Discharging device applied to manufacturing of sand core and realizing convenient control on discharging amount

A stripping device and material quantity technology, which is applied to the cleaning/processing machinery of casting materials, manufacturing tools, parts of molding machines, etc., can solve the problems of waste of resources, prone to judgment errors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

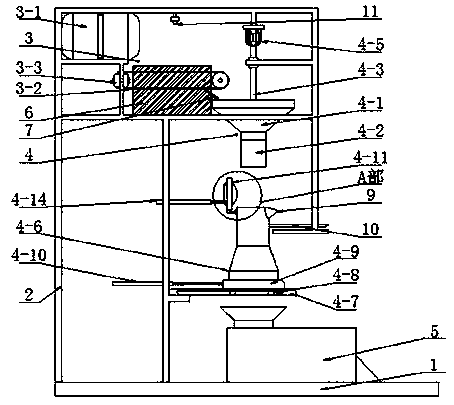

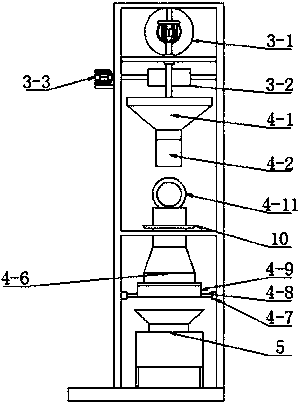

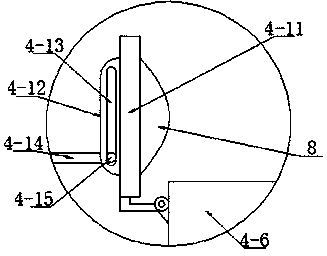

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] see as Figure 1-Figure 5 As shown, this specific embodiment includes a base 1, a bracket 2, a core sand preparation component 3, a quantitative blanking component 4, and a molding machine 5, wherein the base 1 is welded with a bracket 2, and the upper left end of the bracket 2 is fixedly provided with a The core sand preparation component 3, the quantitative blanking component 4 is fixedly arranged on the right end of the bracket 2, and the quantitative blanking component 4 is arranged under the side of the core sand preparation component 3, and the quantitative blanking component 4 is arranged through the core sand preparation component 3, A molding machine 5 is riveted and fixed on the base 1, and the molding machine 5 is arranged on the right side of the support 2, and the feed port of the molding machine 5 is connected with the discharge port of the quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com