Rose oil distillation purification unit

A technology of rose oil and collection device, which is applied in the direction of essential oil/fragrance, fat production, etc. It can solve problems such as difficult to clean, easy to be heated and zoomed, and does not meet the principles of energy saving and emission reduction, so as to improve utilization rate, reasonable structure, and avoid burning. coke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

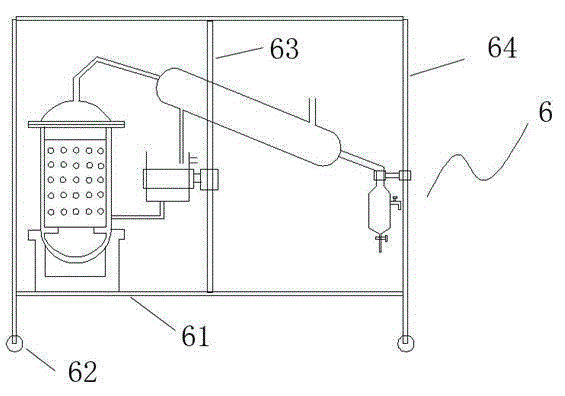

[0022] Below in conjunction with each accompanying drawing and embodiment the present invention will be further described:

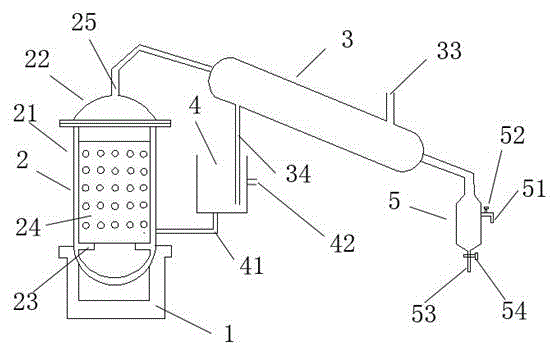

[0023] Such as figure 1 Shown:

[0024] A rose oil distillation and purification device comprises an electric heating jacket 1, a glass reaction kettle 2, a condensation device 3, a water supply cup 4 and an oil liquid collection device 5. Among them, the glass reactor 2 includes a kettle body 21 and a kettle cover 22. The upper end of the kettle body 21 is cylindrical and the lower end is hemispherical. The lower end of the kettle body 21 is placed directly above the electric heating jacket 1. Hole 25, the glass reaction kettle 2 is provided with a stainless steel net barrel 24, the still body 21 is provided with a circle of bumps 23 at the cylinder and the hemispherical connection part, and the stainless steel net barrel 24 rests on the bumps 23.

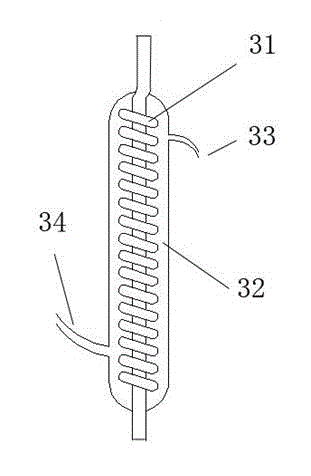

[0025] The condensing device 3 is connected to the steam through hole 25 and the oil collecting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com