Two-stage oil-water separator

A technology of oil-water separation and oil-water separation device, applied in liquid separation, separation method, multi-stage water treatment, etc., can solve problems such as easy air suction, temperature rise failure, and easy pump failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

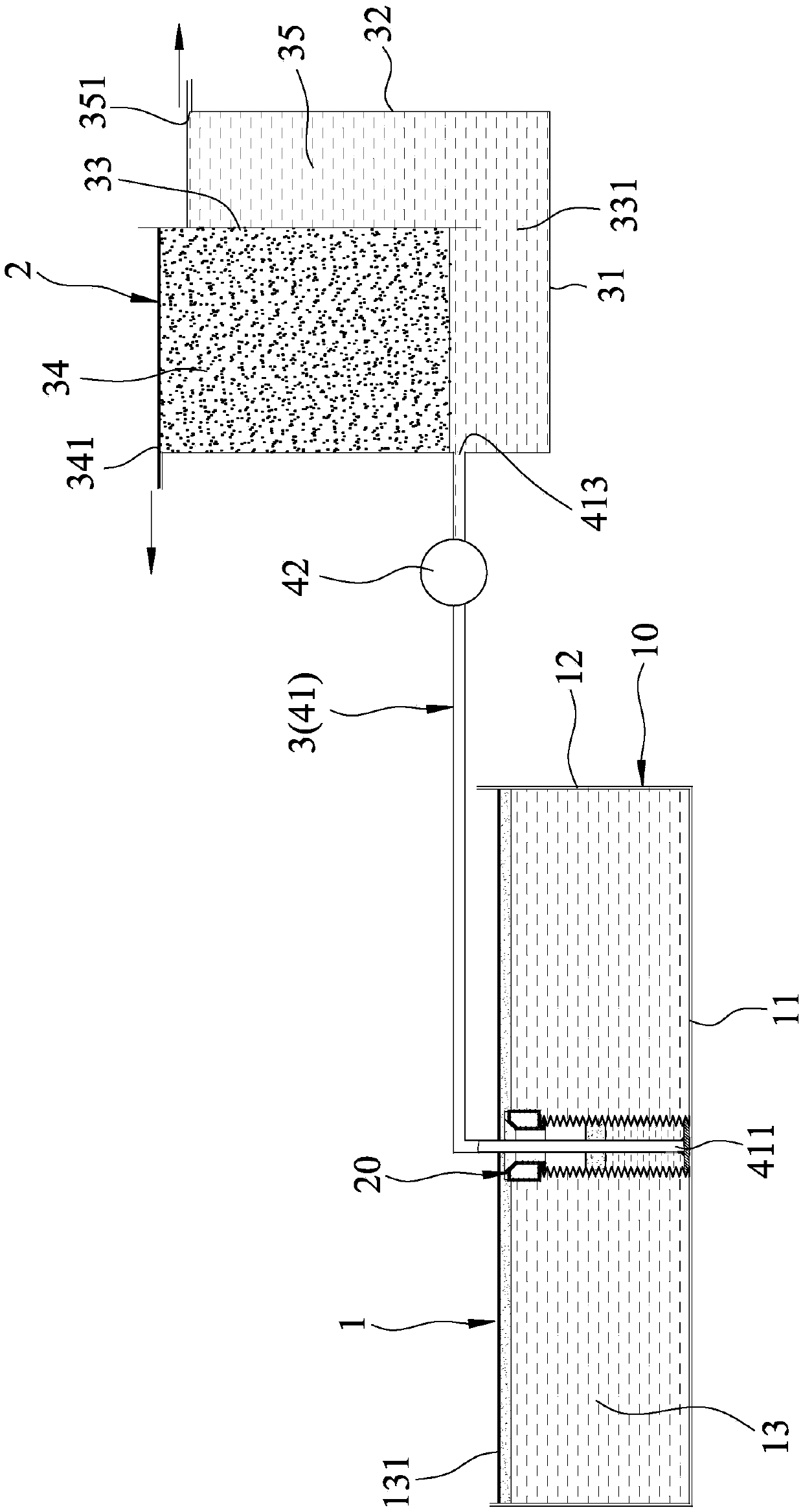

[0018] refer to figure 1 and figure 2 , an embodiment of the two-stage oil-water separator of the present invention includes a first oil-water separator 1 , a second oil-water separator 2 and a pumping unit 3 .

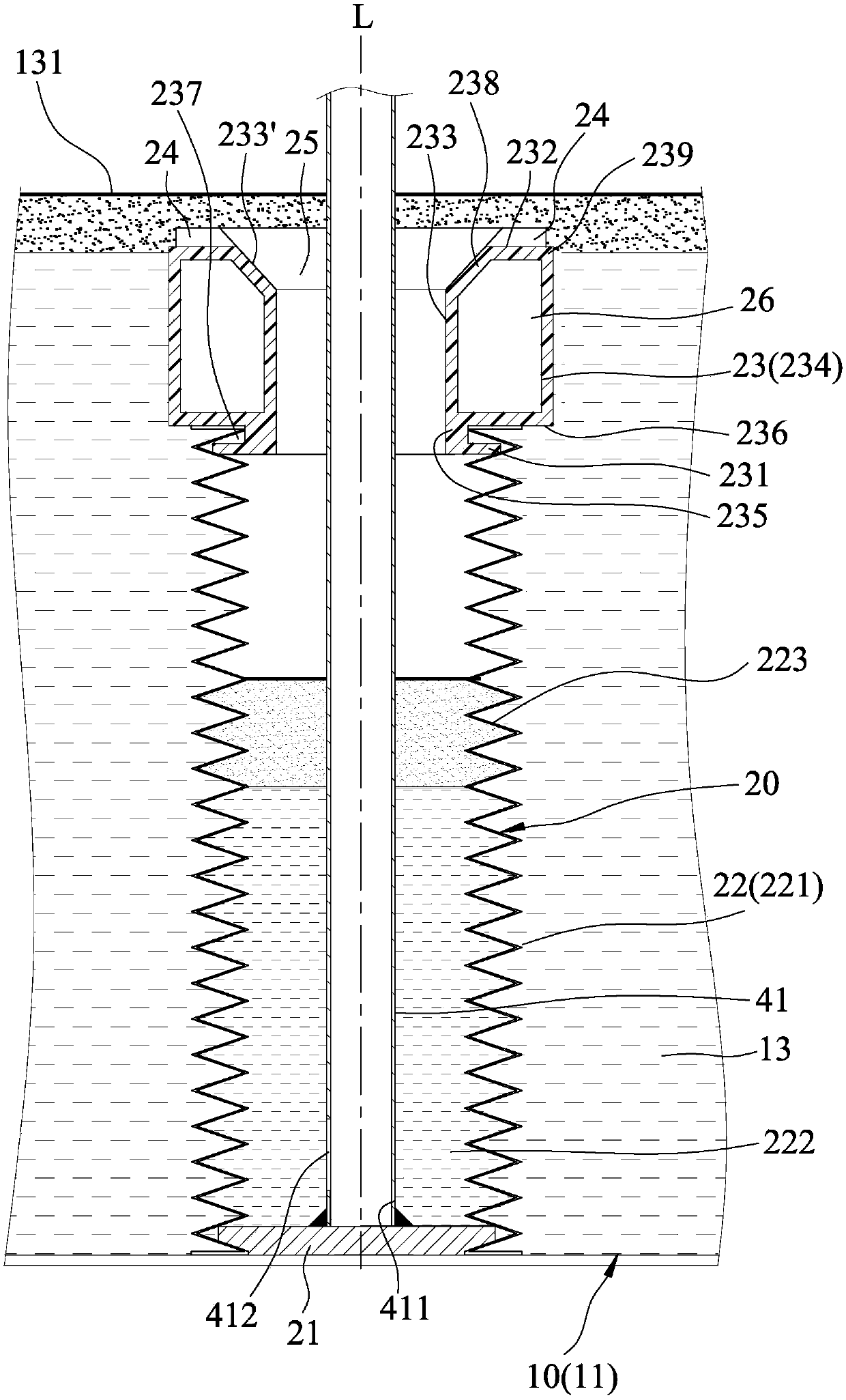

[0019] The first oil-water separation device 1 includes a first liquid storage barrel 10 and a floating unit 20 installed inside the first liquid storage barrel 10 .

[0020] The first liquid storage barrel 10 has a first bottom wall 11, a first peripheral wall 12 extending upward from the peripheral edge of the first bottom wall 11, the first bottom wall 11 and the first peripheral wall 12 are jointly defined A first liquid storage chamber 13 with a notch 131 facing upward.

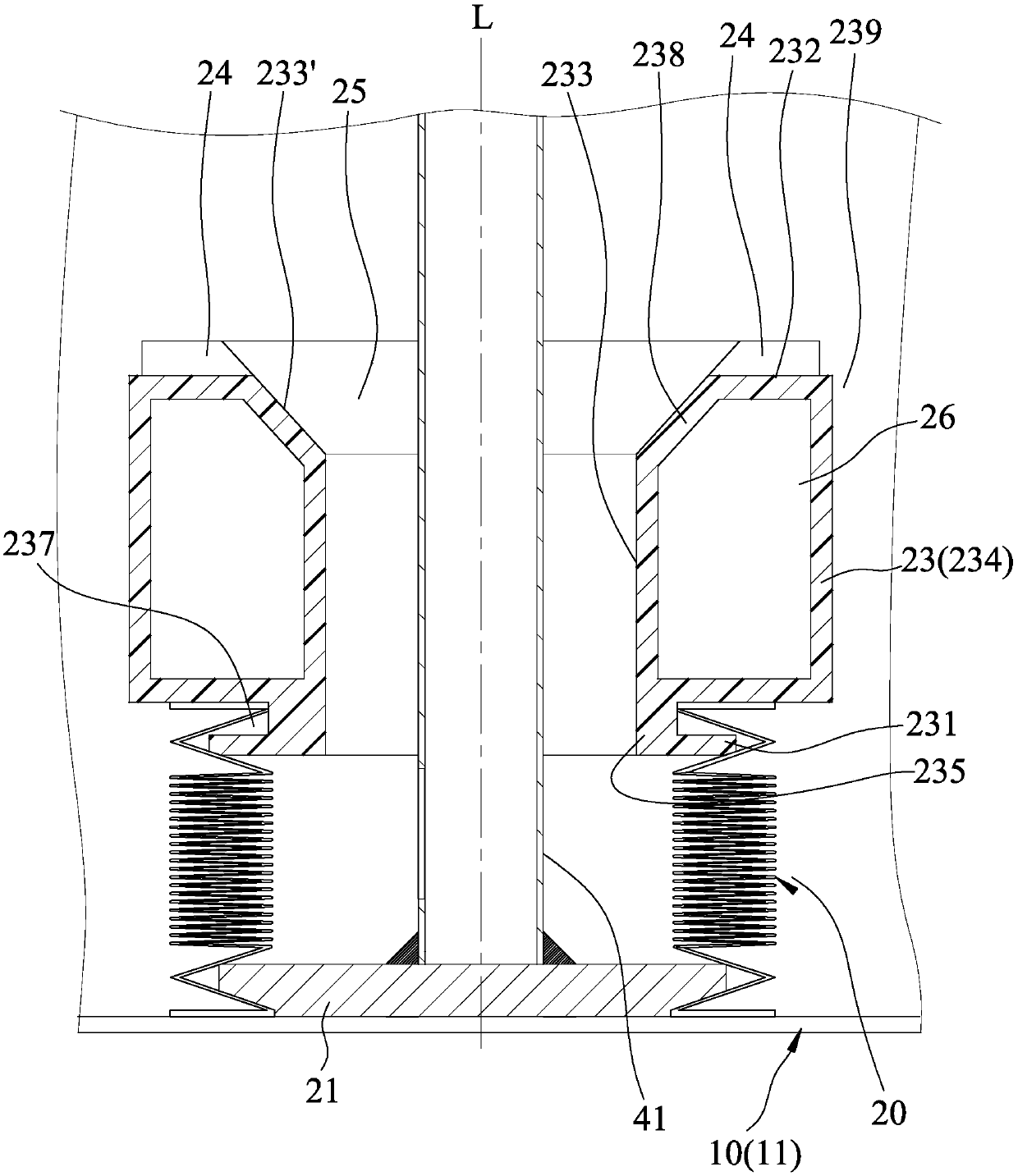

[0021] The floating unit 20 has a fixed seat 21 fixed to the first bottom wall 11, a telescopic tube 22 extending along an axis L and connected to the fixed seat 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com