Metal parts stamping system

A technology for metal fittings to be stamped, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of inaccurate stamping dimensions and low quality of metal fittings, and achieve the effect of improving quality and avoiding serious wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

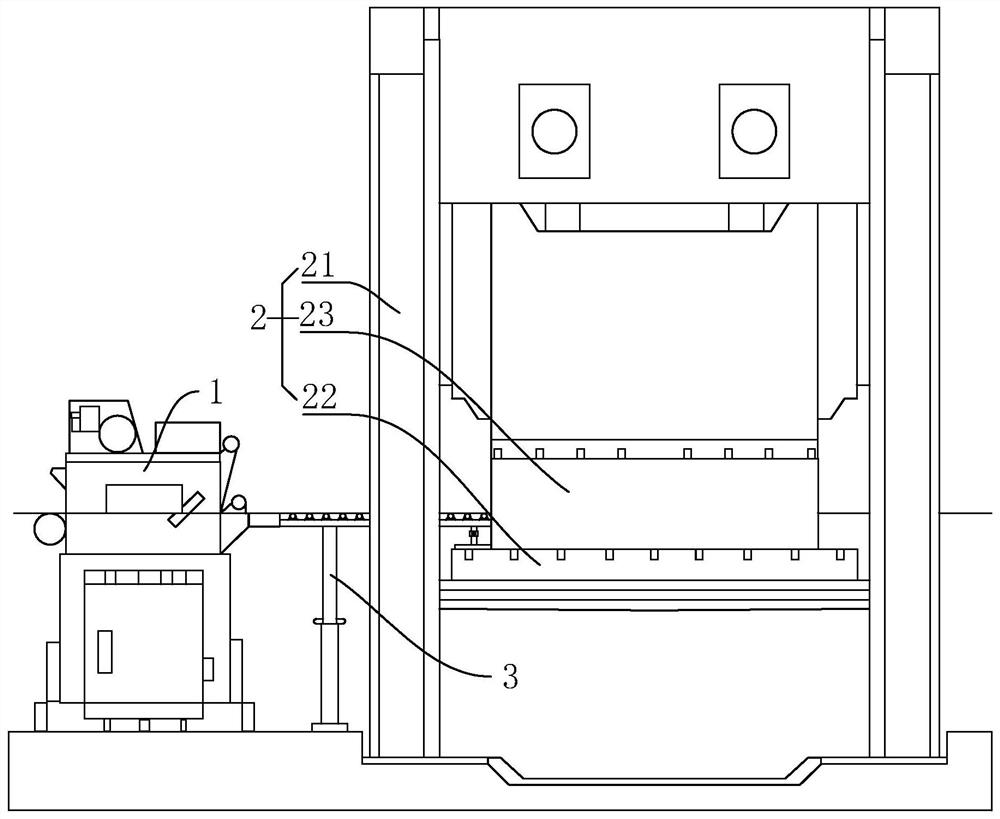

[0038] refer to figure 1 , is a stamping system for metal fittings disclosed in the present invention, comprising: a leveling mechanism 1, a stamping mechanism 2 and a supporting mechanism 3; The side near the leveling mechanism 1 is provided with a steel strip inlet, the support mechanism 3 is arranged on the ground and / or on the stamping mechanism 2, one end of the support mechanism 3 is connected to the output end of the leveling mechanism 1, and the other end of the support mechanism 3 Connecting with the input end of the stamping die 23, the top surface of the support mechanism 3 supports the steel strip to be stamped so as to keep the strip steel to be stamped in a horizontal state.

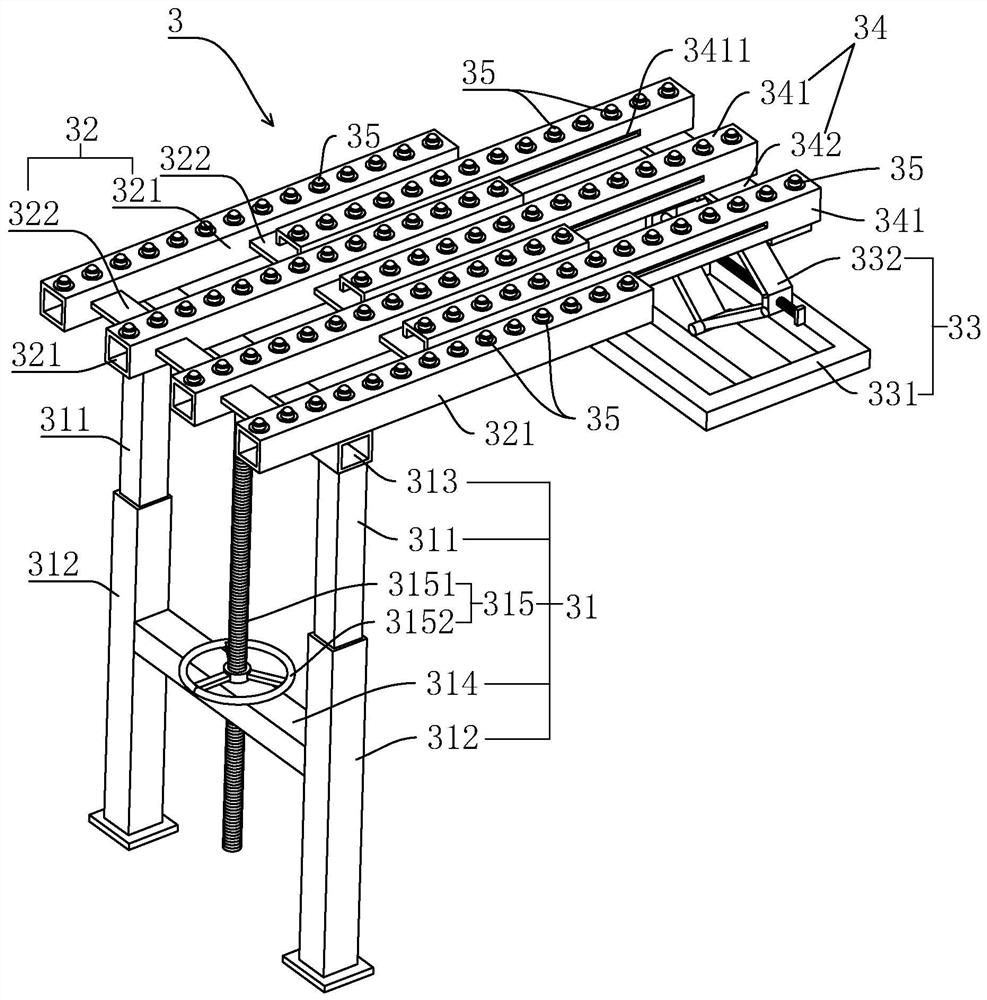

[0039] combine figure 1 and figure 2 As shown, the support mechanism 3 includes: a first support portion 31, a first horizontal frame 32, a second support portion 33, a second horizontal frame 34 and a rolling support 35, and the rolling support 35 is located on the first horizontal fram...

Embodiment 2

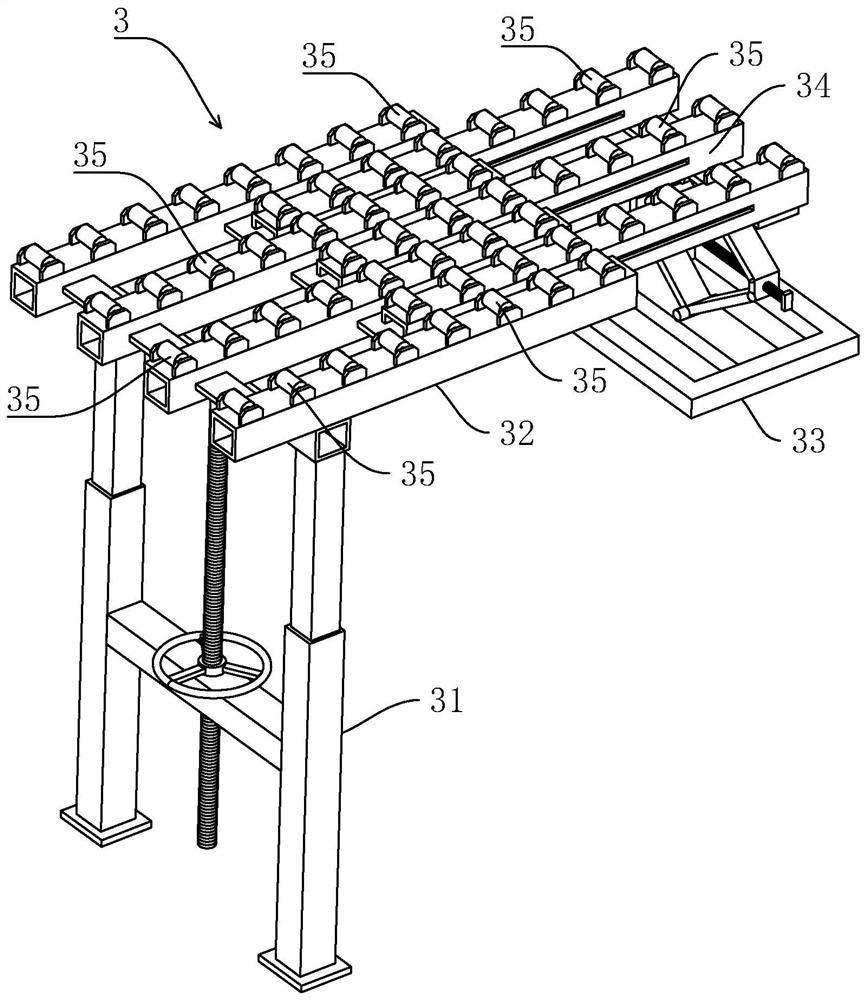

[0052] refer to figure 1 and image 3 , is a stamping system for metal fittings disclosed in the present invention. The difference from Embodiment 1 is that the rolling support 35 is specifically an idler, and the idler is rotatably assembled on the upper surfaces of the first horizontal frame 32 and the second horizontal frame 34 , the rollers are arranged horizontally, and the layout direction of the rollers is perpendicular to the conveying direction of the strip to be stamped. The rollers can be purchased directly from the market, which is convenient to purchase, low in cost, and simple to install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com