Method and system for determining equipment maintenance interval time and electronic equipment

A maintenance interval and equipment technology, applied in the direction of instruments, etc., can solve the problems of waste of manpower and financial resources, failure to effectively ensure the normal operation of equipment, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

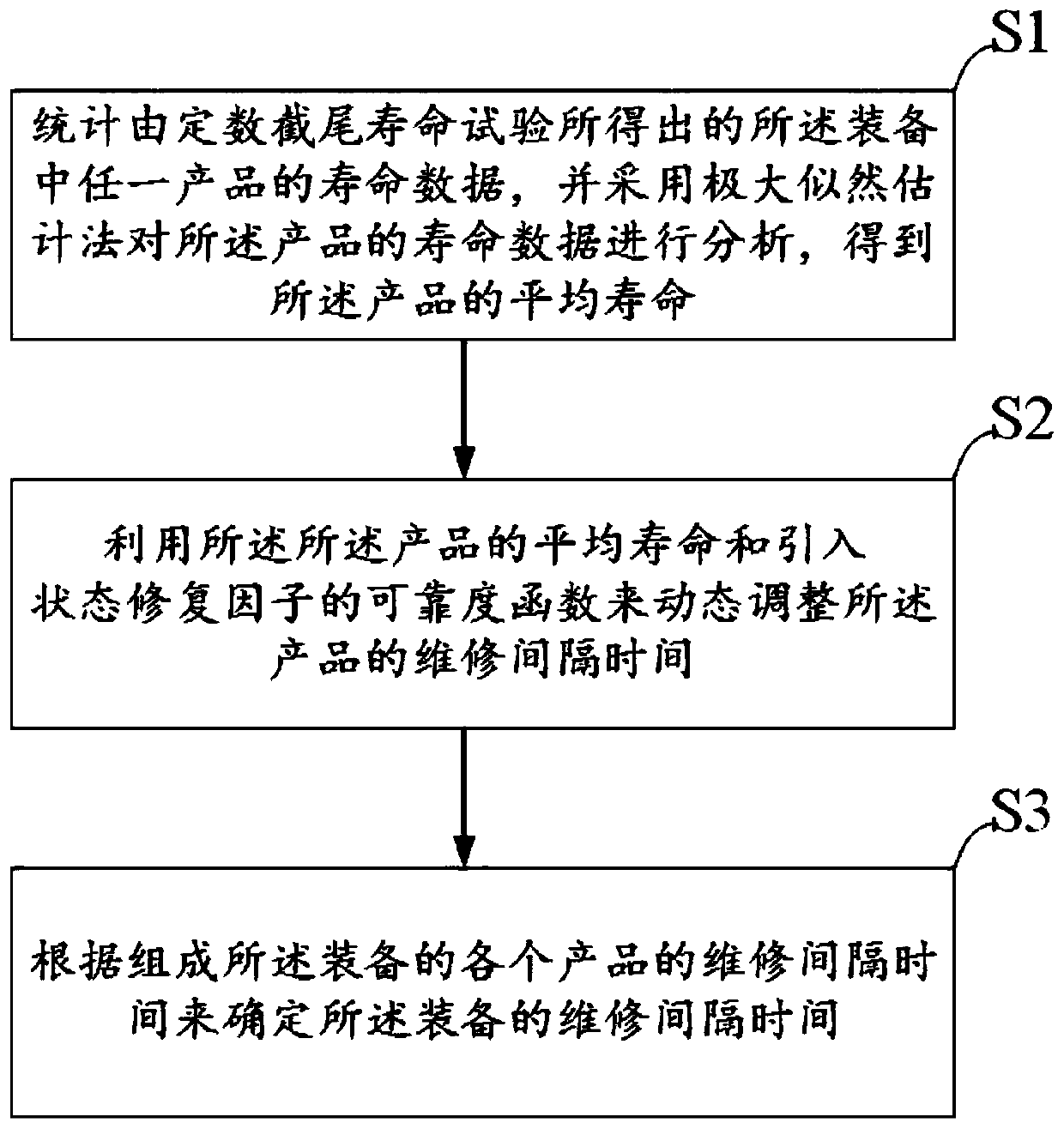

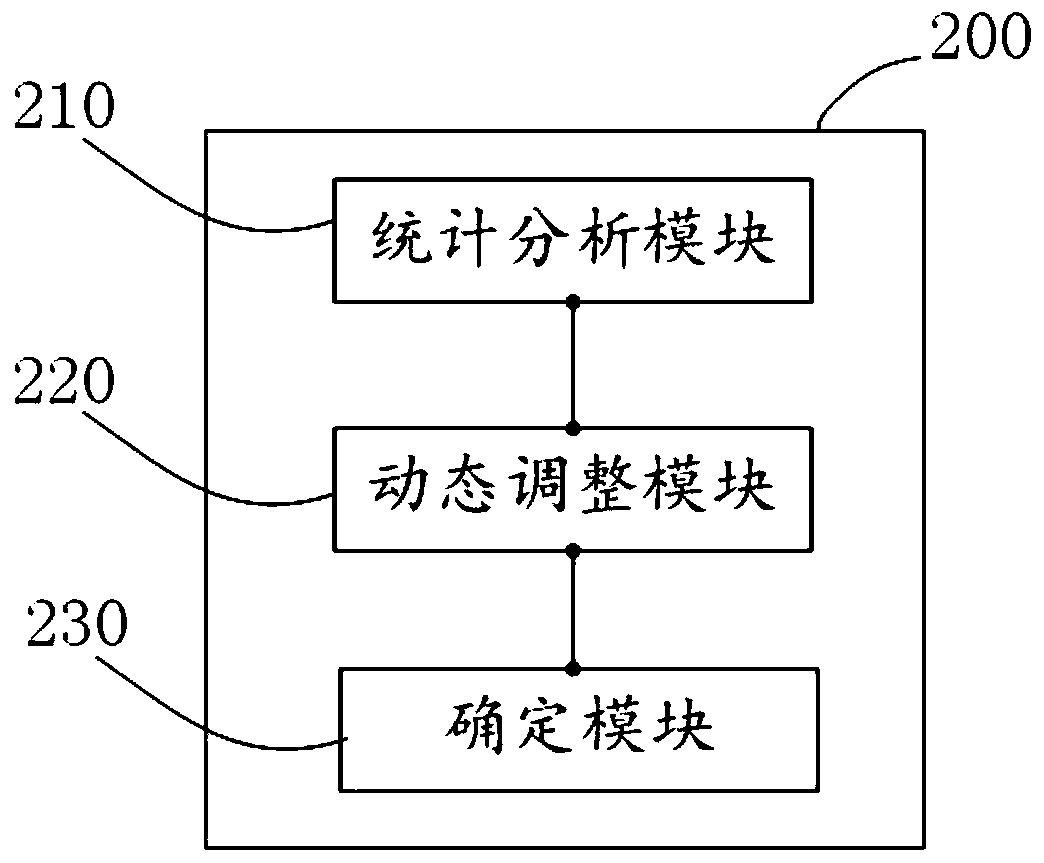

[0110] A method for determining the maintenance interval of equipment in this embodiment, such as figure 1 described, including the following steps:

[0111] S1, counting the life data of any product in the equipment obtained by the fixed-number censored life test, and using the maximum likelihood estimation method to analyze the life data of the product to obtain the average life of the product;

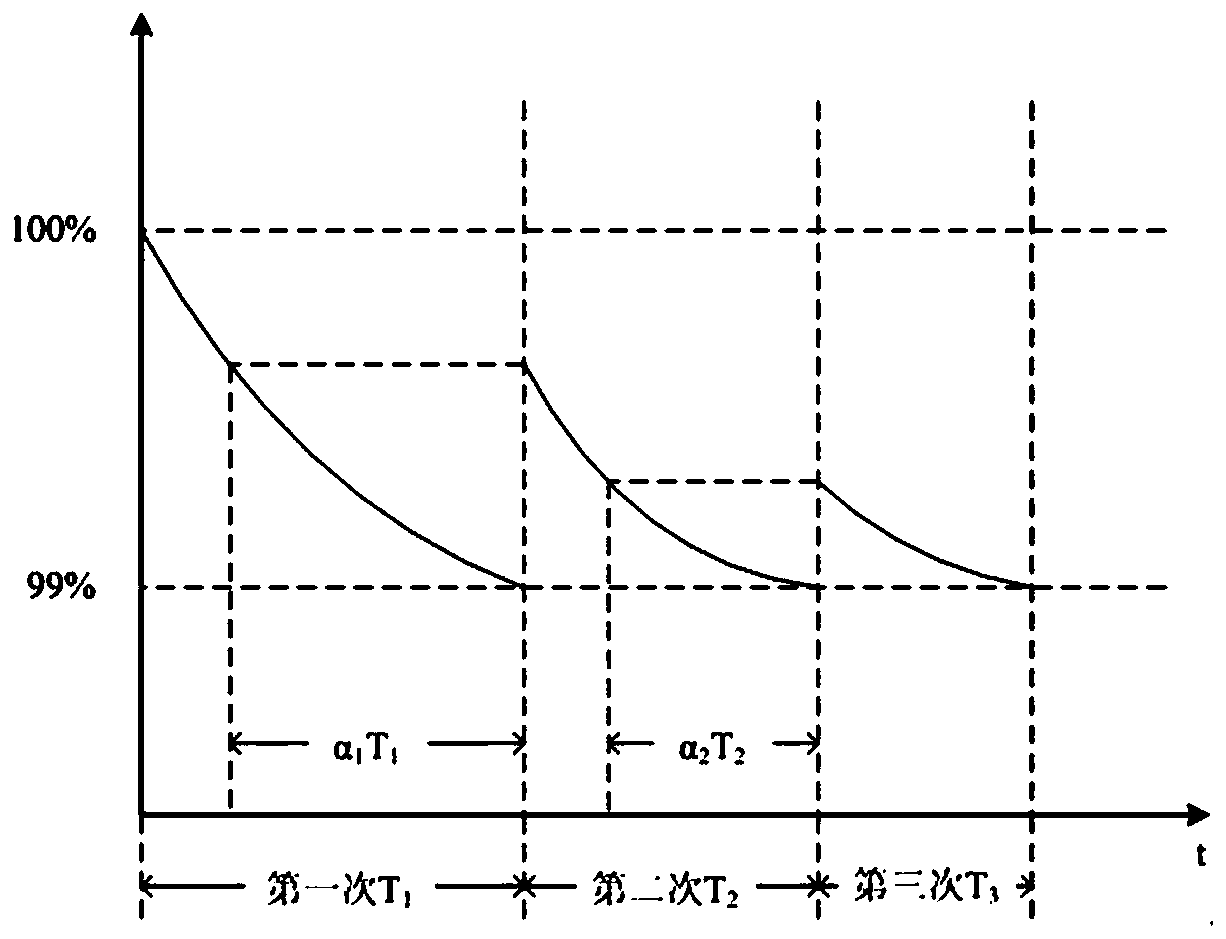

[0112] S2. Dynamically adjust the maintenance interval of the product by using the average life of the product and the reliability function introducing the state repair factor;

[0113] S3. Determine the maintenance interval time of the equipment according to the maintenance interval time of each product.

[0114] Using the maximum likelihood estimation method to analyze the life data of any product in the equipment obtained from the fixed-number censored life test, the average life of the product is obtained, and then according to the average life of the product and the reliabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com