Cooking equipment capable of uniformly wiping absorption cores by roller screen and shuttle in production process of sanitary napkins

A production process and cooking equipment technology, applied in the field of sanitary napkin cooking, can solve the problems of sanitary napkins such as loss of elasticity, uneven quality, size cooking deformation, etc., to achieve the overall pass rate of protection, avoid unilateral swelling, and strong elastic quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

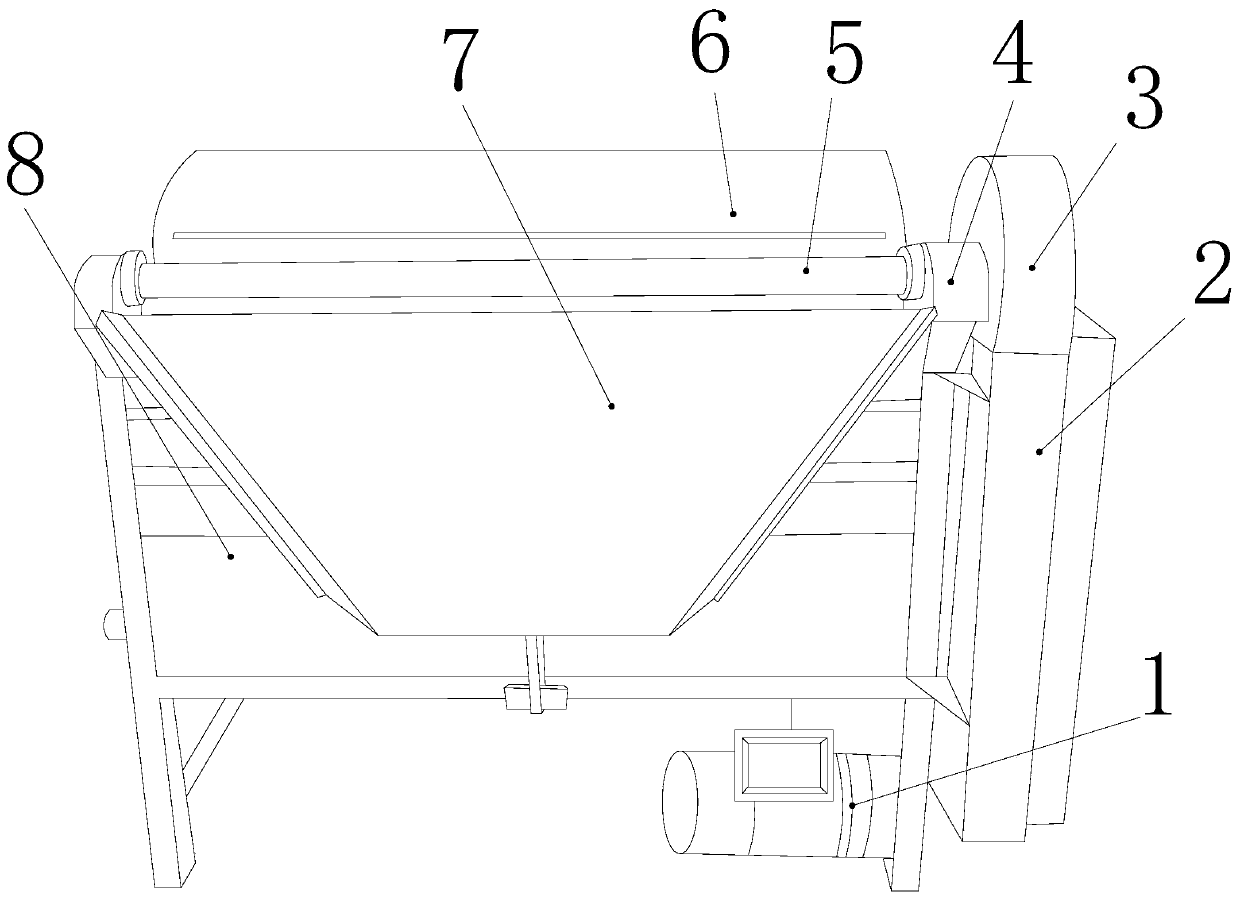

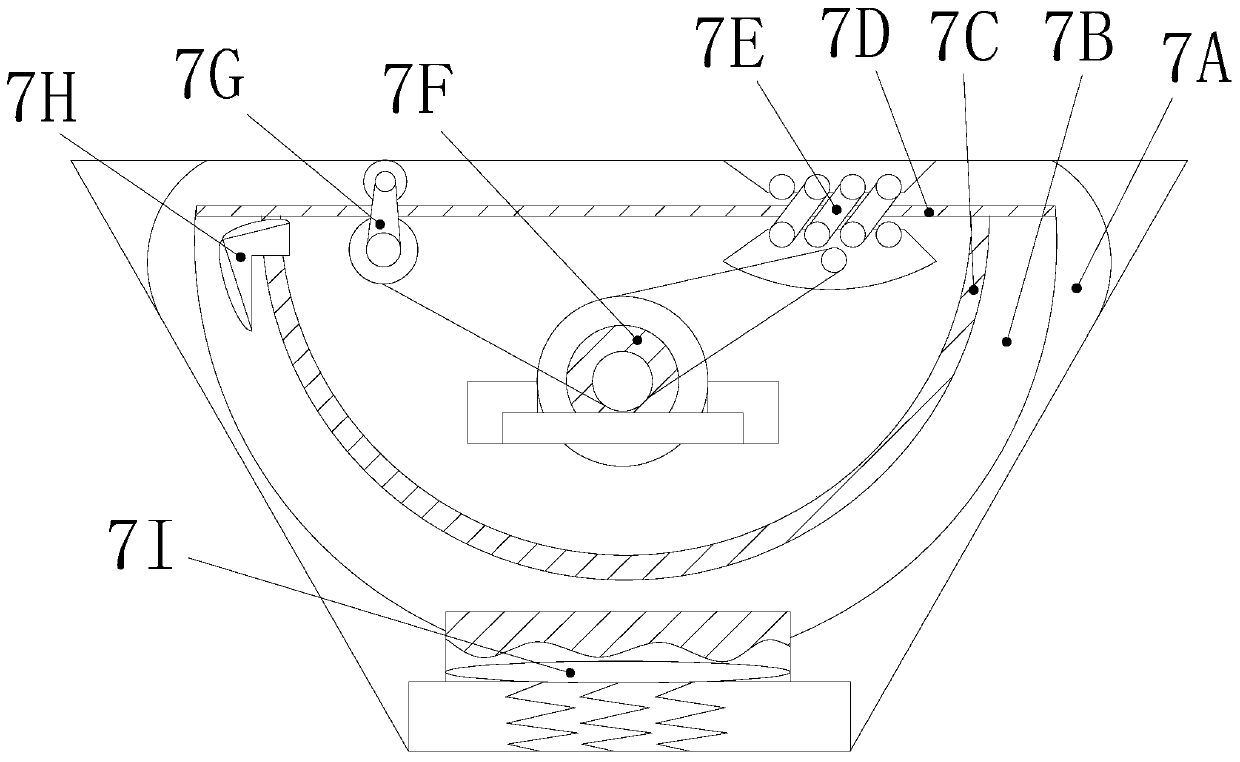

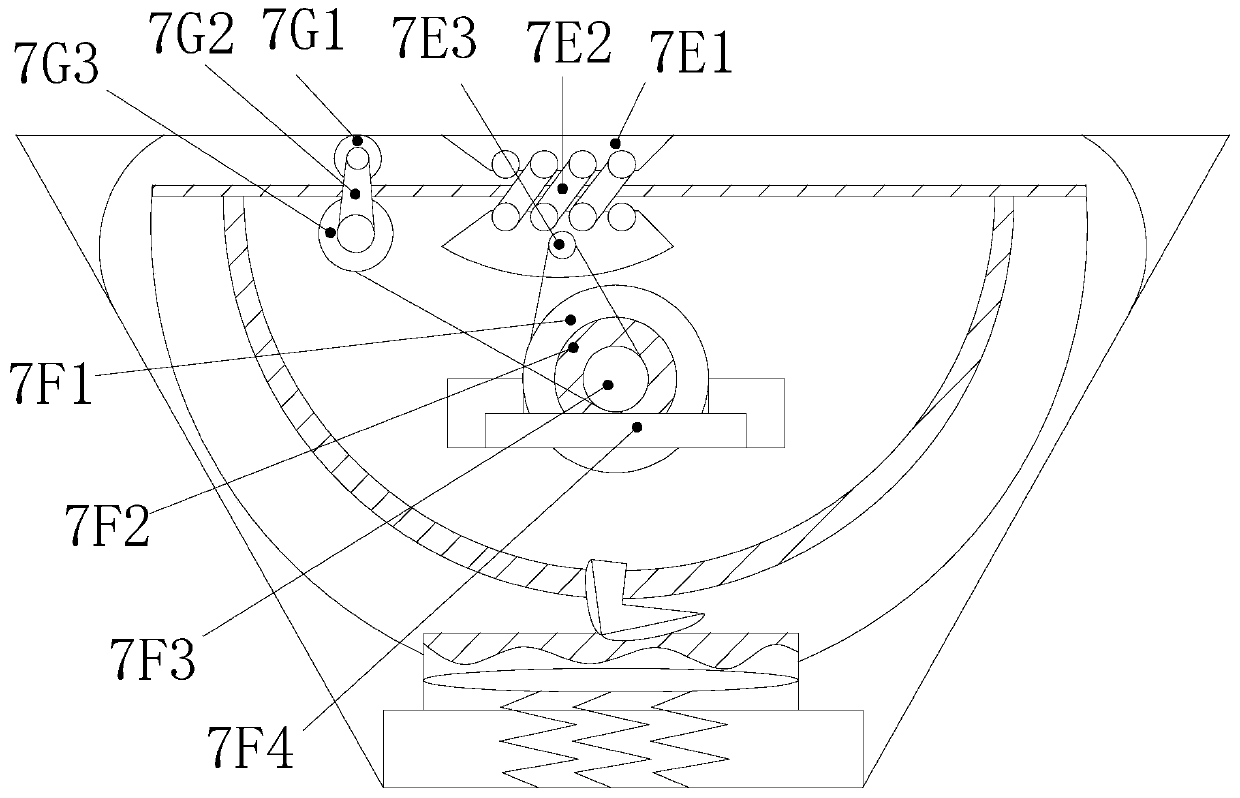

[0032] see Figure 1-Figure 7 , the present invention provides a kind of cooking equipment for absorbing core roller sieve shuttle evenly in the production process of sanitary napkins, its structure includes: shaft motor 1, conveyor belt groove 2, traction wheel disc 3, bearing seat 4, feeding roller rod 5. Arc cover plate 6, ladder groove roller shuttle mechanism 7, storage square box frame 8, described ladder groove roller shuttle mechanism 7 is installed on the front side of storage square box frame 8 and is on the same vertical plane, the arc The cover plate 6 is mechanically connected to the top of the ladder groove roller shuttle mechanism 7 through a hinge. The bearing seat 4 is provided with two and respectively nested on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com