Conveying sorting equipment with buffering material receiving function

A function and equipment technology, applied in the field of conveying and sorting equipment with buffering and receiving functions, can solve the problems of increasing operating costs, reducing manpower, reducing factory operating costs, etc., to increase efficiency, protect qualified rates, save The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

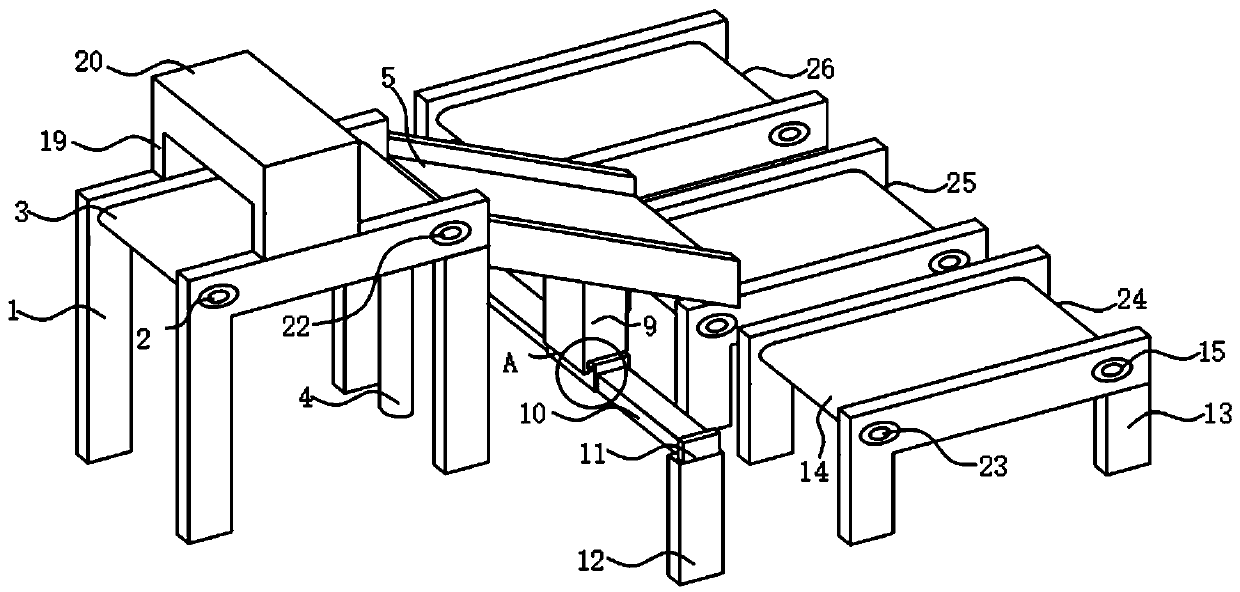

[0030] Such as Figure 1-7 As shown, a kind of conveying and sorting equipment with the function of buffering and receiving materials includes No. 1 conveyor belt bracket 1, No. 2 conveying device 24, No. 3 conveying device 25, No. 4 conveying device 26, fixed bracket 4 and conveying plate 5, No. 2 conveyer 24 is positioned at the side of No. 3 conveyer 25, and No. 3 conveyer 25 is positioned at the side of No. 4 conveyer 26, and the upper end of No. 1 conveyer belt bracket 1 is provided with three-dimensional laser scanning device 19, and three-dimensional laser scanning device 19 is provided with a central processing unit inside, the No. 2 conveying device 24 includes No. 2 conveyor belt support 13, the upper end of No. 1 conveyor belt support 1 is provided with No. 1 driving shaft 2 and No. 1 driven shaft 22, No. 1 driving shaft 2 and No. 1 driven shaft No. 1 driven shaft 22 is movably connected to No. 1 conveyor belt 3 on its peripheral surface, and buffer plates 6 are fix...

Embodiment 2

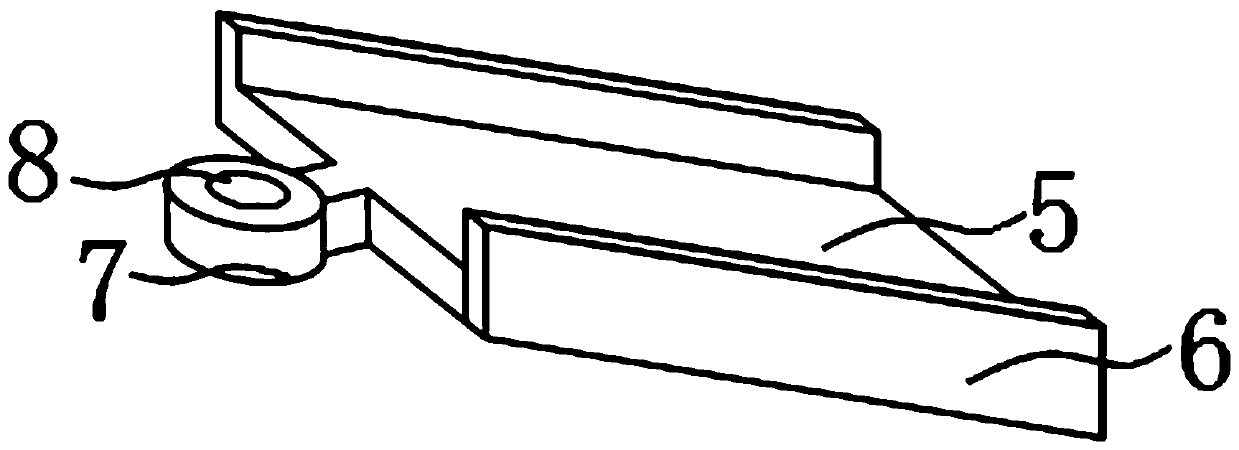

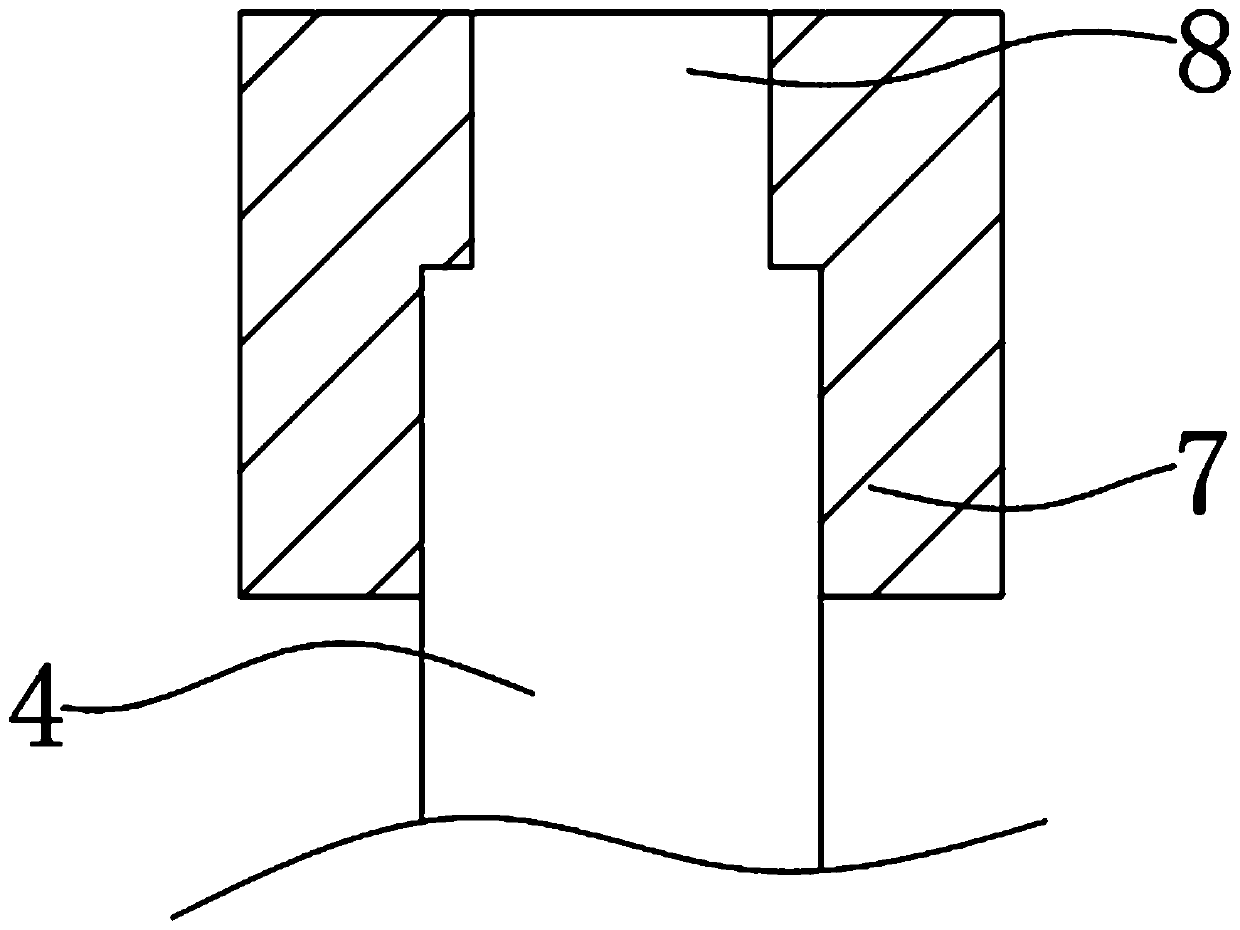

[0036] Such as Figure 1-7 As shown, a kind of conveying and sorting equipment with the function of buffering and receiving materials includes a three-dimensional laser scanning device 19 including a scanner main body 20, a three-dimensional laser scanner 21 is fixedly connected to the outer surface of the lower end of the scanner main body 20, and a cylinder support 12 The upper end is fixedly connected with a cylinder frame 11, one side of the cylinder frame 11 is fixedly connected with a cylinder main body 10, the upper surface of the cylinder body 10 is movably connected with a piston frame 16, and the upper end of the conveying plate 5 is provided with a rotating shaft 7, and the inside of the rotating shaft 7 is provided with a No. 1 groove 8, and the No. 1 groove 8 is a cylindrical structure with a small upper part and a larger lower part. The fixed bracket 4 is movably connected with the No. 1 groove 8 inside the rotating shaft 7, so that the conveying plate 5 can rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com