Method and system for preheating ingredients of prebaked anode paste for electrolytic aluminium

A pre-baked anode and pre-heating technology, which is applied in the field of proportioning and electrolytic aluminum heating, can solve the problems of low production efficiency and large proportion error, and achieve the effects of improving production efficiency, preventing material blocking, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

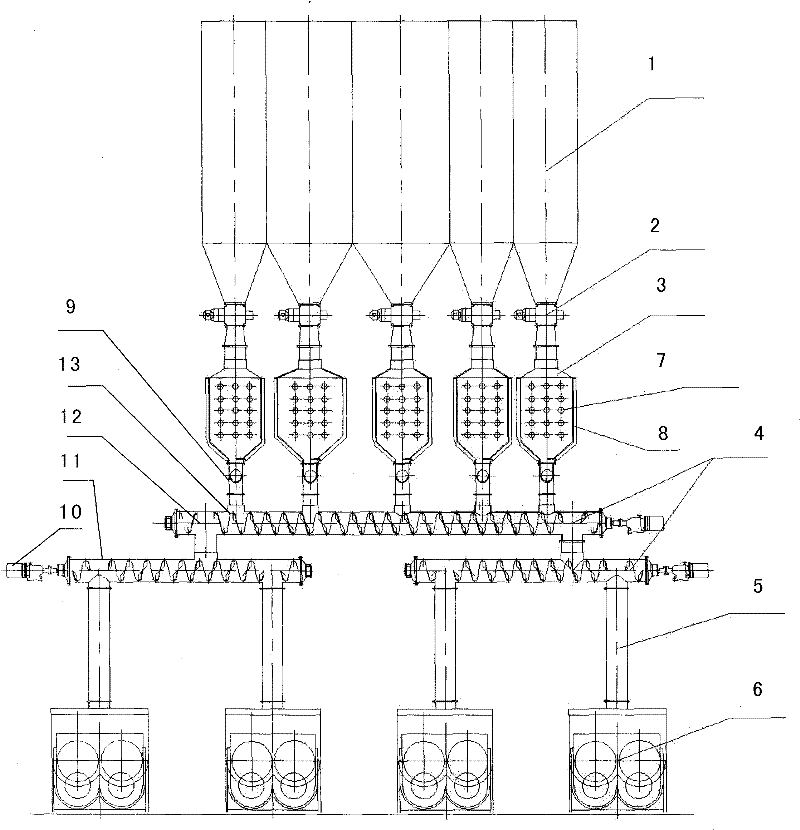

[0027] Such as figure 1 Shown: a method of preheating and compounding prebaked anode paste for electrolytic aluminum, adopting the method of heating material proportioning, and the steps are as follows:

[0028] a. Store raw materials with different particle sizes in different preheating silos 3 through fixed storage silos;

[0029] b. There is a heating device in the pre-heating bin 3, which pre-heats the raw materials to ensure the temperature of the materials at about 180°C;

[0030] c. Each heating bin 3 is equipped with a metering device, and the discharge volume is controlled by subtraction measurement, so that the feeding accuracy is within 5‰; the raw materials in each heating bin 3 can be discharged 3 to 4 times, after When the metering device detects that the discharge volume is less than the set value, the star-shaped discharge valve 2 on the upper part of the heating bin 3 is activated, and the material is discharged into it until the required set value is reached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com