Marine hydrodynamic force energy-saving combination type conduit hydrofoil

A combined, hydrodynamic technology, applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as weakening effects, achieve the effect of reducing main engine power and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

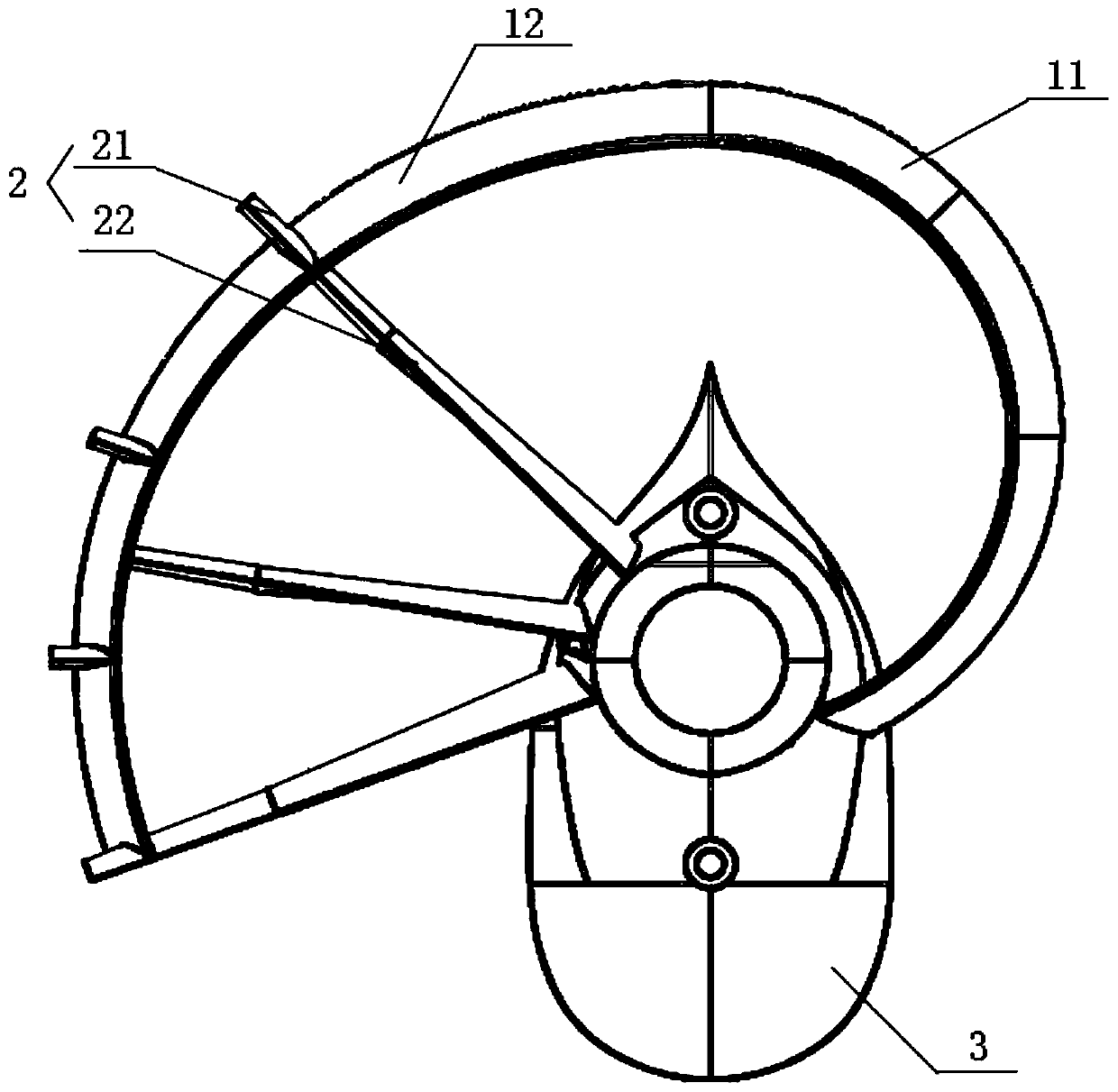

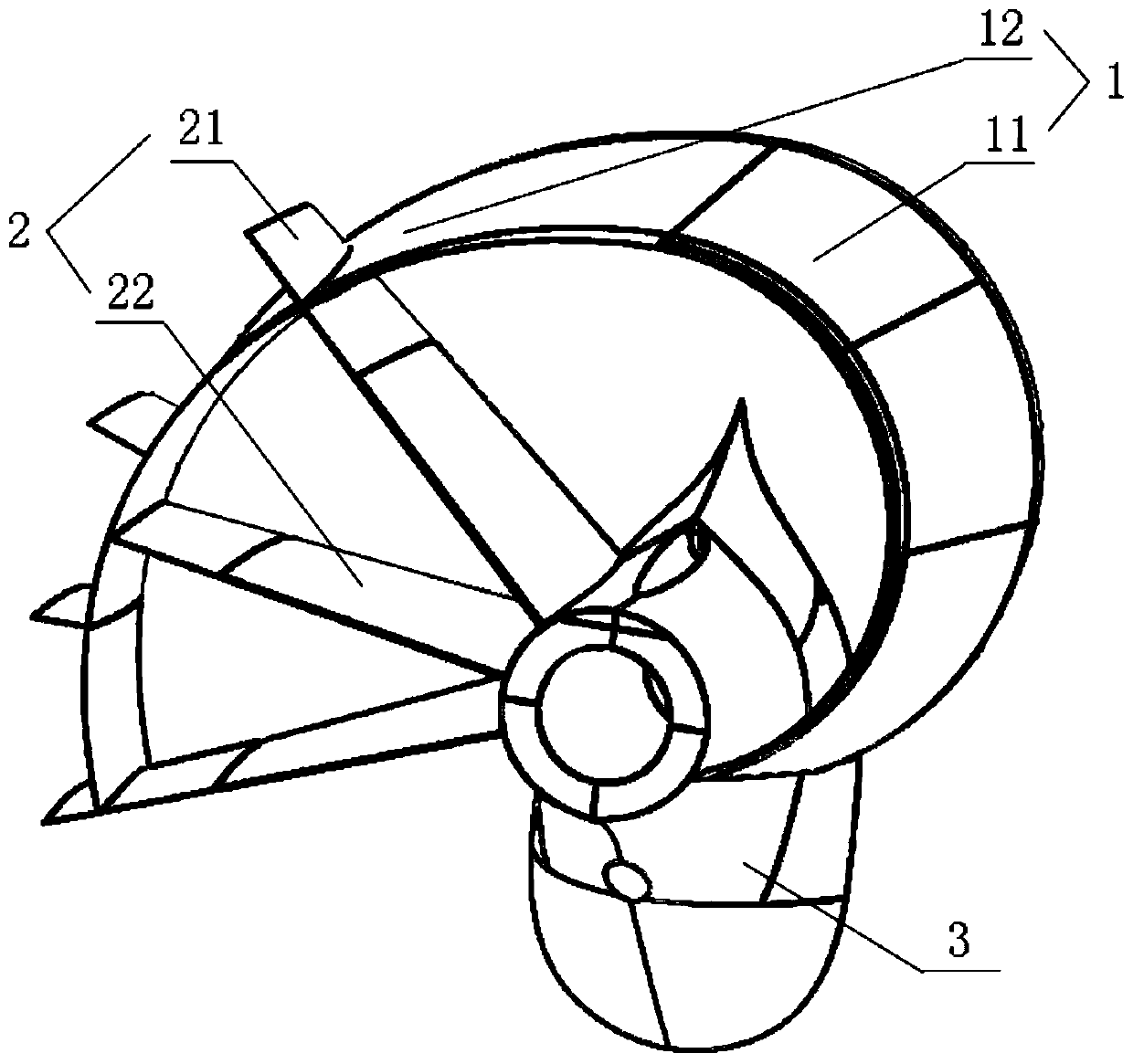

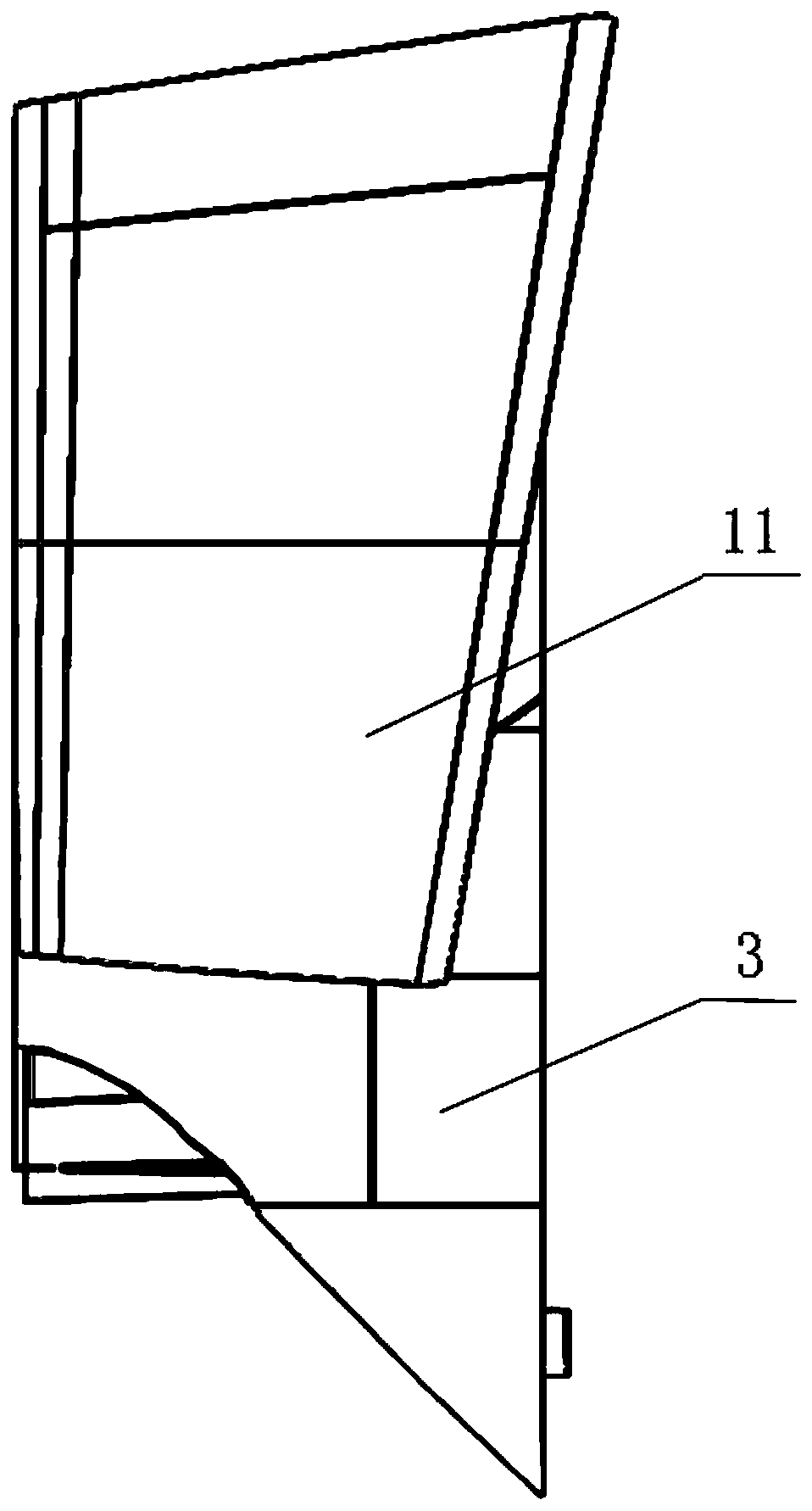

[0034] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following examples are combined with the appended figure 1 to attach Figure 11 A marine hydrodynamic energy-saving combined ducted hydrofoil provided by the present invention will be described in detail.

[0035] In this embodiment, the ship's hydrodynamic energy-saving combined ducted hydrofoil mainly includes a duct 1, a non-full circular annular duct 11, a non-complete elliptical annular duct 12, hydrofoils 2, duct outer hydrofoils 21, duct inner hydrofoils 22. Hull 3.

[0036] The combined ducted hydrofoil is arranged in front of the propeller and at the tail of the ship close to the propeller. The combined ducted hydrofoil includes a duct 1 and several hydrofoils 2, wherein the duct 1 is composed of a non-complete circular annular duct 11 and an incomplete elliptical annular duct 12 , and the incomplete elliptical ring conduit 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com