A self-propelled channel steel derusting equipment

A self-propelled, channel steel technology, applied to mechanical equipment, liquid cleaning methods, instruments, etc., can solve the problems of cumbersome operation, time-consuming rust removal and washing, etc., and achieve the effect of simple operation and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

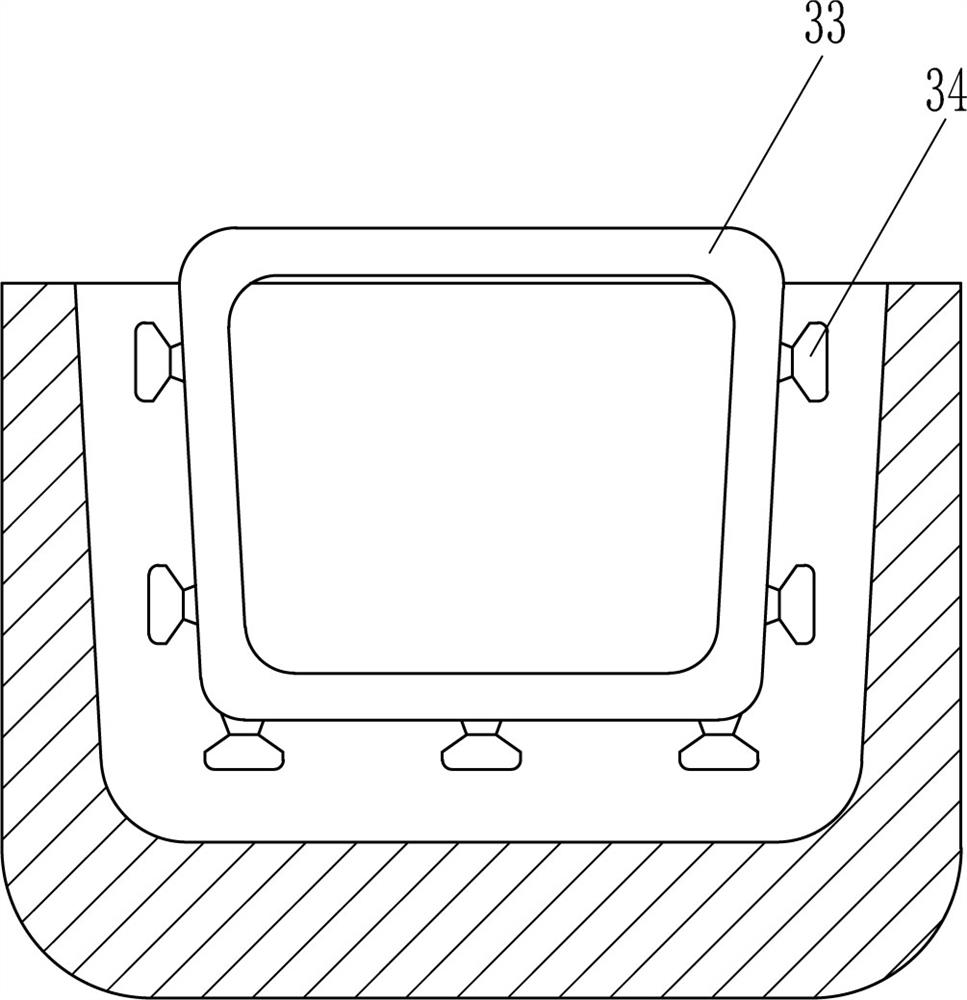

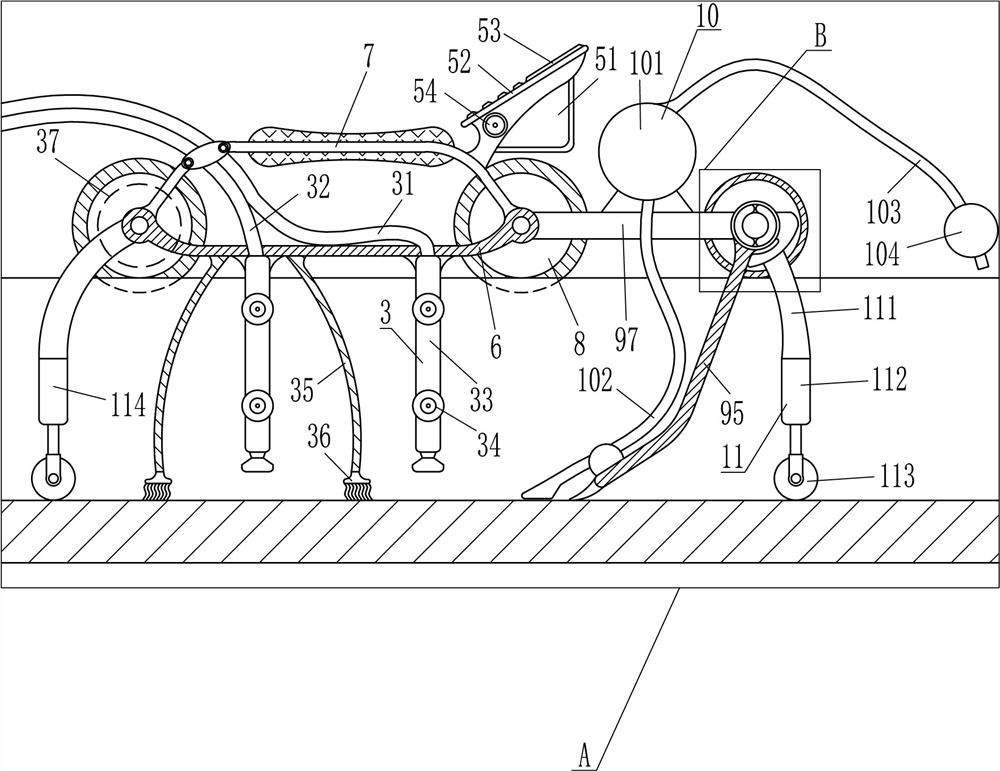

[0025] A self-propelled channel steel derusting equipment, see figure 1 , figure 2 and Figure 5 , including a frame 1, a booster mechanism 2, a spray mechanism 3, a suspension 6, a pull rod 7 and a guide wheel 8, the top of the frame 1 is provided with a booster mechanism 2 and a sprinkler mechanism 3, and the booster mechanism 2 is used for water and derusting agent into the spraying mechanism 3, the spraying mechanism 3 is used to spray water and derusting agent into the channel steel, the front and rear sides of the pull rod 7 are fixedly connected with suspensions 6, and the suspensions 6 on the front and rear sides rotate There are two guide wheels 8 for reducing friction.

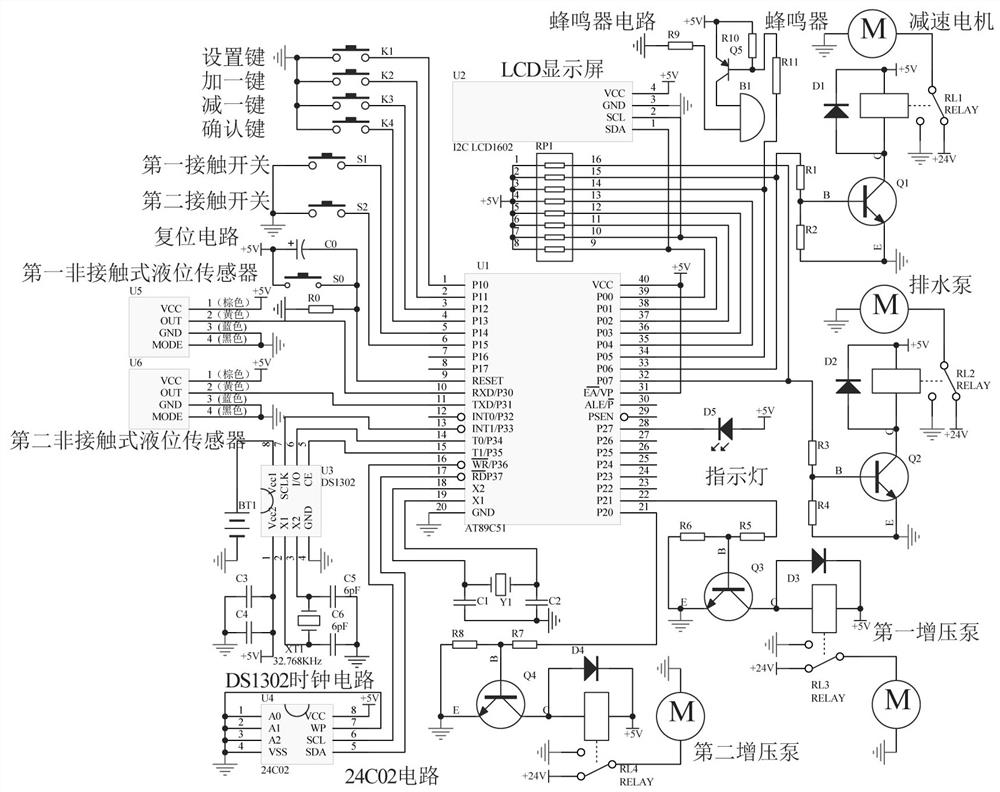

[0026] see figure 2 , Figure 6 and Figure 7 , also includes control module, setting key, plus one key, minus one key, confirmation key, LCD display 53 and buzzer 54, setting key, plus one key, minus one key, confirmation key, LCD display 53 and The buzzers 54 are electrically connected with...

Embodiment 2

[0033] This embodiment is on the basis of embodiment 1, see figure 2 and image 3 , also includes a wiper mechanism 9, the wiper mechanism 9 includes a rotating shaft 91, a rubber friction roller 92, a friction block 93, a connecting ring 94, a wiper blade 95, a limit block 96 and a mounting frame 97, two suspensions 6 The right side is fixedly connected with a mounting frame 97, the right part of the mounting frame 97 is rotatably connected with a rotating shaft 91, a rubber friction roller 92 is installed on the rotating shaft 91, a connecting ring 94 is provided on the rotating shaft 91, and two friction blocks are arranged on the inside of the connecting ring 94 93. The two friction blocks 93 are arc-shaped, and both friction blocks 93 are in contact with the rotating shaft 91. The right side of the mounting bracket 97 is connected with a limit block 96, and the connecting ring 94 is connected with a wiper blade 95.

[0034] When the guide wheel 8 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com