Valve core component and thermal expansion valve using same

A valve core and component technology, used in the field of thermal expansion valves, can solve the problems of poor parallelism between the upper end face and the support part, affecting the valve adjustment accuracy and sealing, and the inability to guarantee the coaxiality of the valve port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Figure 9 A typical refrigerating flow diagram of a thermal expansion valve applied to a refrigerating system given in the present invention.

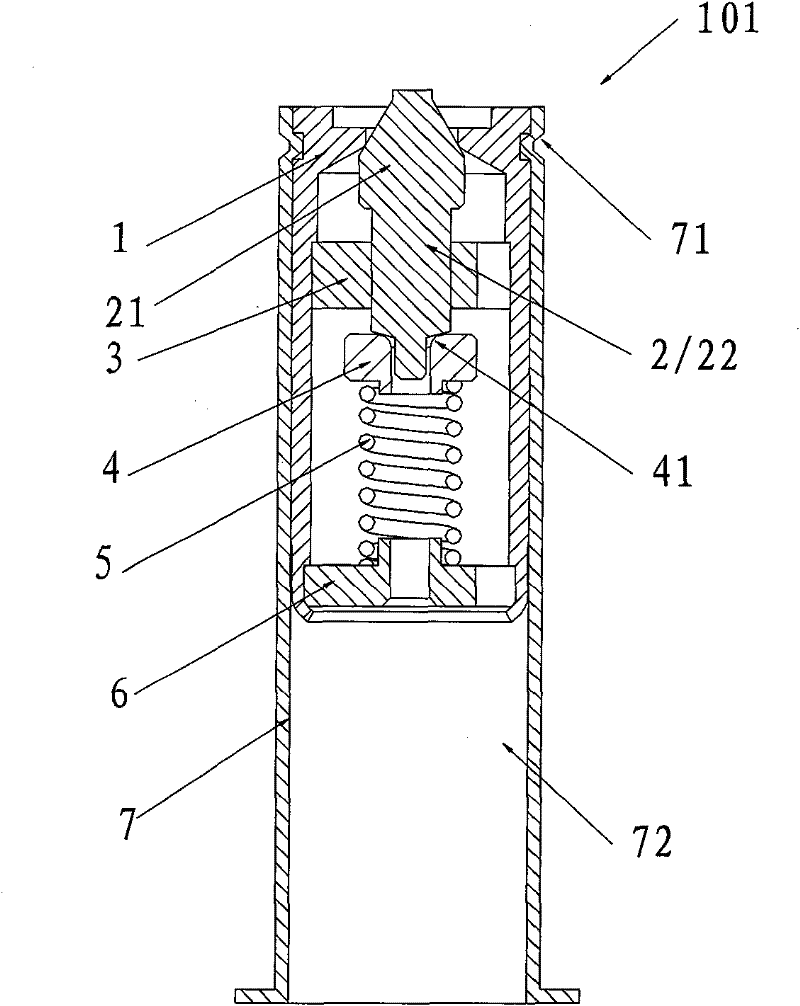

[0058] Such as Figure 9shown. In this refrigeration system, an expansion valve 100 is connected between an evaporator 200 and a condenser 300 . The expansion valve 100 includes a valve body 102 , and an inner cavity 107 extending longitudinally through the valve body 102 , the flow path inlet 108 communicates with the condenser 300 , and the flow path outlet 109 communicates with the evaporator 200 . One end of the valve body 102 is fixed with an air box head as a temperature-sensitive part 103, and the air box head is made up of an air box seat 1031, a transmission plate 1032, a diaphragm 1033, and an air box cover 1034 welded together, and the diaphragm 1033 and the air box cover 1034 are welded. The sealed cavity between them is filled with refrigerant, and communicates with the inner cavity of the sensor 500 arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com