Composite stamping die

A technology of stamping dies and combined dies, applied in the field of stamping dies, can solve the problems of reducing replacement time, reducing production efficiency, personnel injuries, etc., and achieving the effect of improving work efficiency, reducing personnel injuries, and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

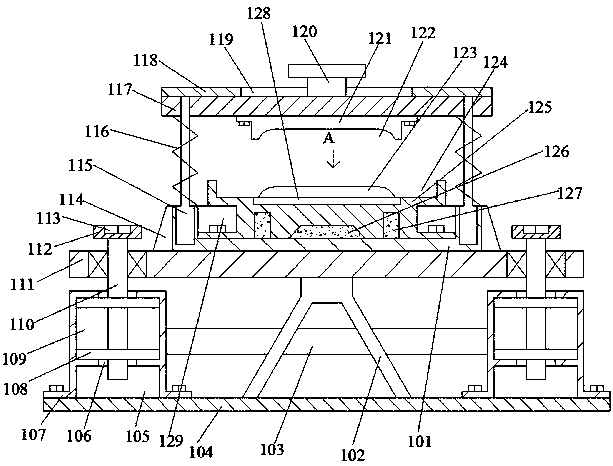

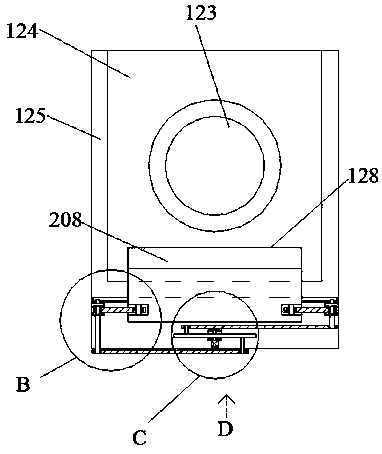

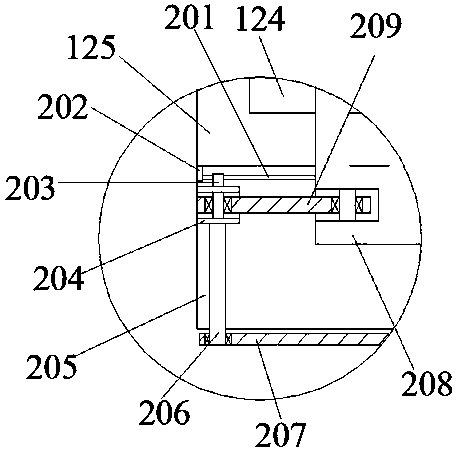

[0025] Such as Figure 1-Figure 6 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are consistent. A composite stamping die of the present invention includes a bottom plate 104, and several mounting devices for installing the mold are arranged above the bottom plate 104, and a combination of punching process is arranged in the mounting device. The mold device, the front of the combined mold device is provided with an automatic pop-up device for automatically popping up the workpiece, so that the above-mentioned device can be used to realize efficient stamping and automatic workpiece pop-up functions.

[0026] Beneficially, wherein, the installation device includes a solid box 107 that is fixedly connected with the bottom plate 104 by bolts, and a sliding cavity 109 with an opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com