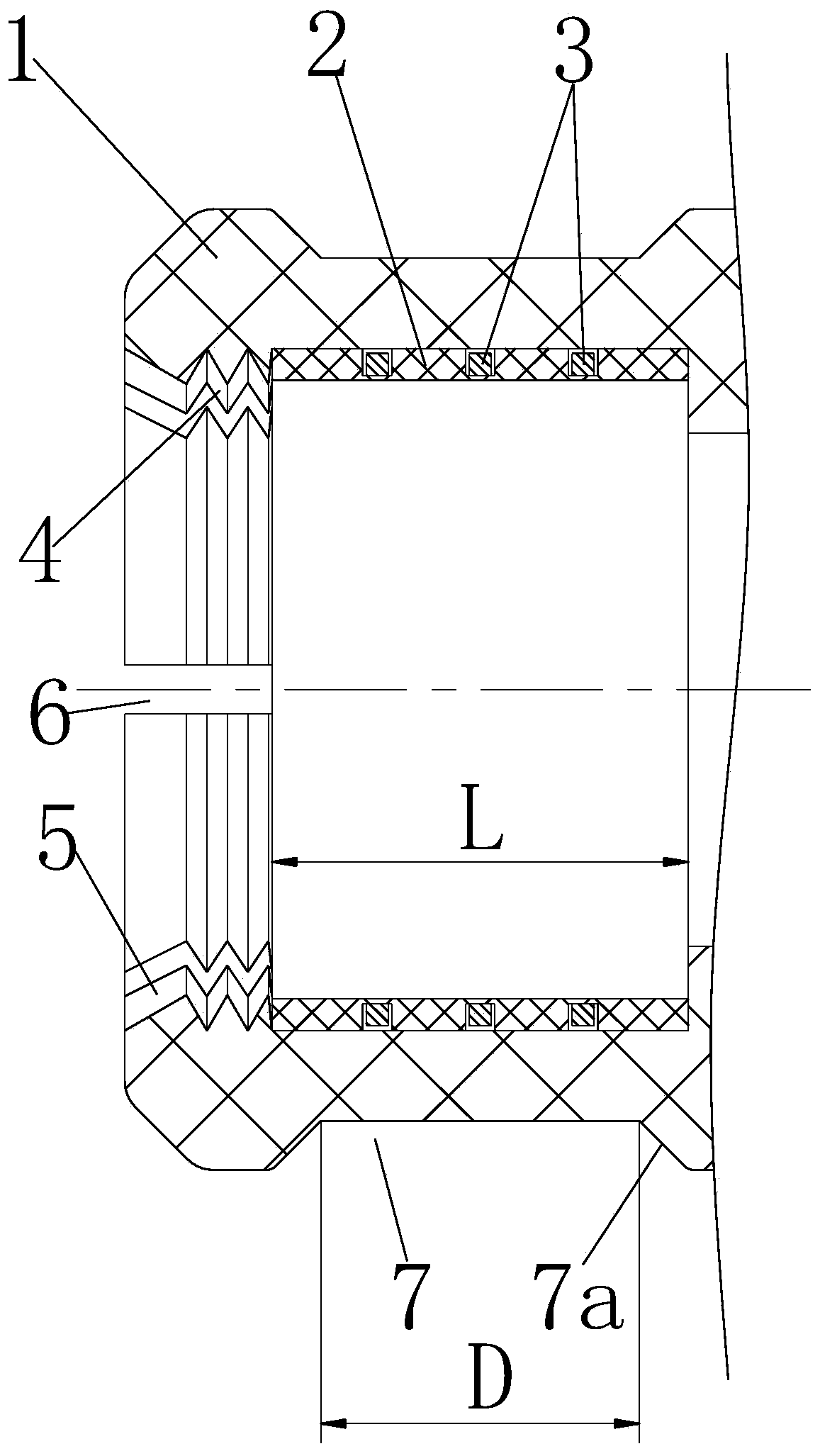

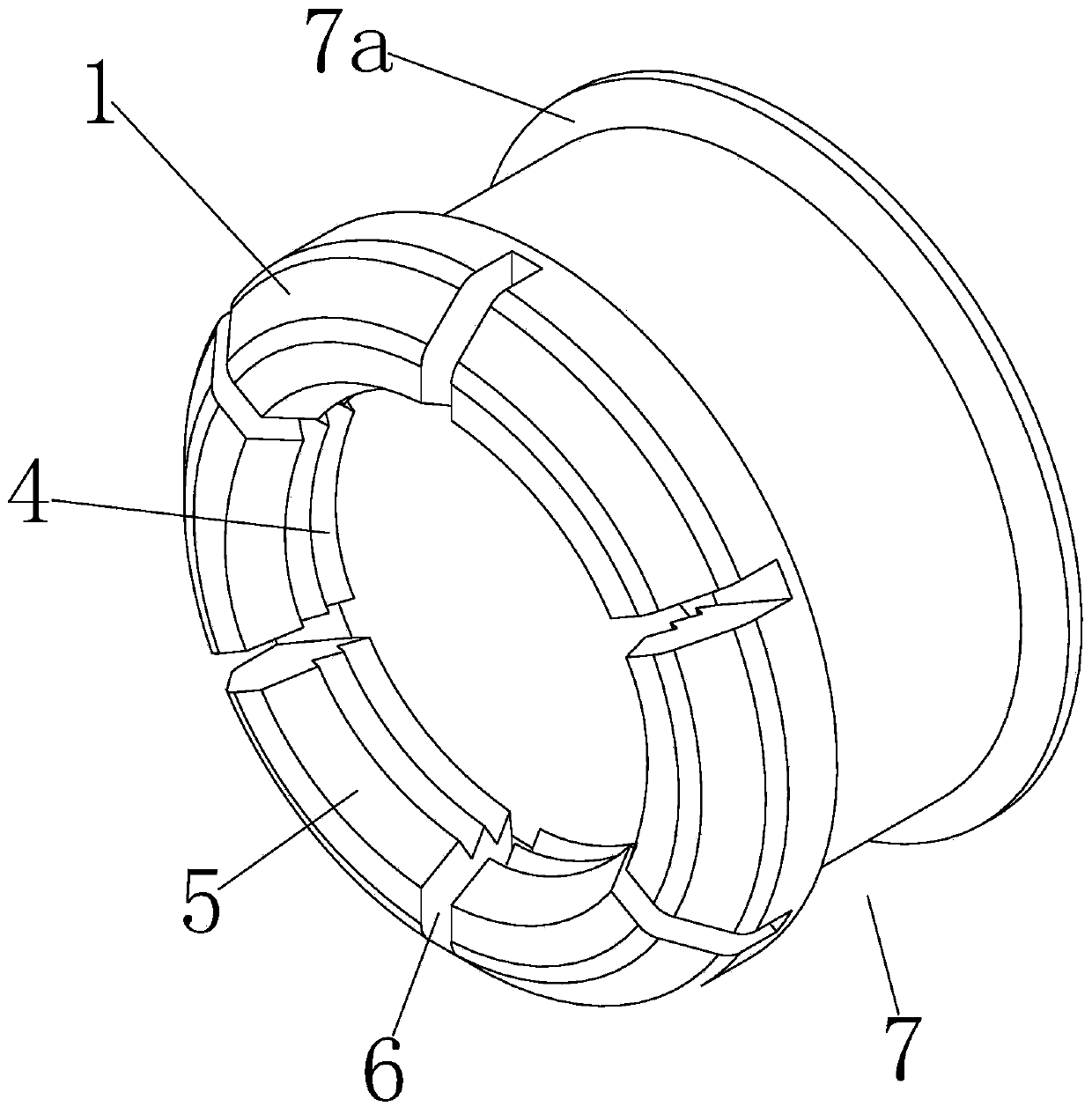

[0031] This embodiment provides a connection structure of electromagnetic hot-melt pipe fittings, including a pipe fitting body 1, a hot-melt inner sleeve 2 is embedded on the inner wall of the socket of the pipe fitting body 1, and the inner hot-melt inner sleeve 2 is axially spaced Several electromagnetic induction heat generating support rings 3 are embedded, and the electromagnetic induction heat generating support rings 3 are coaxially arranged with the hot-melt inner sleeve 2 . By embedding a hot-melt inner sleeve 2 on the inner wall of the socket of the pipe fitting body 1, and inserting several electromagnetic induction heat-generating support rings 3 in the inner hot-melt sleeve 2 along the axial interval, the electric welding can be made through the electromagnetic welding fixture. The magnetic induction heat-generating support ring 3 generates heat to perform hot-melt connection between the hot-melt inner sleeve 2 and the pipe to be connected. The structure is simple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com