Special tool for embedding sealing ring in hydraulic pipe straight pipe

A technology for special tools and sealing rings, which is applied in the manufacture of tools, hand-held tools, etc., can solve the problems of affecting the sealing performance of sealing rings, laborious manual operation, inconvenient installation, etc., and achieve good sealing effect and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

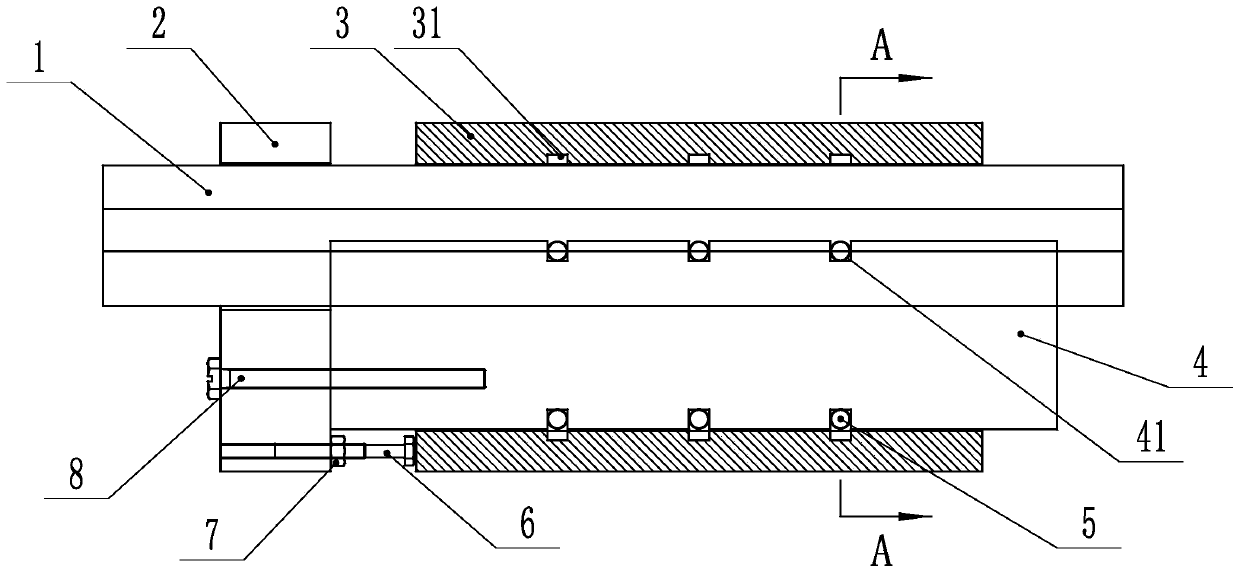

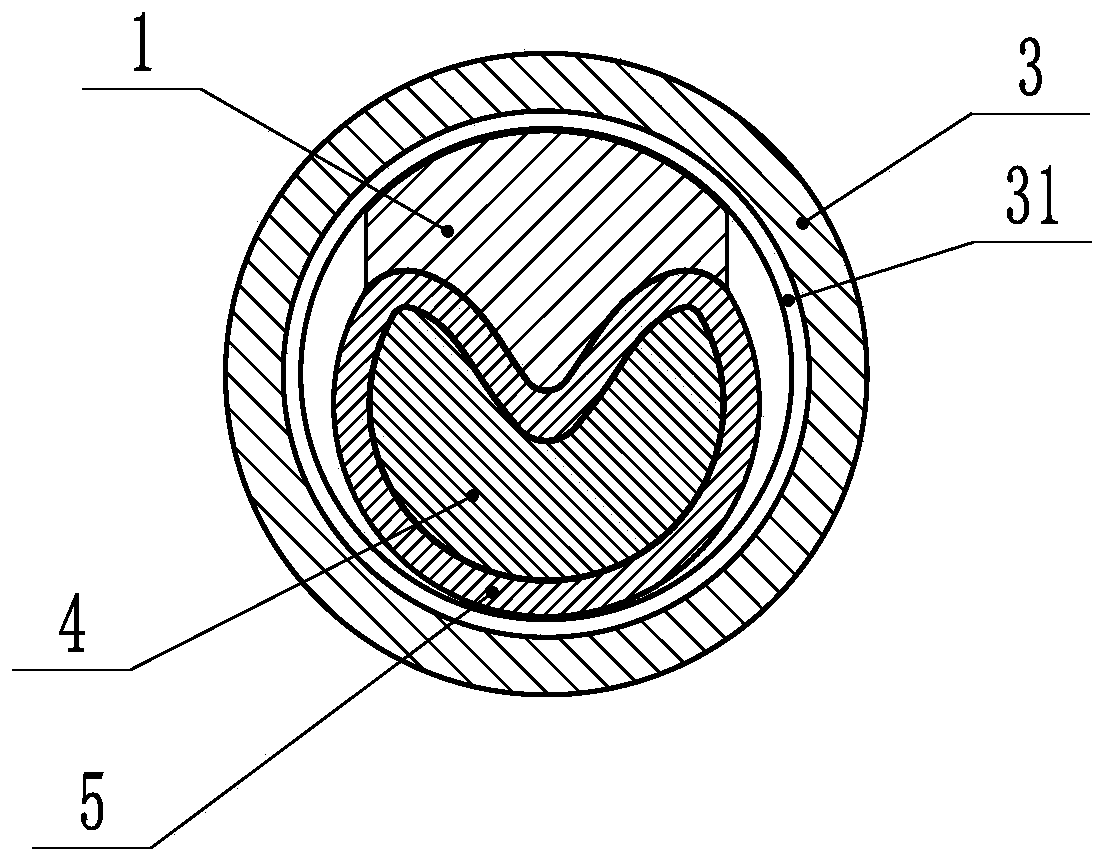

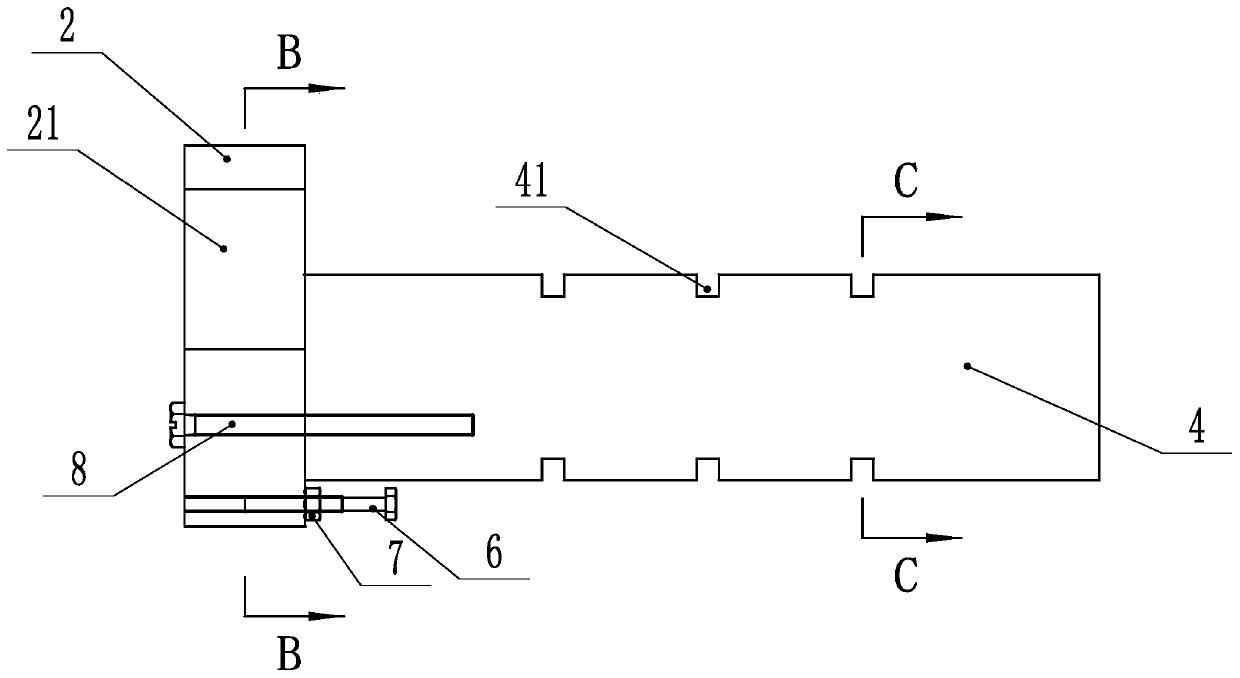

[0024] like Figure 1-8 As shown, a special tool for sealing rings embedded in hydraulic pipe straight pipes according to an embodiment of the present invention includes a main body 4 whose cross-section is crescent-shaped and the main body 4 is processed with track grooves on the crescent-shaped cross-section 41. The left side of the main body 4 is fixedly connected to a base 2 through bolts 8. The base 2 is processed with a guide hole 21 in the upper half. The movable rod 1 is matched through the guide hole 21 and extends into the upper half of the main body 4. The sealing ring 5 is embedded in the track groove 41 under the extrusion of the movable rod 1; wherein, the depth of the track groove 41 is greater than the thickness of the sealing ring 5, the lower part of the track groove 41 is a part of the arc, and the upper part is a concave part 411; the movable rod 1 The lower part is the extrusion part 11, the extrusion part 11 is matched with the recessed part 411, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com