Ore loading and unloading hopper wheel position inspection tool

A technology for loading and unloading materials and ore, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of large cumulative error, low inspection efficiency, spatial position error, etc., to achieve true inspection results, improve inspection efficiency, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

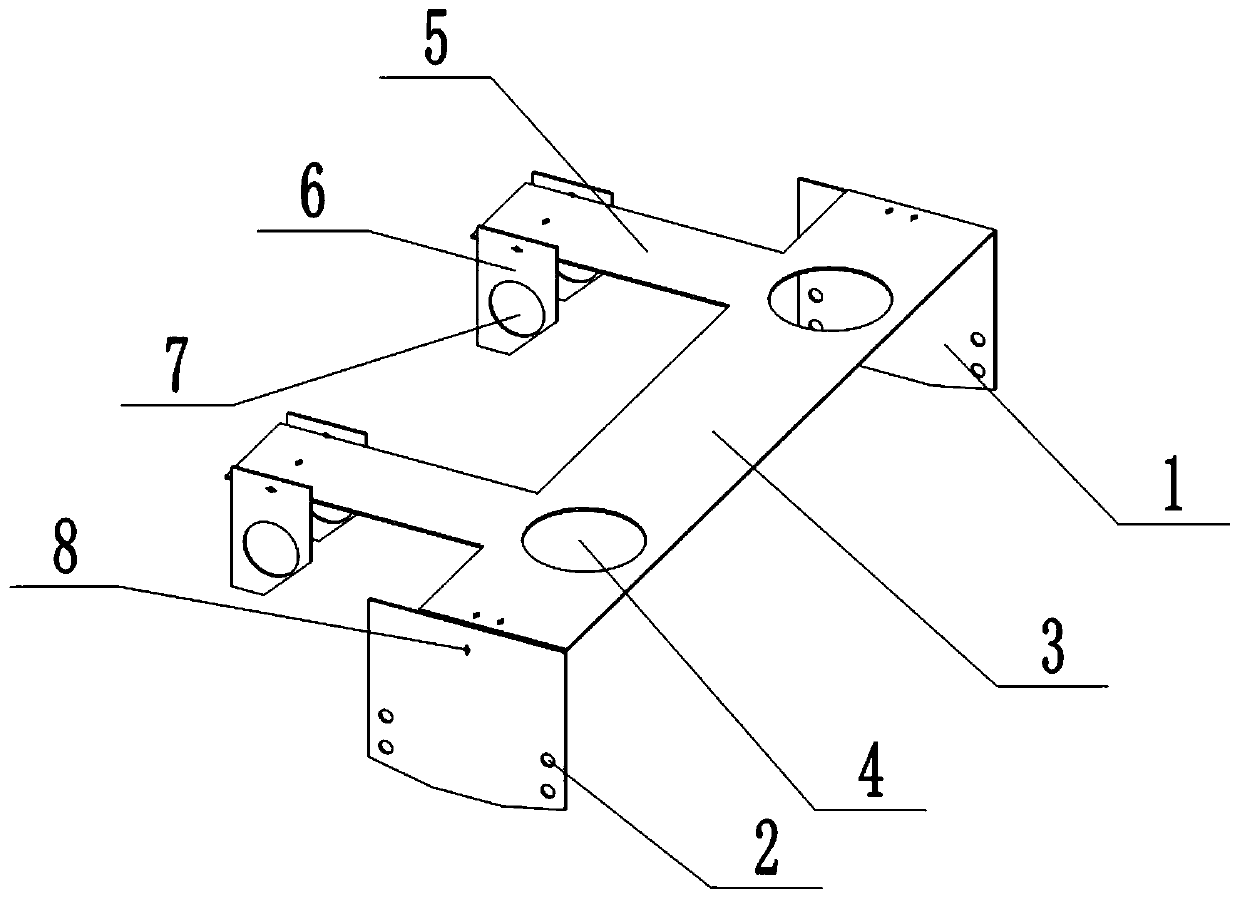

[0025] A wheel position inspection tool for an ore loading and unloading hopper, comprising two positioning side plates 1, the positioning side plate 1 is provided with a positioning hole 2 in cooperation with the connecting holes on the connecting plates 9 on both sides of the ore loading and unloading hopper, and the two positioning side plates 1 1 is provided with a top plate 3, the top plate 3 is vertically arranged with the positioning side plate 1, the two sides of the top plate 3 are fixedly connected with the tops of the two positioning side plates 1 respectively, and the top plate 3 is provided with two driving wheel observation holes 4 , during the inspection, the two driving wheel observation holes 4 are respectively located directly above the two driving wheel installation positions on the top of the ore loading and unloading hopper,

[0026] Two support plates 5 are fixed on the side of the top plate 3 close to the guide wheels of the ore loading and unloading hopp...

Embodiment 2

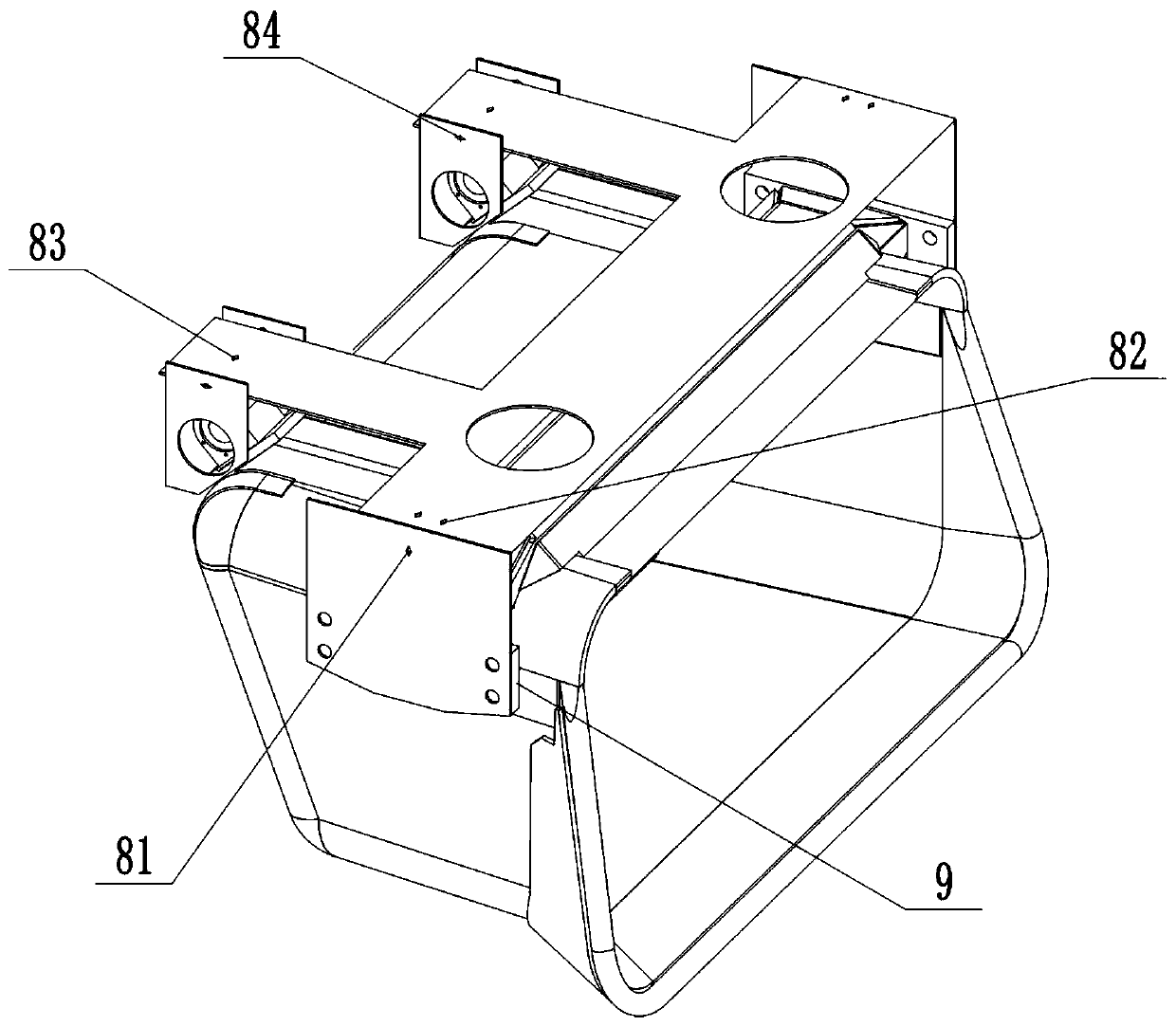

[0031] A wheel position inspection tool for an ore loading and unloading hopper, comprising two positioning side plates 1, the positioning side plate 1 is provided with a positioning hole 2 in cooperation with the connecting holes on the connecting plates 9 on both sides of the ore loading and unloading hopper, and the two positioning side plates 1 1 is provided with a top plate 3, the top plate 3 is vertically arranged with the positioning side plate 1, the two sides of the top plate 3 are fixedly connected with the tops of the two positioning side plates 1 respectively, and the top plate 3 is provided with two driving wheel observation holes 4 , during the inspection, the two driving wheel observation holes 4 are respectively located directly above the two driving wheel installation positions on the top of the ore loading and unloading hopper,

[0032] Two support plates 5 are fixed on the side of the top plate 3 close to the guide wheels of the ore loading and unloading hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com