Steel structural component convenient to disassemble and assemble

A technology of steel structures and components, which is applied in the direction of building construction and construction, and can solve problems such as difficult disassembly and assembly of beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

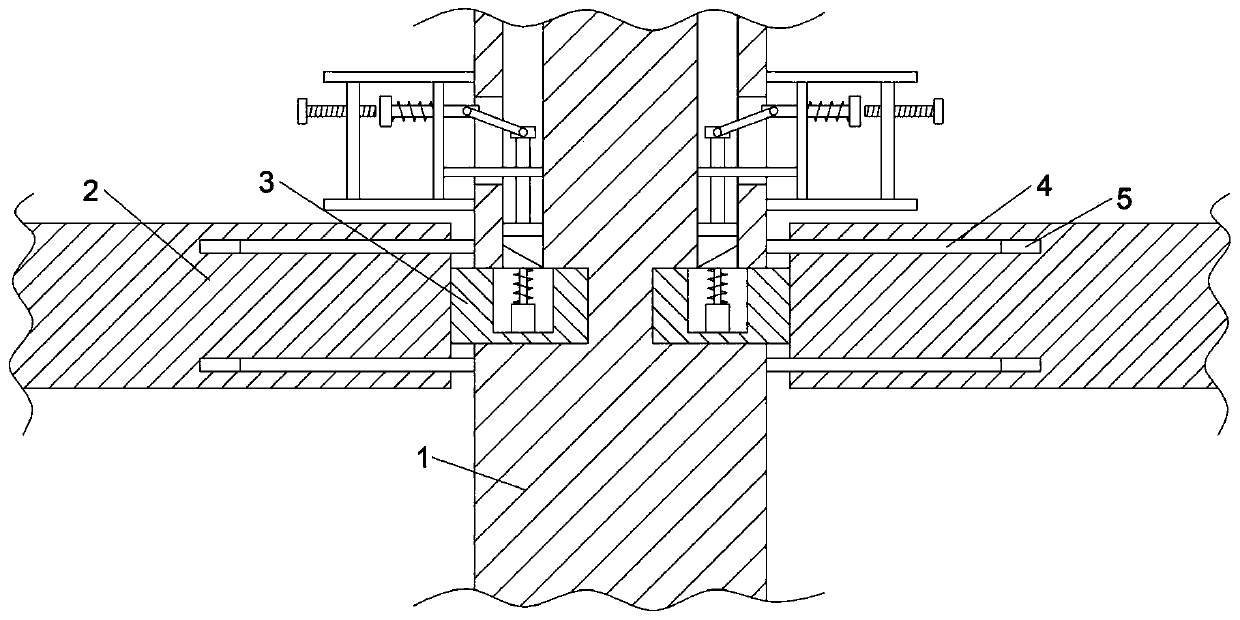

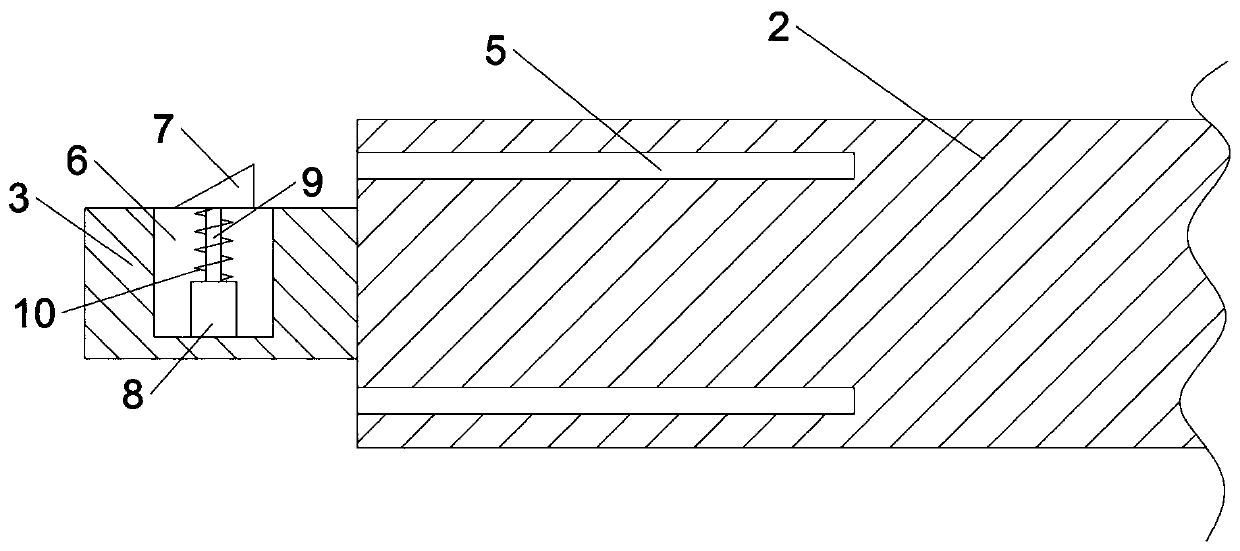

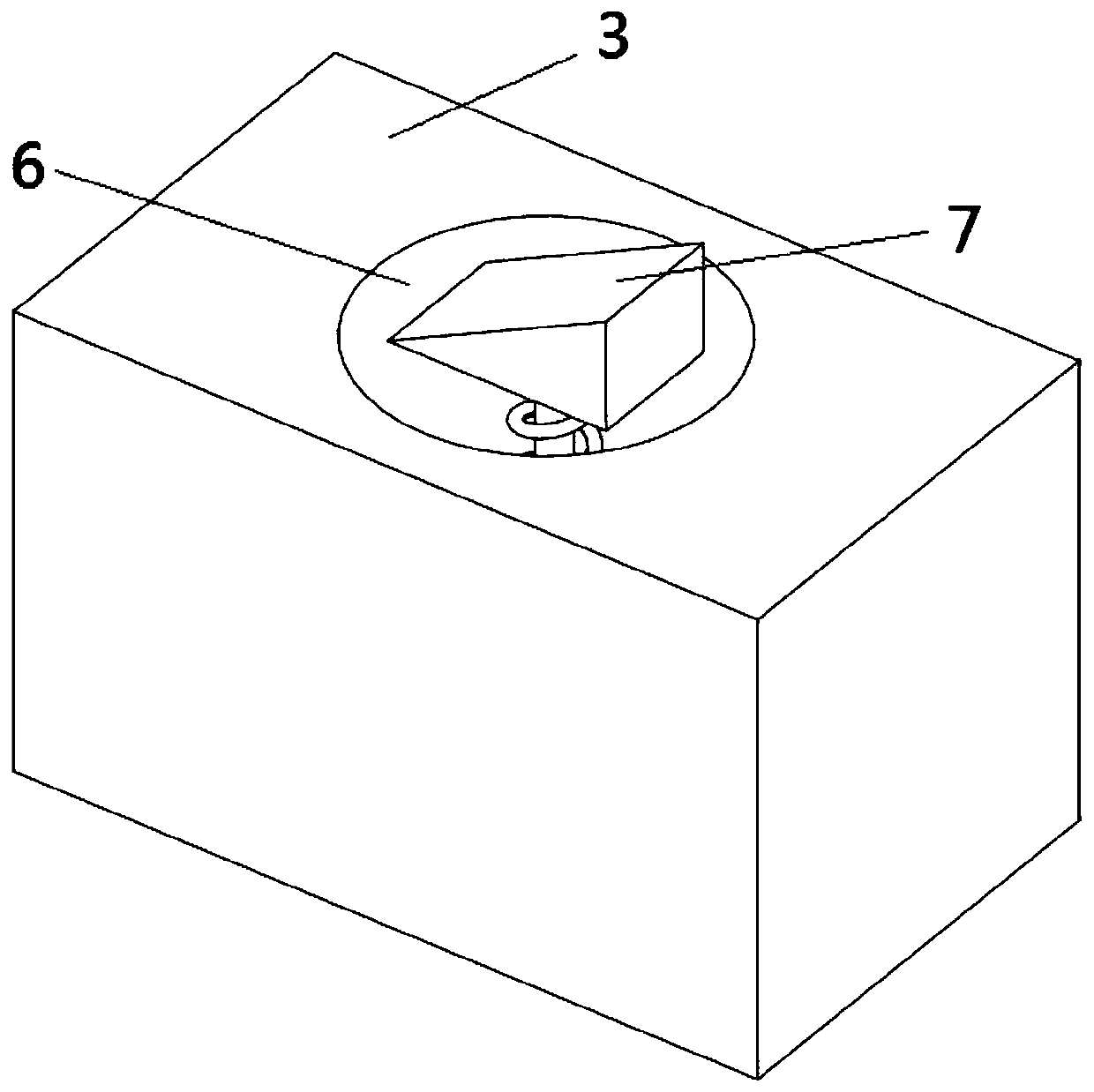

[0026] Refer to attached Figure 1-5 , this embodiment provides a steel structural member that is easy to assemble and disassemble, including a pillar 1 and two sets of symmetrical beams 2, and the pillars 1 and the beams 2 are made of steel. In addition, the pillar 1 is provided with two sets of slots 11 corresponding to the crossbeam 2, and a positioning assembly for positioning the crossbeam 2 is provided between the pillar 1 and the crossbeam 2. There is a block 3 matching with the slot 11, the block 3 is provided with a limiting assembly for limiting the block 3, and the pillar 1 is also provided with a mounting hole 12, the The installation hole 12 communicates with the card slot 11, and the installation hole 12 is provided with a release assembly for releasing the limit assembly to the block 3; when the block 3 is inserted into the card slot 11 , said limit assembly automatically clamps the clamping block 3 in the clamping slot 11 .

[0027] Specifically, the position...

Embodiment 2

[0033] Refer to attached Figure 6 , this embodiment is improved on the basis of embodiment 1, specifically, the second fixed block 31 is fixed on the beam 2, and the second fixed block 31 is rotatably connected with one end of the telescopic rod 30, The other end of the telescopic rod 30 is rotatably connected to the second connecting block 29, the second connecting block 29 is fixed with a limit rod 28, the pillar 1 is fixed with a first fixed block 26, and the The first fixing block 26 is provided with a limiting hole 27 matched with the limiting rod 28 . By rotating and elongating the telescopic rod 30 , the limit rod 28 can be inserted into the limit hole 27 , so as to play the role of auxiliary support and fixation of the beam 2 .

[0034] To sum up, the steel structural member provided by the embodiment of the present invention is provided with a positioning assembly with a positioning rod 4 and a positioning hole 5 between the pillar 1 and the crossbeam 2, and the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com