An experimental device for bolt tightening to ensure coaxiality

An experimental device, coaxiality technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as the inability to meet the requirements of coaxiality of bolted connection structures, and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description in conjunction with the accompanying drawings of the experimental apparatus described in further detail.

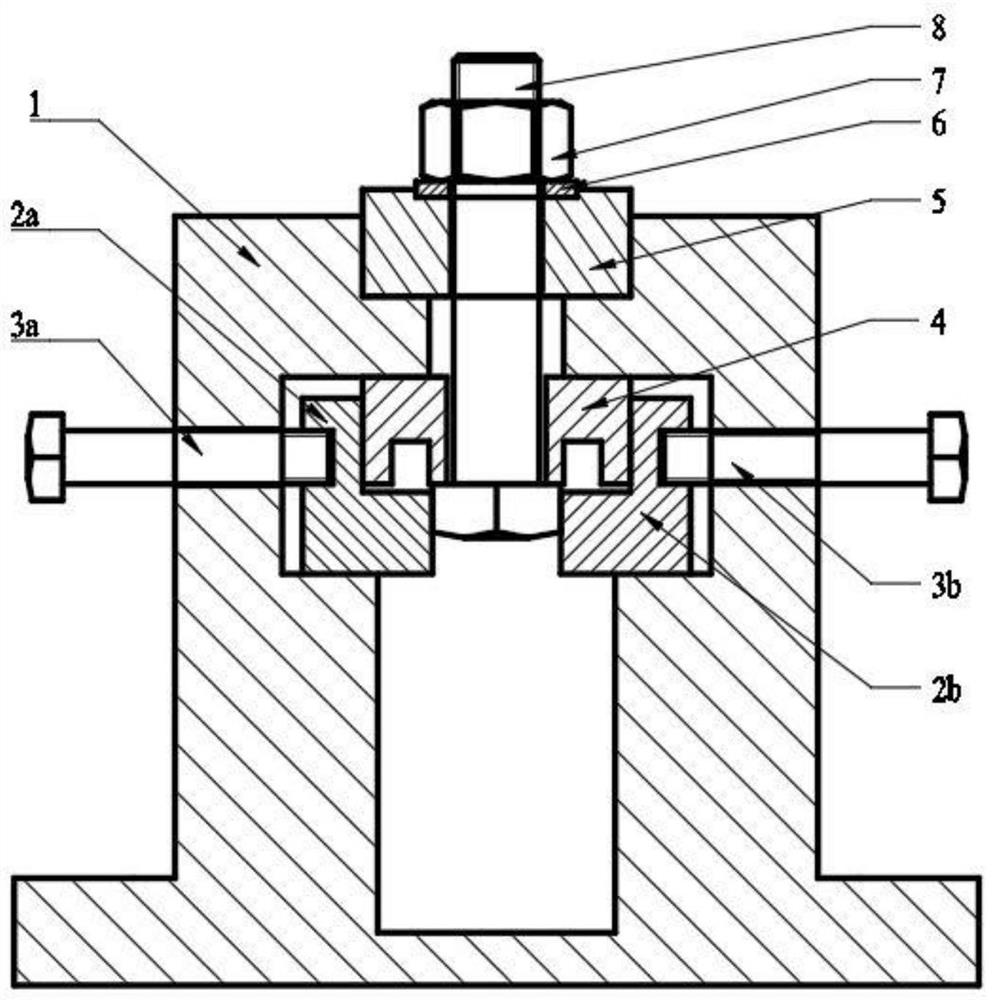

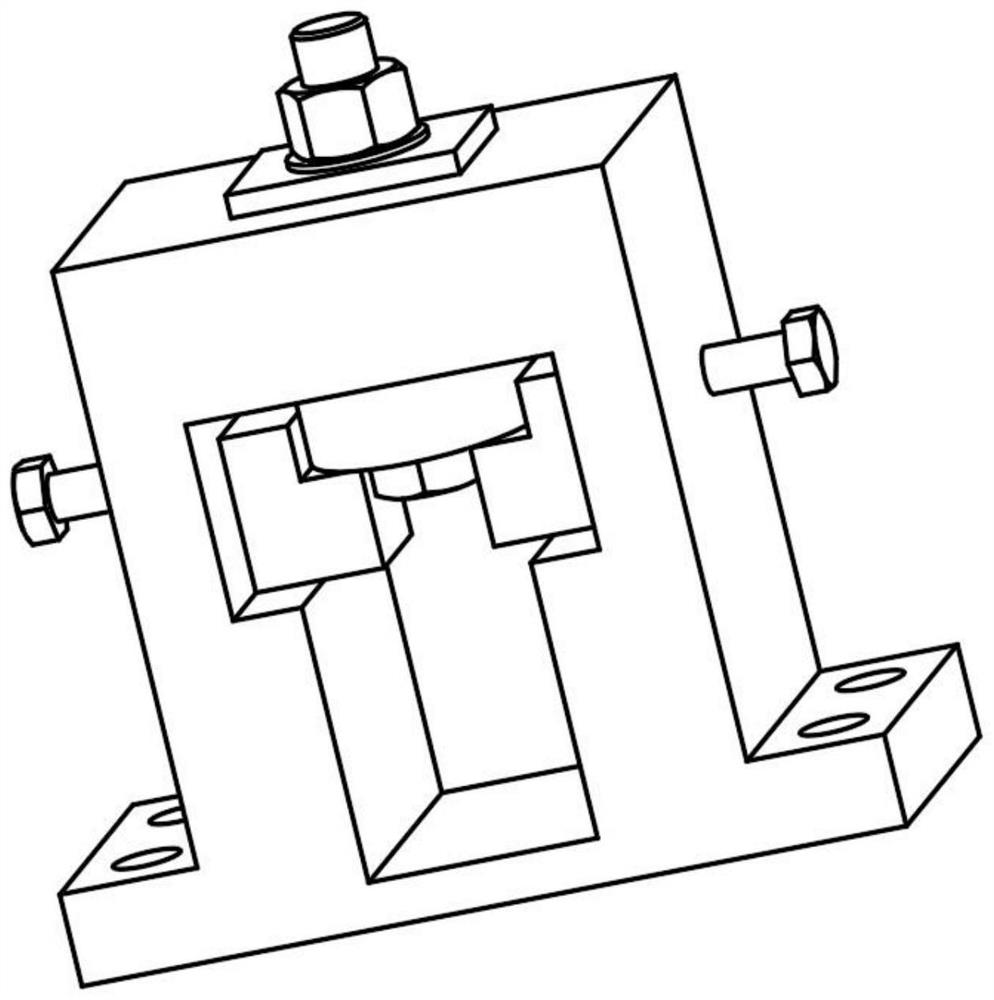

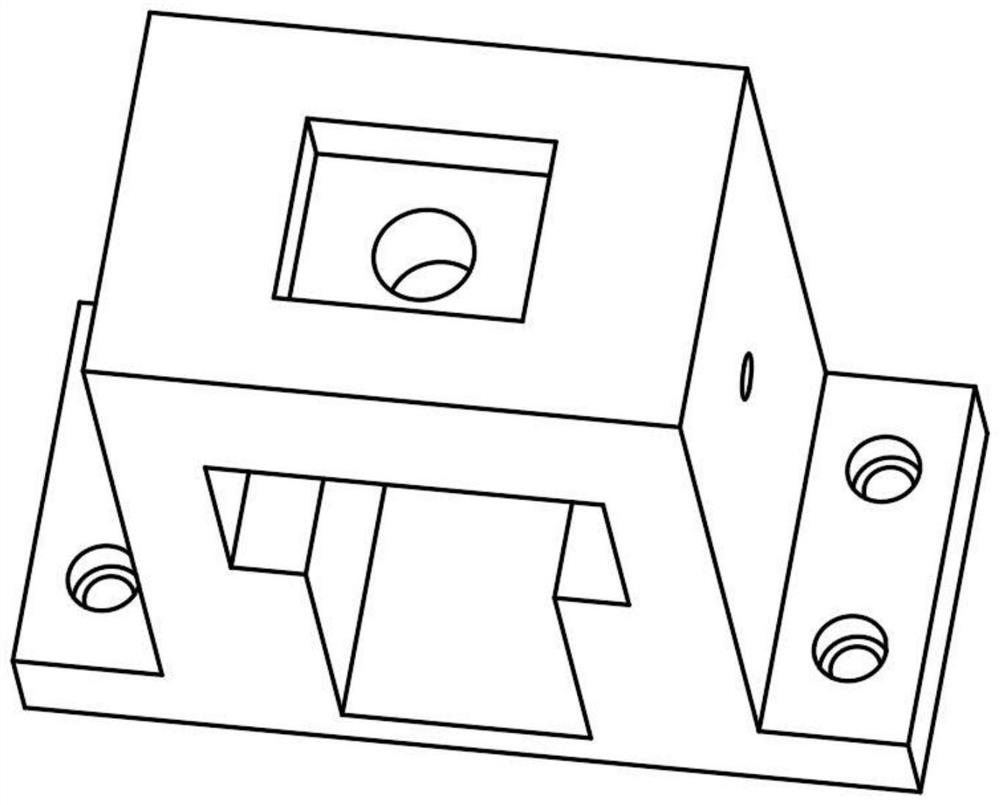

[0014] like figure 1 The one shown fastening bolt experimental apparatus to ensure concentricity. There are four holes in the jig main body 1, for the fixed plate or bench. Fastening the two sliders (2a and 2b) is placed over the jig main body 1 within the T-slot, the feed screw (3a and 3b) mounted on the jig main body 1 symmetrically arranged on both sides of the threaded hole, and allowed to through fastening two sliders (2a and 2b) of the blind hole. Adjusting the position of the initial feed screw (3a and 3b), and leave enough space for the installation of the pressure sensor 4 is annular. Custom clamping jaws clamp 5 is placed in a rectangular groove of the upper body, and then fastening the gasket 6 used in the experiment is placed in the upper portion of the clamping block 5 customized annular groove to ensure that the gasket 6, clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com