Electronic equipment component heating control system and method

A technology for control systems and electronic equipment, applied in electrical components, ohmic resistance heating, electric heating devices, etc., can solve the problems of low temperature adaptability of electronic equipment components, small heating power requirements, etc., to solve the low temperature adaptability problem, heating power Small demand and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

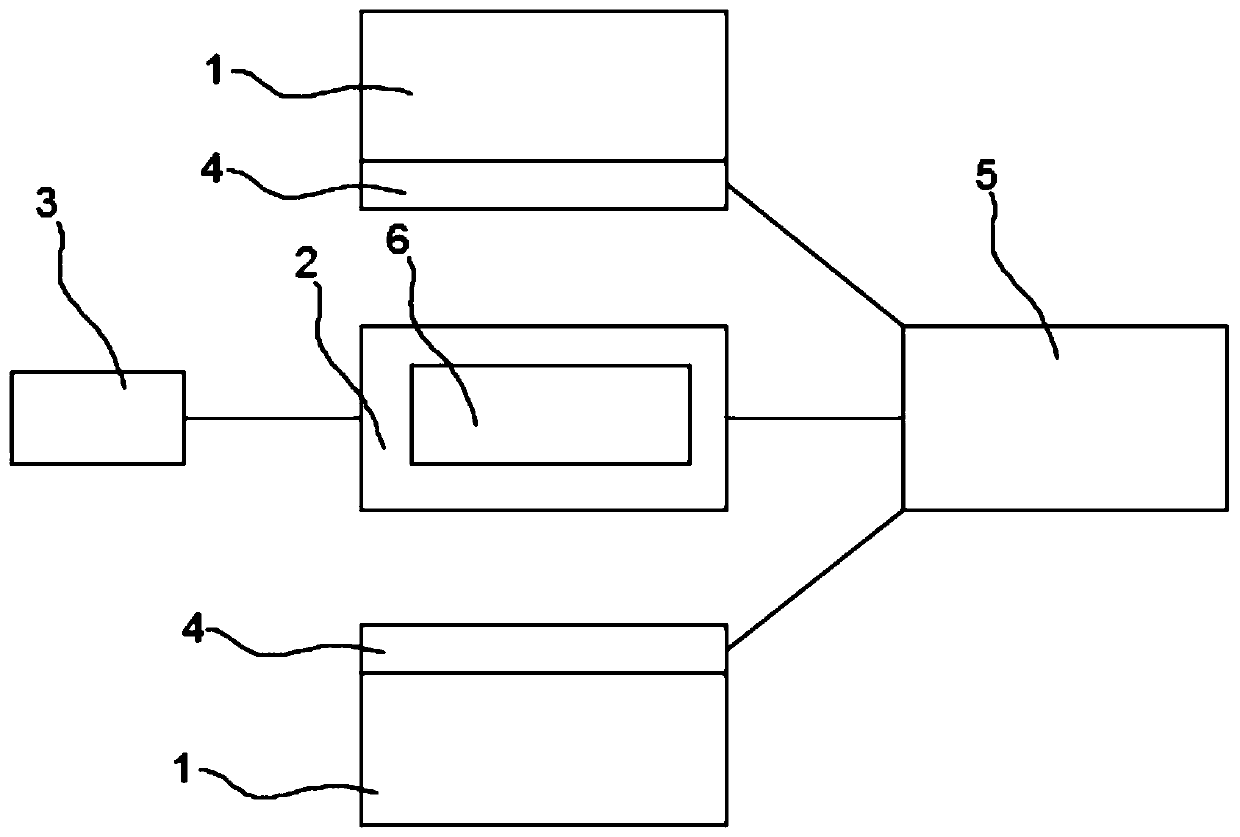

[0029] A heating control system for electronic equipment components, the system includes a circuit board 1, and an electric heating plate 2 equipped with a heater 6, two electric heating plates 2 are provided, and are distributed in parallel on the Both sides of circuit board 1.

[0030] Wherein, the bottom of the circuit board 1 is provided with a sensor 4, and the sensor 4 is connected with a controller 5, the controller 5 is connected with the electric heating plate 2, and the controller 5 is connected with a DC power supply module 3, and the DC power supply module 3 is connected with the electric heating plate 2. The heater 6 is connected, and then the DC power supply module 3 can supply power to the controller 5 and the heater 6 .

[0031] Furthermore, the heating power requirement is small and the heating is fast, and the problem of low temperature adaptability of electronic equipment components is solved without increasing the cost of electronic equipment to solve probl...

Embodiment 2

[0033] An embodiment of the present invention provides a heating control system for electronic equipment components, which is further defined on the basis of Embodiment 1.

[0034] Such as figure 1 As shown, the circuit board 1 and the sensor 4 are pasted and fixed.

[0035] The heater 6 is a thin film heater, and is pasted on the electric heating plate 2 .

[0036] Further, the heater 6 is pasted on the electric heating plate 2 through silicon rubber.

[0037] Optimally, the silicone rubber is GD414 silicone rubber.

[0038] Further, the thickness of the heater 6 is no more than 2mm.

Embodiment 3

[0040] The embodiment of the present invention is further limited on the basis of embodiment 1 and embodiment 2.

[0041] A control method for a heating control system of electronic equipment components, comprising the following steps:

[0042] Utilize the sensor 4 to collect the temperature of the circuit board 1 in real time, and feed back the collected temperature to the controller 5. The controller 5 compares the collected temperature with the set heating threshold temperature. If it does not exceed the heating threshold temperature, control The heater 6 starts heating work, and the temperature of the working environment of the circuit board 1 rises. At the same time, the controller 5 will compare the temperature of the real-time collected circuit board 1 with the set threshold temperature for stopping heating. , then the heater 6 is controlled to stop heating.

[0043] Furthermore, when the temperature is higher than a certain temperature, the heating is stopped, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com