Intermediate reheating steam power generation system

A power generation system and reheat steam technology, applied in steam generation, steam superheating, steam boilers, etc., can solve the problems of unit failure, high-temperature reheat steam distribution, etc., to reduce the overall layout and investment costs, and realize Safe and stable operation, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

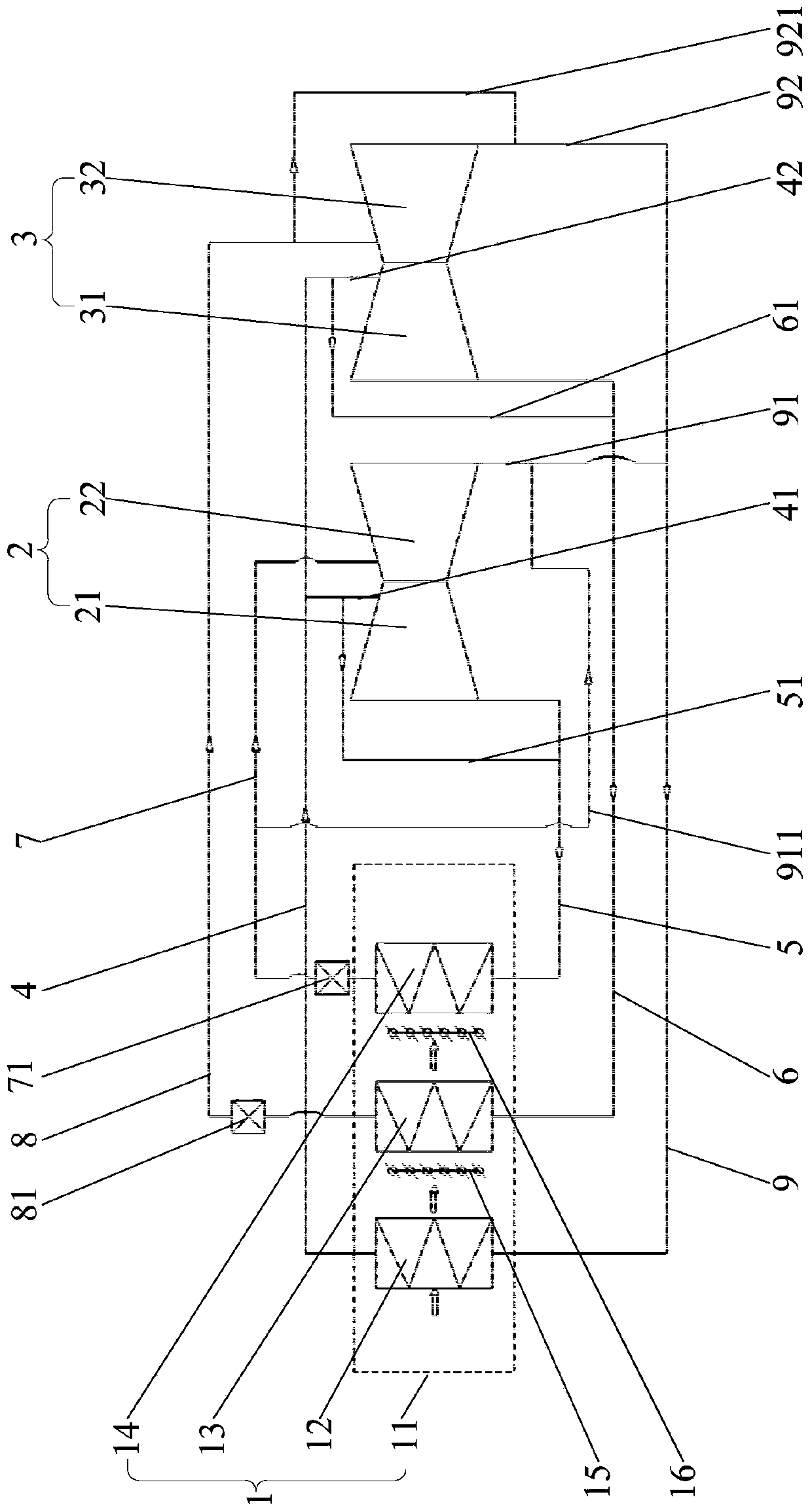

[0048] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the use of "high pressure" and "low pressure", "high temperature" and "low temperature" is only for the convenience of relative reference between groups of terms, and does not describe any specific limitation on the modified terms. The terms "first", "second" and so on are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance or implicitly specifying the number of indicated technical features. Therefore, the terms "first", " A second, etc. feature may explicitly or implicitly include one or more of these features.

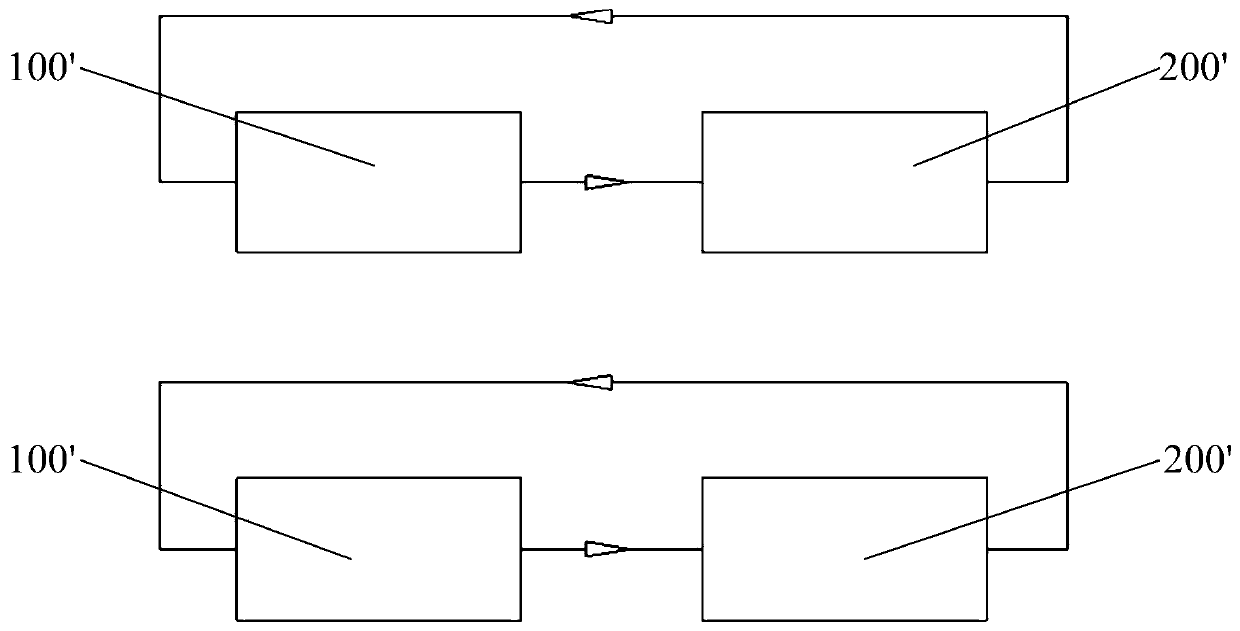

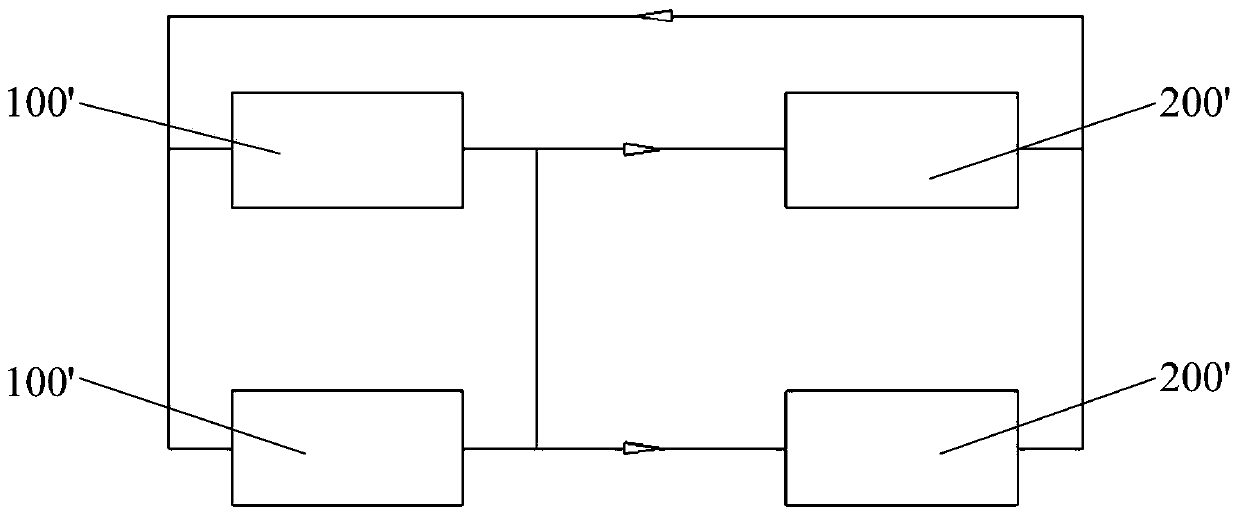

[0049] Such as image 3 As shown, the present invention provides an intermediate reheat steam power generation system, which includes a boiler 1, a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com