Pretreatment method for landslide dam impervious wall grooving construction

A technology for trough construction and anti-seepage wall, applied in blasting and other directions, can solve the problems of high cost of demolition, difficult construction of anti-seepage wall, overhead phenomenon, etc., to achieve good construction quality, reduce the risk of trough collapse, and prevent the hole inclination exceeding the standard. the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

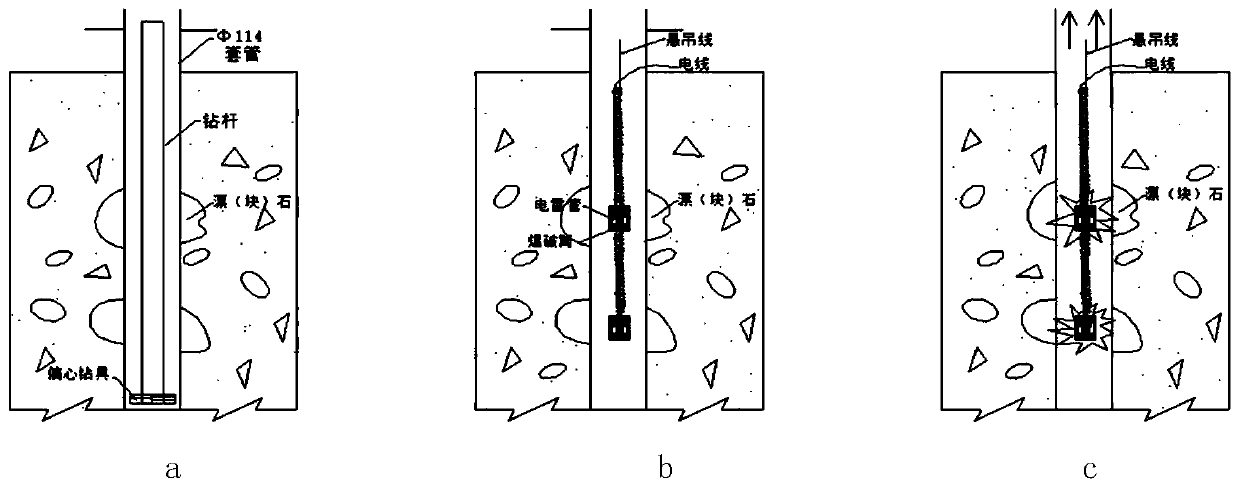

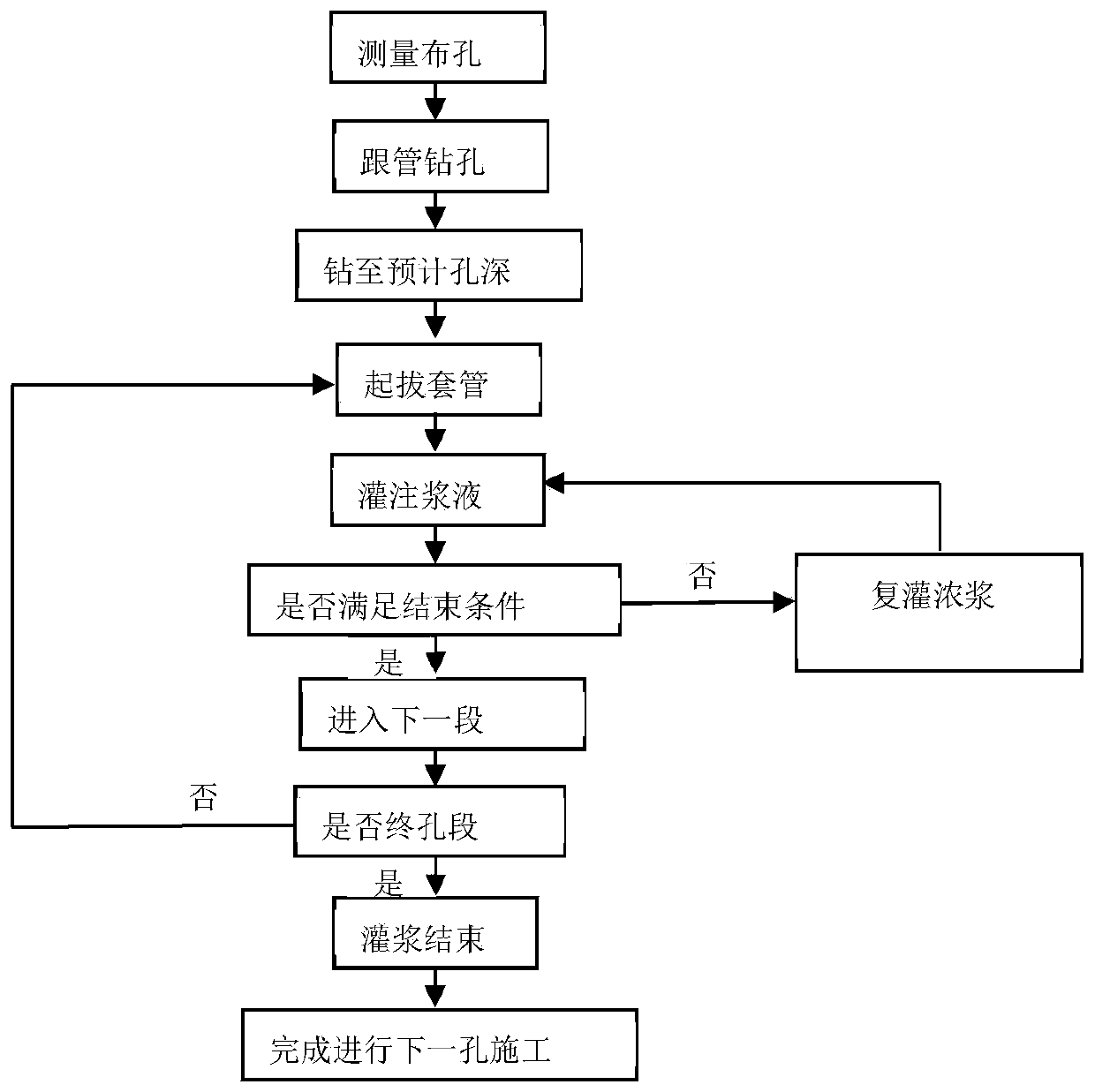

[0052] For the dam body whose boulder content exceeds 50%, the maximum particle size of the boulder exceeds 15 meters, and the depth of the cutoff wall exceeds 100 meters, the method of the present invention carries out blasting treatment (i.e., pre-explosion) in advance before the cutoff wall is formed into grooves. Carry out crushing treatment to the boulder (the flow chart is as follows Figure 6 Shown): First, drill a blast hole for placing explosives, then break the boulder in the blast hole by explosives. Below, the method of the present invention will be described in detail.

[0053] S11. Drilling blast holes

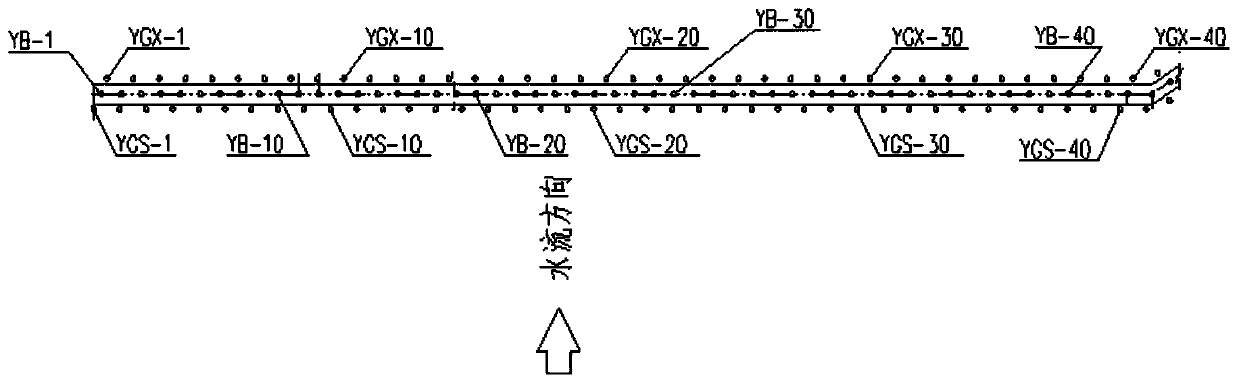

[0054] The present invention drills a row of blast holes (such as figure 1 As shown, the ones marked with YB in the figure are blast holes), and the distance between adjacent blast holes can be 1.2-1.6m, preferably 1.5m in this embodiment.

[0055] When drilling, drill to the maximum depth according to the geological conditions of the site construction and the co...

Embodiment 2

[0085] After blasting the large boulders in the formation, although there are no large boulders in the formation, because the formation after the blasting treatment is relatively loose, it is easy to appear during the grouting due to the loose formation during the trench construction of the cut-off wall. The phenomenon of hole collapse and grouting, therefore, this embodiment can also be on the basis of embodiment 1, in order to transform the stratum with loose and overhead phenomena into a uniform, stable and complete stratum, such as image 3 The shown method of drilling grouting holes in the above strata in advance and grouting the loose stratum through the grouting holes (that is, pre-filling) is used to improve the loose stratum. The method will be described in detail below.

[0086] S21, drilling and setting grouting holes

[0087] After the boulder is broken into a uniform stone, a row of upstream grouting with a depth of more than 70 meters is drilled at intervals upst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com