Hoisting operation experience device of large shipyard

A shipyard, large-scale technology, applied in the field of lifting operation experience devices, can solve problems such as lifting injury accidents, and achieve the effect of reducing dangerous accidents and enhancing safety knowledge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

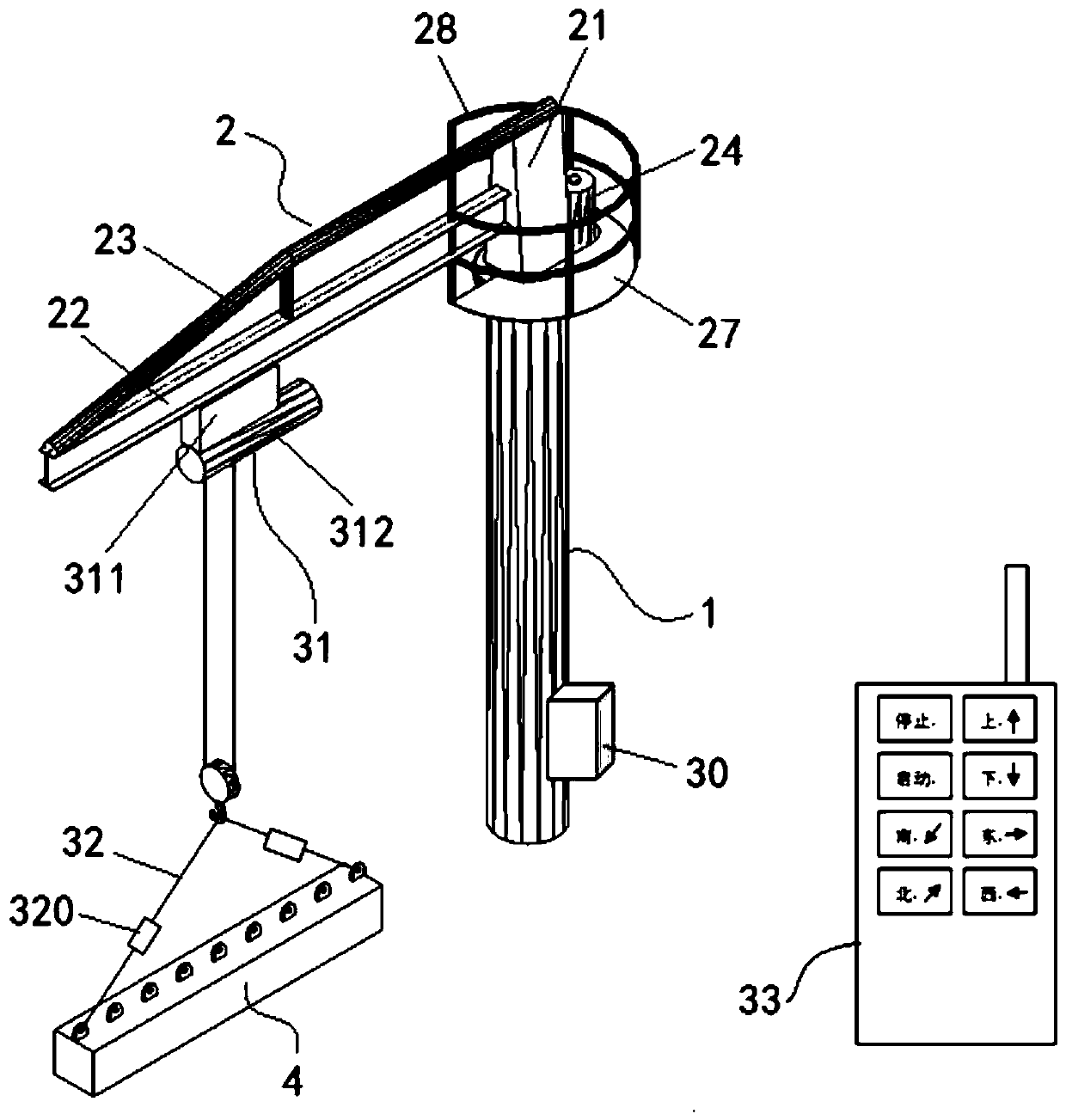

[0018] see Figure 1 to Figure 4 , the large-scale shipyard lifting operation experience device of the present invention includes a cantilever crane support mechanism 1, a lifting cantilever beam 2, a lifting device and a heavy object 4.

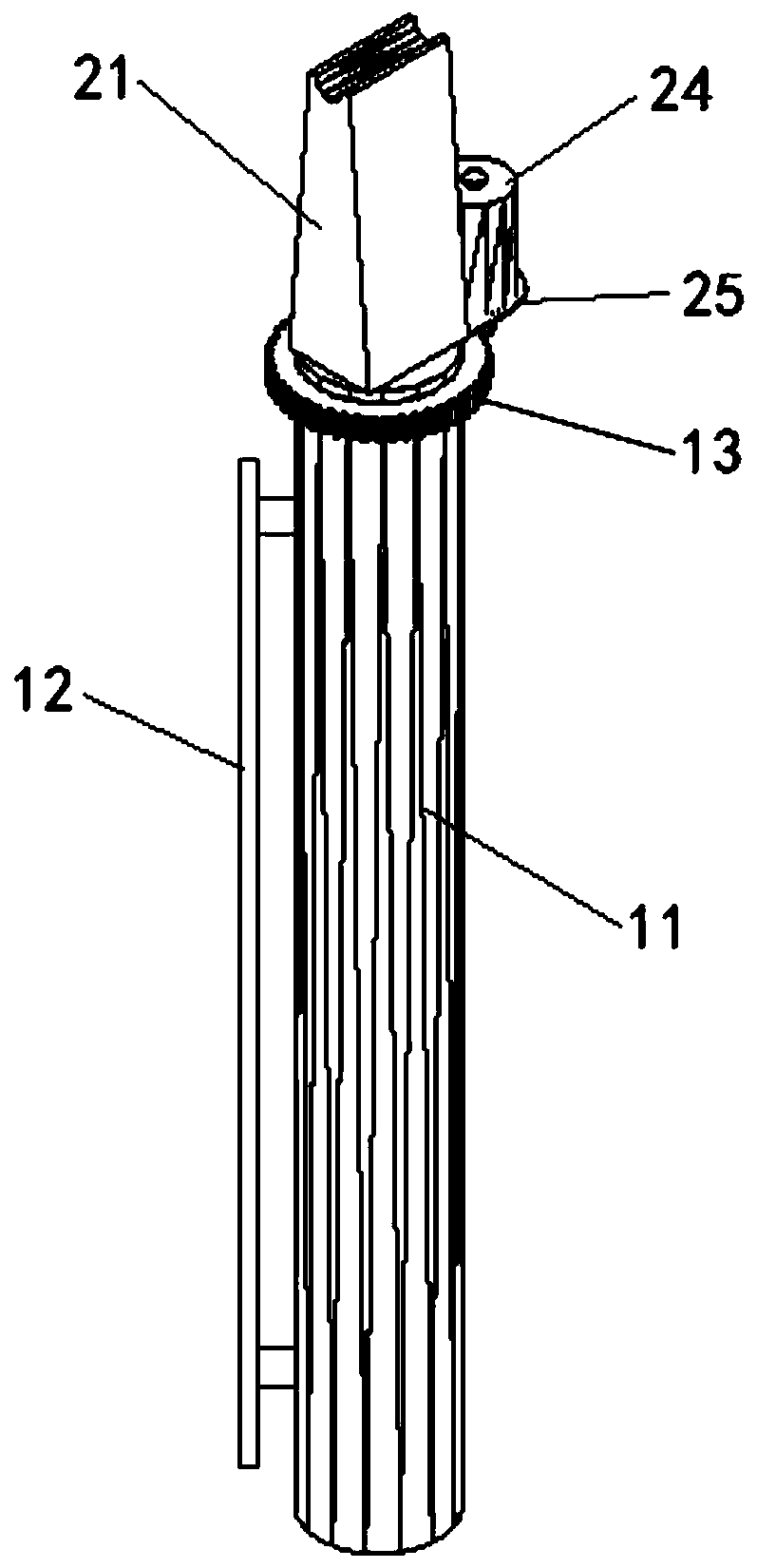

[0019] Cantilever crane supporting mechanism 1 comprises column 11, straight ladder 12 and bull gear 13; Wherein, column 11 is a steel cylinder and is fixed on the ground; Straight ladder 12 is installed on one side of column 11; The outer diameter of the column 11 is fixed on the top surface of the column 11 .

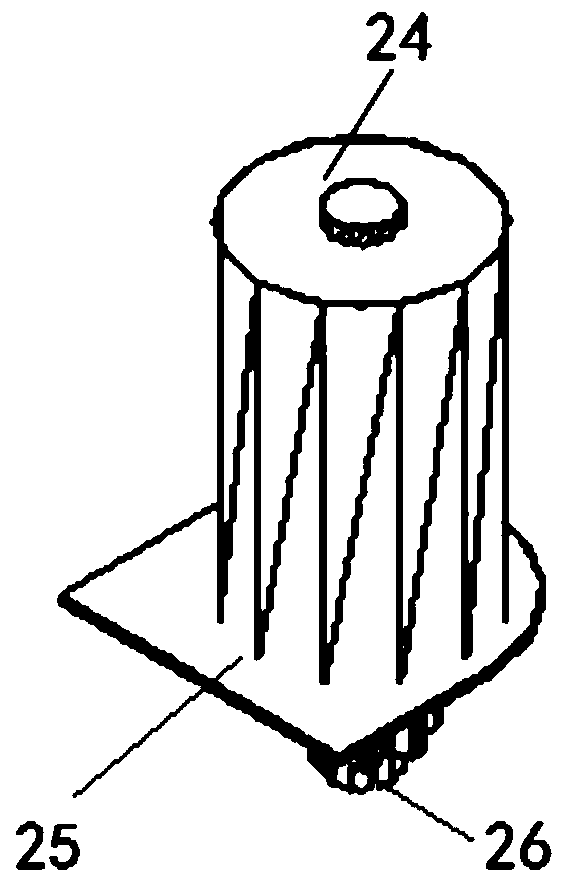

[0020] Lifting cantilever beam 2 comprises swivel seat 21, crossbeam 22, pull bar 23, gear box 24 and maintenance platform 27; On the top surface, the shaft on the large gear 13 is stretched into the rotating base 21 to be connected with the bearing; Between the surface and the top surface of the other end of the beam 22; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com