a wheel

A wheel and hub technology applied to wheels. It can solve problems such as inability to play a role, and achieve the effect of solving laborious and convenient steps up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

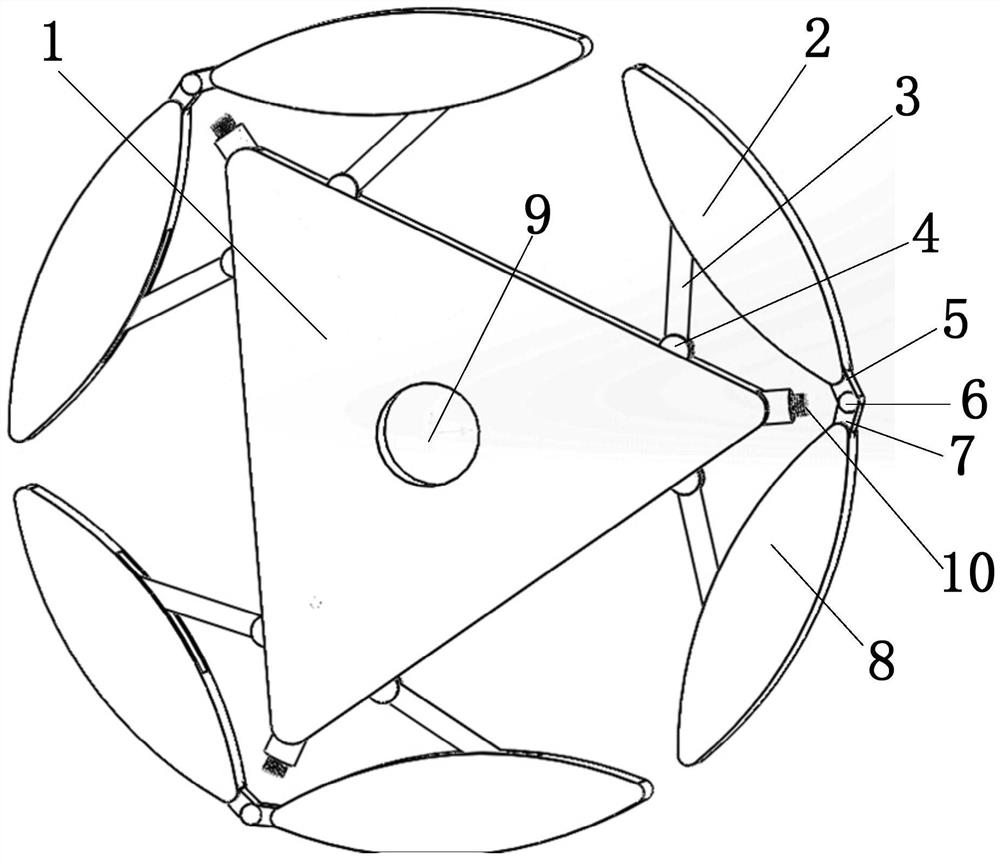

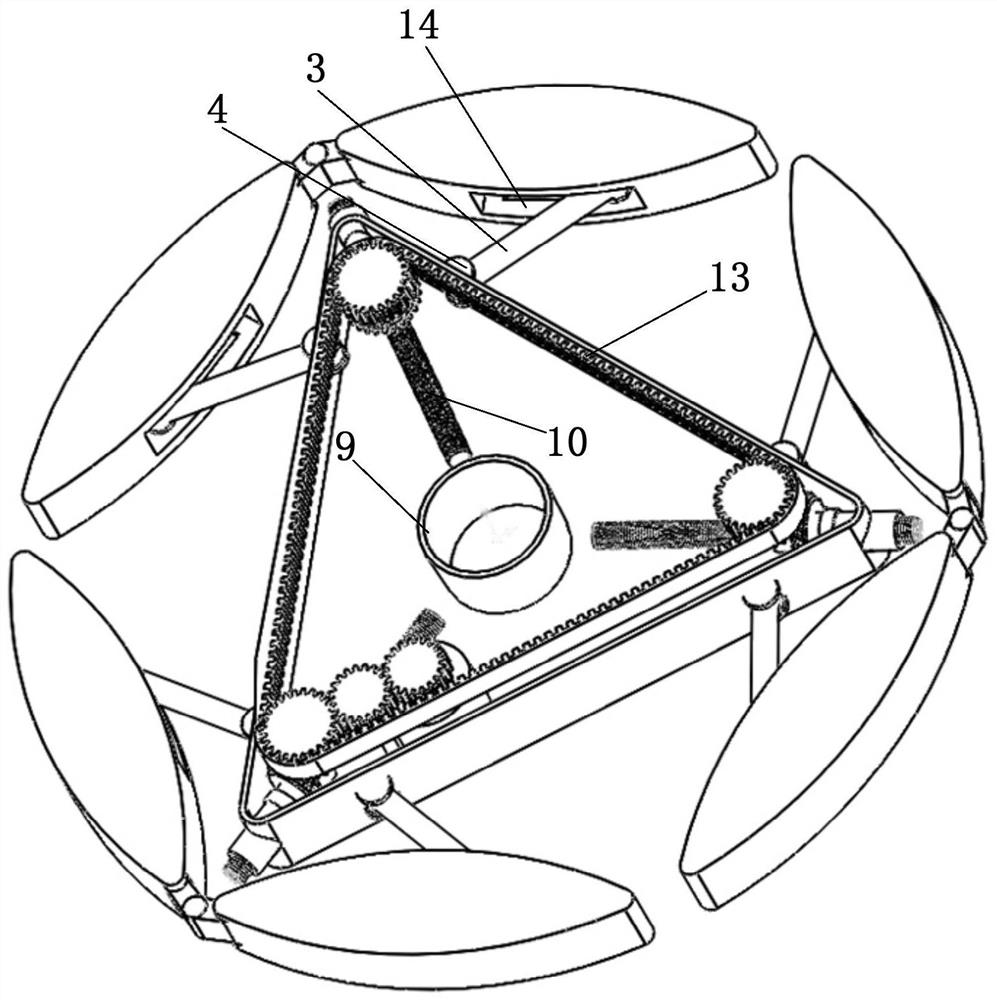

[0029] Such as Figure 1-6 The shown wheel includes a center frame and several pairs of arc hubs; each pair of arc hubs is connected to the center frame; several pairs of arc hubs form a complete hub, and each pair of arc hubs includes the first arc hub 2 and The second arc hub 8; the right end of the first arc hub 2 is connected with the left end of the second arc hub 8 by a hinge; A number of kinematic changing mechanisms that rotate at the hinge to change the kinematics of the wheel.

[0030] The movement form changing mechanism on the center frame rotates the first arc hub and the second arc hub on both sides of the hinge part 6 around the hinge, thereby realizing the shape change of the complete hub, thereby realizing the change of the movement form; the movement form is the movement The shape and condition of the complete hub at the time.

[0031] For example, when the distance between the hinge of the first arc hub and the second arc hub and the center frame was the s...

Embodiment 2

[0036] Such as Figure 1-6The shown wheel includes a center frame and several pairs of arc hubs; each pair of arc hubs is connected to the center frame; several pairs of arc hubs form a complete hub, and each pair of arc hubs includes the first arc hub 2 and The second arc hub 8; the first connecting block 5 on the right-hand side of the first arc hub 2 is connected with the second connecting block 7 on the left end of the second arc hub 8 by a hinge 6; A plurality of movement form changing mechanisms are used to rotate the first arc hub and the second arc hub around the hinge to change the movement form of the wheels. Preferably, when the distance between the hinge portion of the complete hub and the center frame is the farthest, the section of the complete hub is a circular structure; when the distance between the hinge portion of the complete hub and the center frame is the shortest, the cross section of the complete hub is It is a Lello triangle structure.

[0037] In th...

Embodiment 3

[0045] This embodiment is further improved and optimized on the basis of embodiment 2 as follows.

[0046] Such as Figure 1-6 The shown wheel includes a center frame and several pairs of arc hubs; each pair of arc hubs is connected to the center frame; several pairs of arc hubs form a complete hub, and each pair of arc hubs includes the first arc hub 2 and The second arc hub 8; the first connecting block 5 on the right-hand side of the first arc hub 2 is connected with the second connecting block 7 on the left end of the second arc hub 8 by a hinge 6; A plurality of movement form changing mechanisms are used to rotate the first arc hub and the second arc hub around the hinge to change the movement form of the wheel.

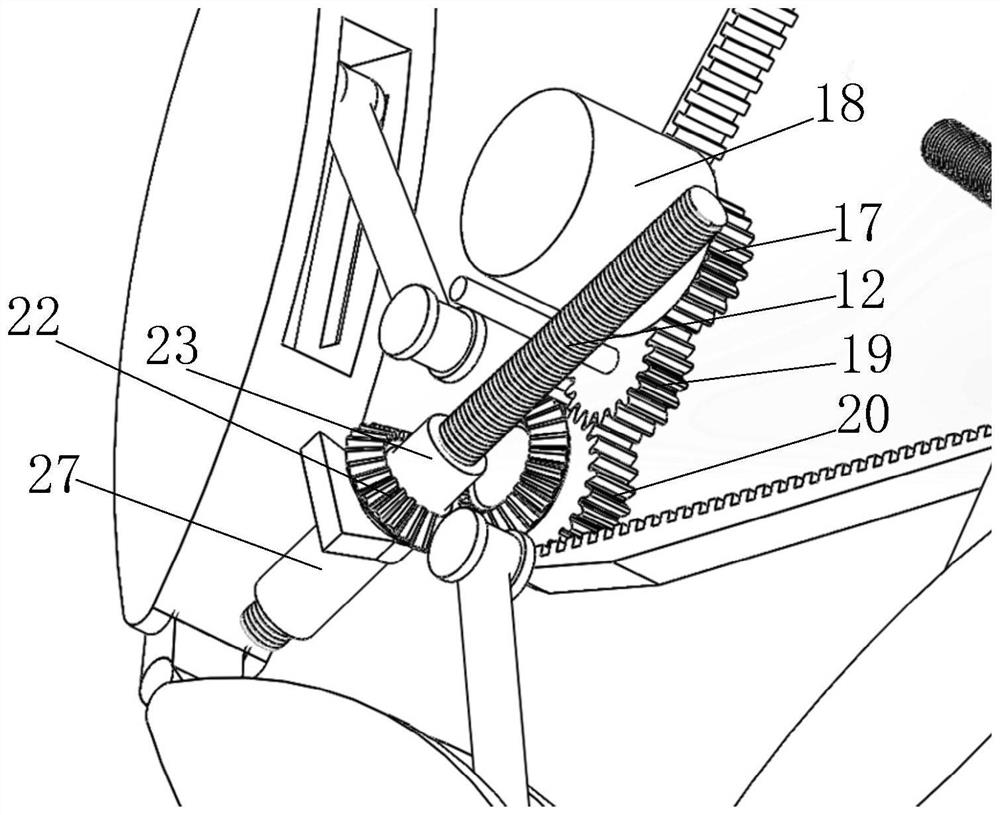

[0047] Each movement form changing structure includes: a retractable mechanism, a telescopic mechanism and a power mechanism. Specifically, the retractable mechanism is used to retract the upper end of the first arc hub and the lower end of the second arc hub ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com