A device and method for precise positioning of a rotary-type rotor-stator bearing a large axial load

An axial load and precise positioning technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of precise positioning and the difficulty of rotor axial load, and achieve the effect of good popularization, strong practicability and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

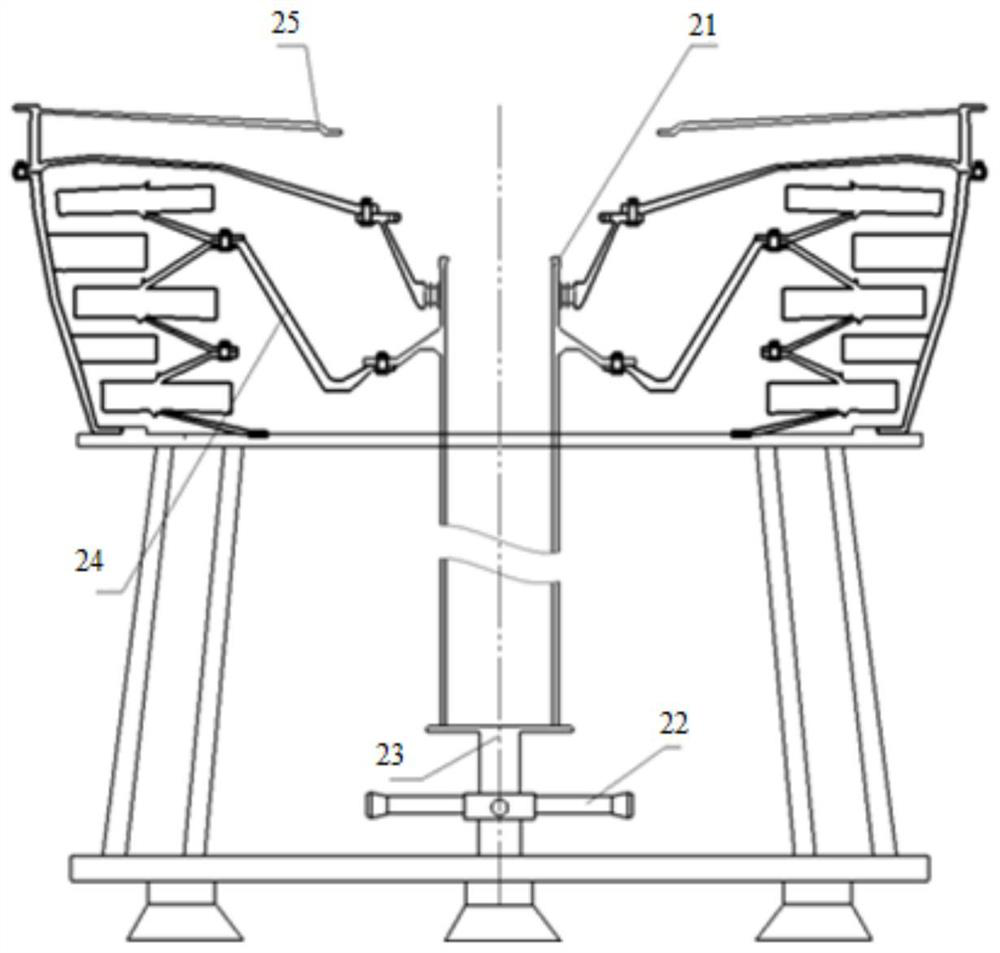

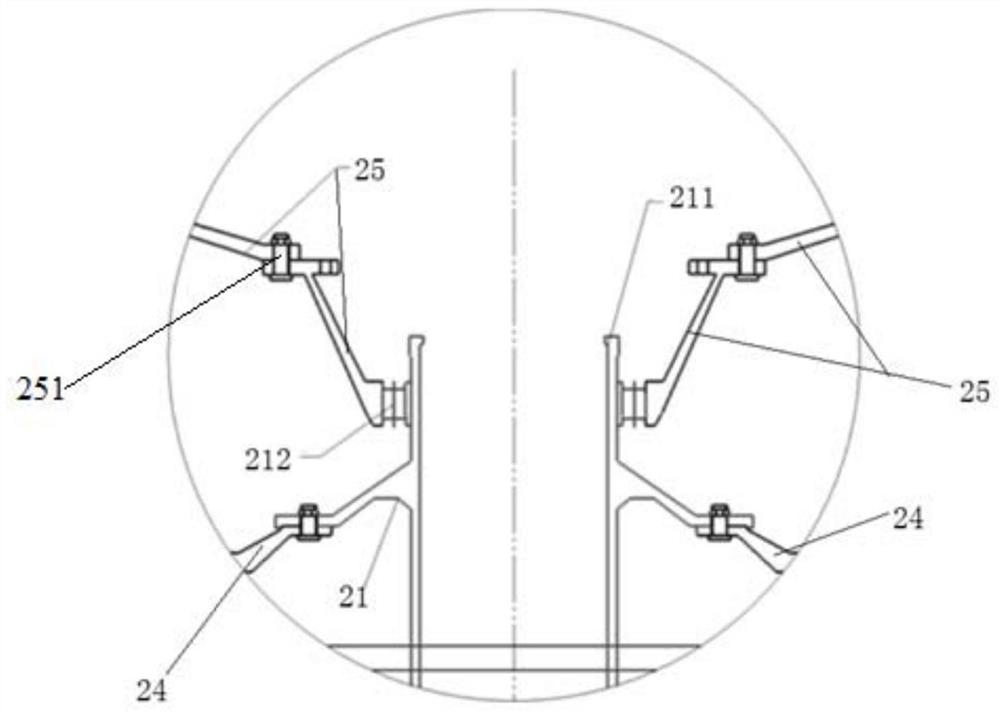

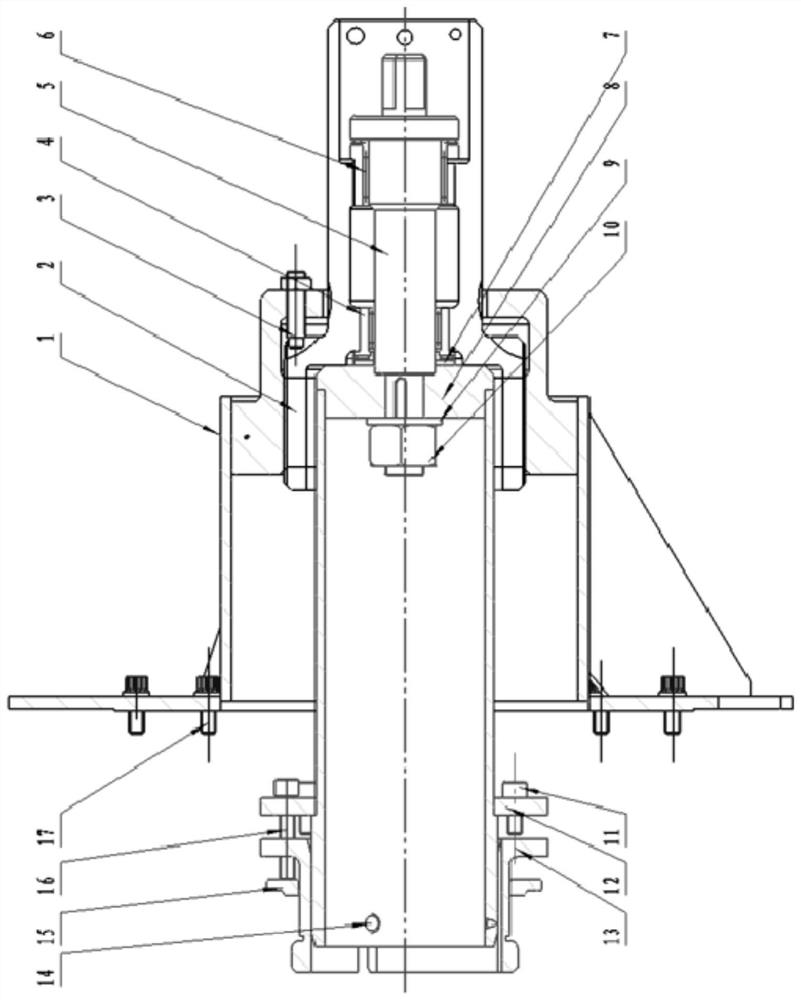

[0053] Precise Positioning Assembly Scheme Analysis

[0054] (1) Accurate positioning method of the rotary stator bearing large axial load:

[0055] ①Technical requirements: The rotor and stator can be precisely positioned in the axial direction, bear the weight of the rotor in the axial direction, and the rotor and stator can realize relative rotation;

[0056] ②Environmental structure:

[0057] a. The rotor part only exposes the tail section of the low vortex shaft at the load-bearing casing. The inner hole of the tail section has an annular groove structure, and the rear edge is a plane.

[0058] b. The bearing seat structure of the load-bearing casing is in radial contact with the bearing to transmit force, so axial positioning and bearing cannot be carried out.

[0059] c. The rear part of the load-bearing casing forms an open small space cone cavity, and the bearing seat structure has a mounting edge with threaded holes to connect with the load-bearing casing.

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com