A kind of treatment method of dry desulfurization ash

A technology for dry desulfurization ash and a treatment method, which is applied in the field of resource utilization of dry desulfurization ash, can solve the problems of high oxidation cost, uneven heating, and low possibility of dry desulfurization ash, so as to shorten the oxidation time and reduce the Oxidation cost, effect of wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

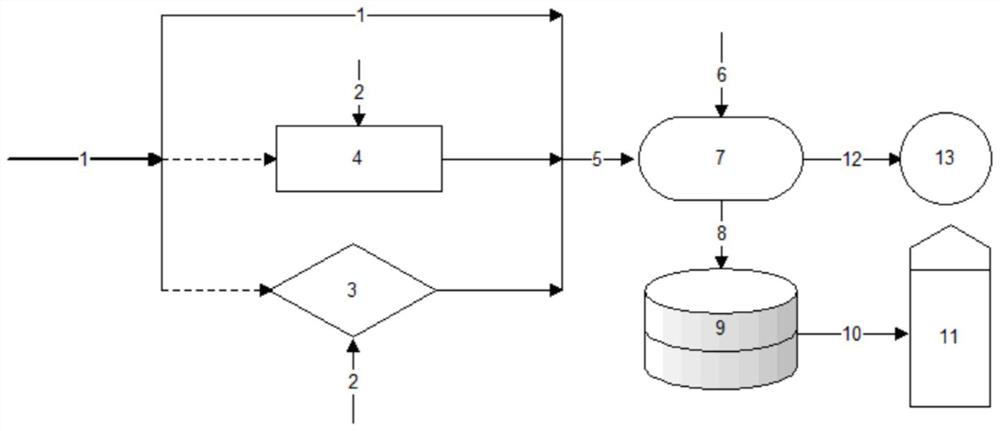

[0061] The process flow chart of the treatment method of the dry desulfurization ash provided by Embodiment 1 of the present invention can be found figure 1 As shown, among them, 1 is high-temperature hot air, 2 is cold air at normal temperature, 3 is an oxidation hot air mixing preparation device, 4 is a heat exchanger, 5 is oxidation hot air, 6 is dry desulfurization ash to be treated, and 7 is a fluidized bed / Rotary kiln oxidation device, 8 is the high-temperature desulfurization ash after oxidation, 9 is the cooling device, 10 is the oxidized product after cooling, 11 is the finished product storage bin, 12 is the hot air after oxidation, and 13 is the hot air recycling device in the factory.

[0062] Specific steps are as follows:

[0063] (1) High-temperature hot air (1) comes from the tertiary air of a new cement kiln with an oxygen content of 21% and a temperature of 900°C; the high-temperature hot air (1) and normal-temperature cold air (2) are placed in The oxidati...

Embodiment 2

[0071] According to the process flow diagram of the treatment method of the dry desulfurization ash provided in Example 1; the specific steps are as follows:

[0072] (1) High-temperature hot air (1) comes from the high-temperature section of the new cement kiln kiln head cooling air (generally used for waste heat power generation), its oxygen content is 21%, and the temperature is 500 ° C; the high-temperature hot air (1) does not need to be treated directly Oxidation hot air (5).

[0073] (2) The oxidation hot air (5) and the dry desulfurization ash (6) to be treated are entered into the rotary kiln oxidation device (7); the processing capacity of the dry desulfurization ash (6) to be treated is 6 ton / hour, the flow rate of oxidation hot air (5) is 20000m 3 / h; the internal temperature of the rotary kiln oxidation device (7) is 450°C, and the residence time is 1min; then it is collected by high-temperature cyclone dust removal, and the efficiency exceeds 80%, and the high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com