A method for evaluating the effect of repairing pipelines using epoxy steel sleeves

A technology using epoxy steel and evaluation methods, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, instruments, etc., to achieve the effect of improving the management level

Active Publication Date: 2022-07-05

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the above-mentioned shortcomings of the prior art, provide a method for evaluating the effect of repairing pipelines using epoxy steel sleeves, and solve the problem of how to detect the effectiveness of the product when pipeline managers use epoxy steel sleeves to repair pipelines. To ensure the effectiveness and reliability of repairing in-service pipelines with defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0146] In order to more clearly illustrate the detection and evaluation method of the epoxy steel sleeve repair technology of the present invention, the following examples are given.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

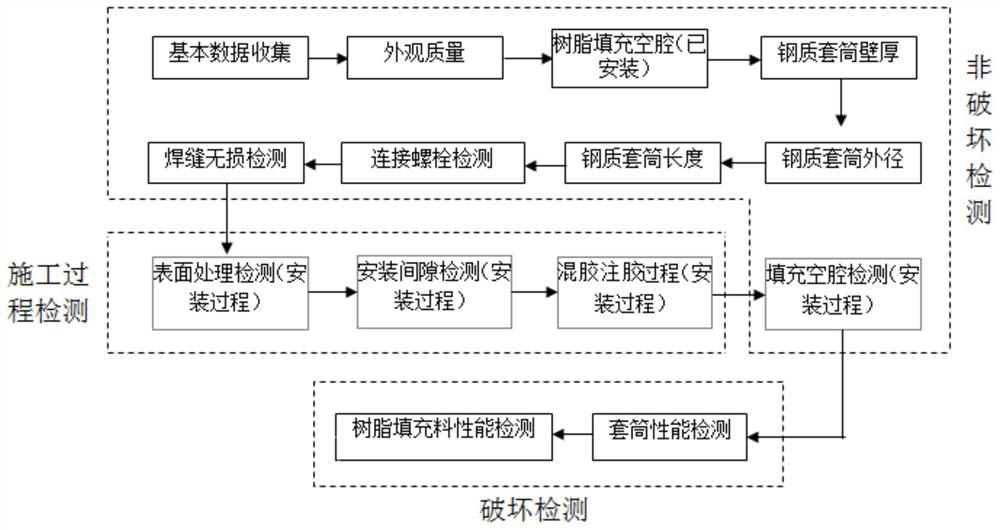

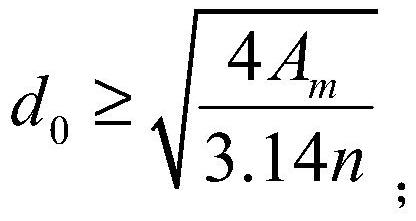

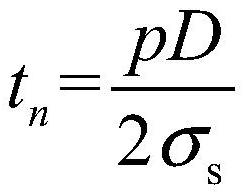

The invention discloses a method for evaluating the effect of repairing pipelines by using an epoxy steel sleeve, including the following contents: 1. Determine the detection content according to three parts: repair design parameters, repair material itself and construction quality, wherein the repair material itself includes the sleeve Material performance and resin filling material performance are two parts; 2. Test each test item in step 1 one by one, which is divided into non-destructive testing, destructive testing and testing during construction; 3. Test in step 2 After the project inspection is completed, the inspection results are evaluated. If the evaluation results of all projects are qualified, the repair effect of the epoxy steel sleeve is qualified, otherwise, it is unqualified. It solves the problem of how to check the validity and reliability of the product when the pipeline manager uses the epoxy steel sleeve to repair the pipeline, so as to ensure the validity and reliability of the repair of the defective pipeline in service.

Description

technical field [0001] The invention belongs to the field of pipeline repair, and relates to a method for evaluating the effect of repairing pipelines by using an epoxy steel sleeve. Background technique [0002] Epoxy steel sleeve repair technology is a pipeline repair technology invented and first used by British Gas in the 1970s. It is mainly used for defect repair of oil and gas pipelines. This technology is an improved and developed product based on the A-type sleeve. The outer steel sleeve usually has a certain gap from the steel pipe surface, and then the gap is filled with high-strength epoxy resin material. After the filling material is cured, it is connected with the outer sleeve. The joint action transmits stress and plays the role of defect reinforcement and repair. Because the epoxy steel sleeve repair technology does not need to stop the pipeline and directly fire on the pipe wall, there is no risk of welding penetration and welding cracks caused by hot fire. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01D21/02F16L55/175

CPCG01D21/02F16L55/175

Inventor 任俊杰马卫锋王珂罗金恒聂海亮曹俊赵新伟

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com