Grooving method of damming body anti-seepage wall

A technology of anti-seepage wall and damming body, which is applied in weirs, sea area engineering, construction, etc. It can solve the problems of high demolition cost, difficulty in construction of anti-seepage wall, and mud leakage, so as to achieve good construction quality and reduce collapse The effect of reducing the risk of trough and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

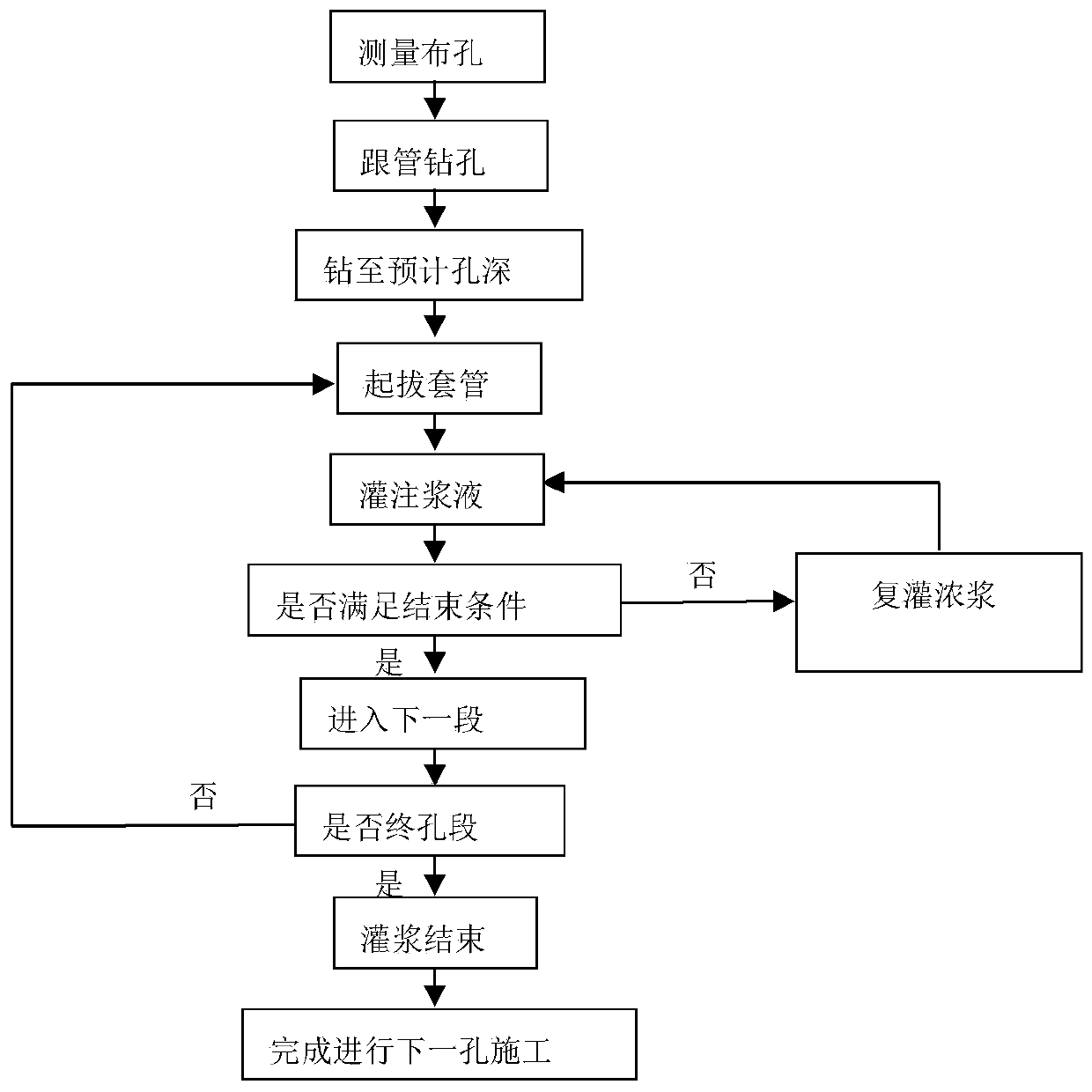

[0089] Among them, see Figure 7 , the first embodiment of the present invention for grouting the slots through the pouring conduit includes:

[0090] Connect the concrete pouring equipment to the pouring conduit;

[0091] According to the sliding speed of the sphere in the pouring conduit, the concrete pouring amount of the concrete pouring equipment is controlled, so that the concrete slowly follows the sphere and falls to the bottom of the slot until it is poured into a barrier body impervious wall.

[0092] Based on the axis of the anti-seepage wall of the dam body, the slot hole is formed through drilling and clearing construction, and then the pouring conduit is lowered, and the concrete pouring equipment is docked with the pouring conduit;

[0093] According to the sliding speed of the sphere in the pouring conduit, the concrete pouring amount of the concrete pouring equipment is controlled, so that the concrete slowly follows the sphere and falls to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com