Special-purpose disk spring type clamping and loosening device of lathe

The technology of a special lathe and a disc spring is applied in the field of disc spring type clamping and releasing devices for special lathes, which can solve the problem that the coaxiality of the processed workpiece cannot meet the specified requirements, the assembly and maintenance are inconvenient, and the expansion of the chuck is uneven, etc. problems, to achieve the effect of simple structure, convenient assembly and maintenance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

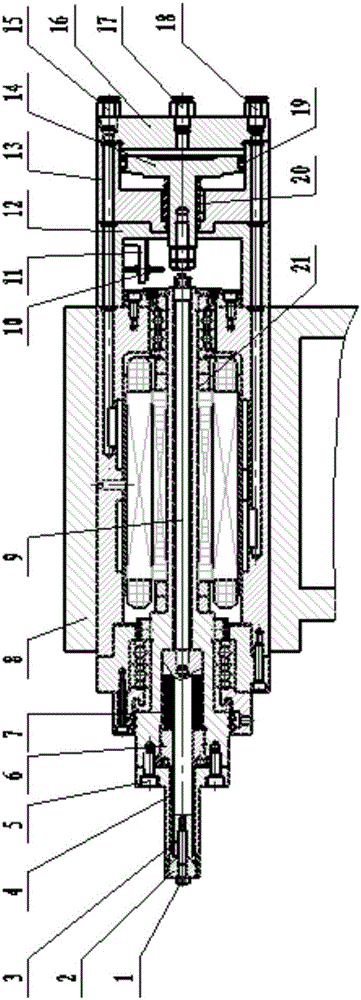

[0016] like figure 1 As shown, the electric spindle 21 is installed in the spindle box 8, which together constitute the main part of the spindle. The push rod 9 is sleeved on the hollow part of the electric spindle 21, one end of which protrudes, and the other end is connected with one side of the pull stud 3 through threads. The collet 4 is assembled on one side of the electric spindle with the mounting screw 5, and the collet 4 is cut into 6 petals on the side of the mounting screw to facilitate expansion and tightening of the workpiece. The collet 4 is covered with a disc spring 7, one side of the disc spring 7 is in contact with the boss of the collet 4, and the other side is pressed by the support sleeve 6 installed in the center of the electric spindle 21. The other side of the pull stud 3 is connected with the tensioning steel ball 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com