A method for judging the signal of the inner detection line of the three-axis magnetic flux leakage in a pipeline depression

A detection line and magnetic flux leakage technology, which is applied in the field of measuring magnetic variables and pipeline systems, can solve problems such as not given, and achieve the effects of simple judgment, improved integrity management level, and improved ability to identify such defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment. This example is an on-the-spot industrial test done on a certain Φ720mm pipeline.

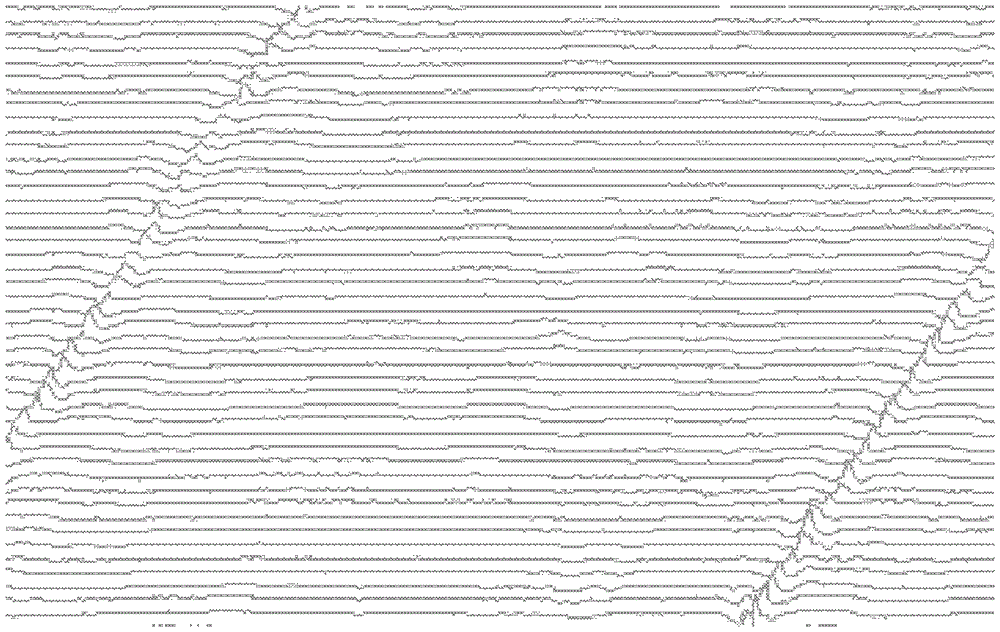

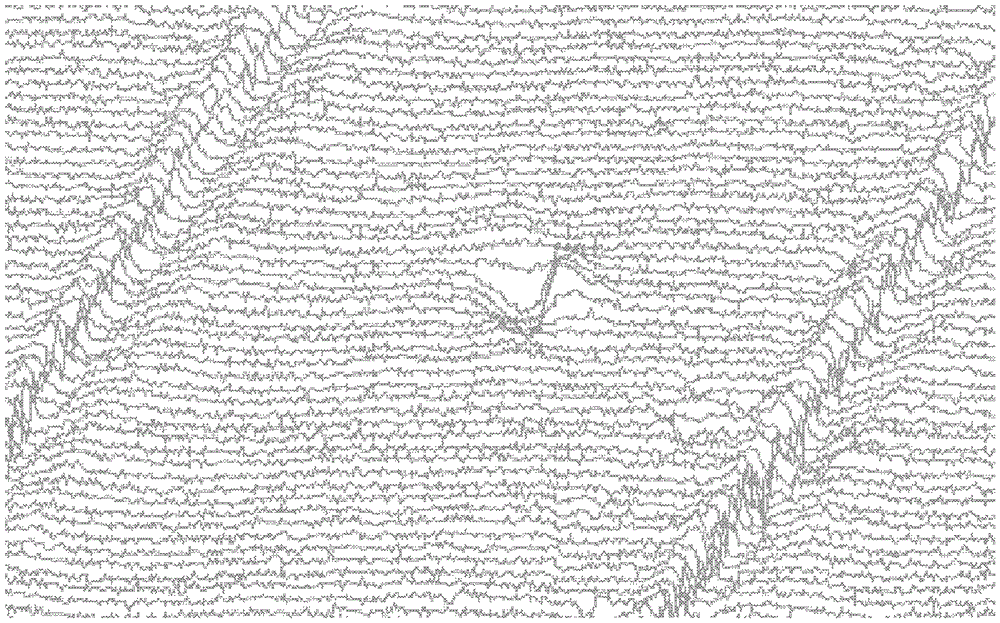

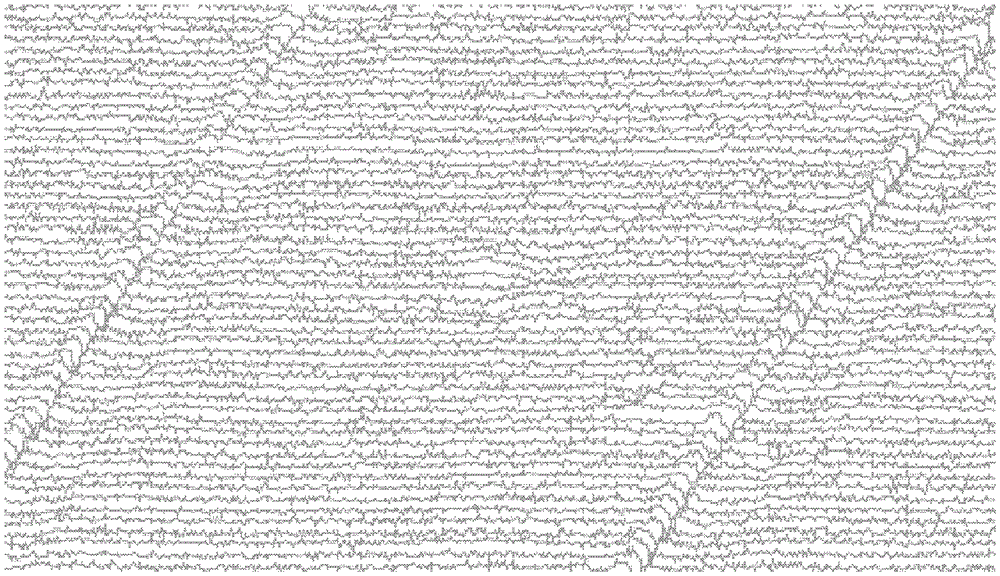

[0019] This example is the real defect feature on the pipeline and the three-axis high-definition magnetic flux leakage internal detection signal. For details, see Figure 1-Figure 3 .

[0020] It is a judging method according to the present invention, and the test sample is verified after the defect is cut off on the pipeline. There is a real defect on the pipeline, after the three-axis high-definition magnetic flux leakage internal inspection, it is as follows figure 1 The axial signal waveform diagram shown, such as figure 2 As shown in the radial signal waveform diagram, such as image 3 The horizontal signal waveform diagram is shown. The axial signal waveform diagram and the horizontal waveform diagram line signal are basically unchanged, and the signal amplitude change is less than 3mt; the radial signal is a bidirectional pulse wave, the signal height amplitude i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com