Novel liquid discharge device of coke oven coal gas

A liquid draining device and technology for coke oven gas, which are applied in combustible gas purification, combustible gas purification/reconstruction, petroleum industry, etc., can solve problems such as increasing the resistance of the gas system, affecting the gas-water-gas balance and heat balance, and accelerating the corrosion of gas pipelines. , to achieve safe and stable operation, reduce equipment operating costs, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

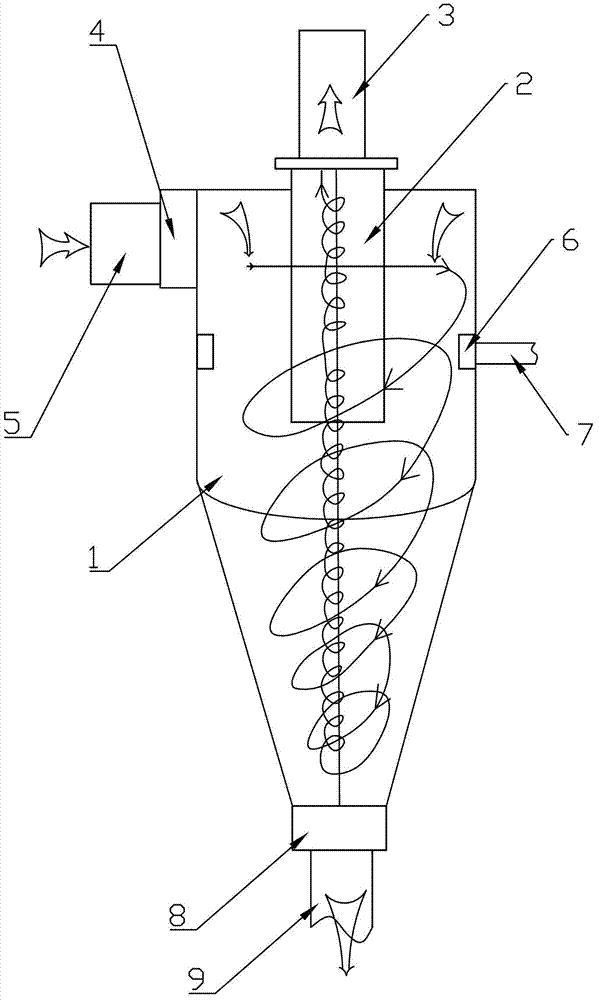

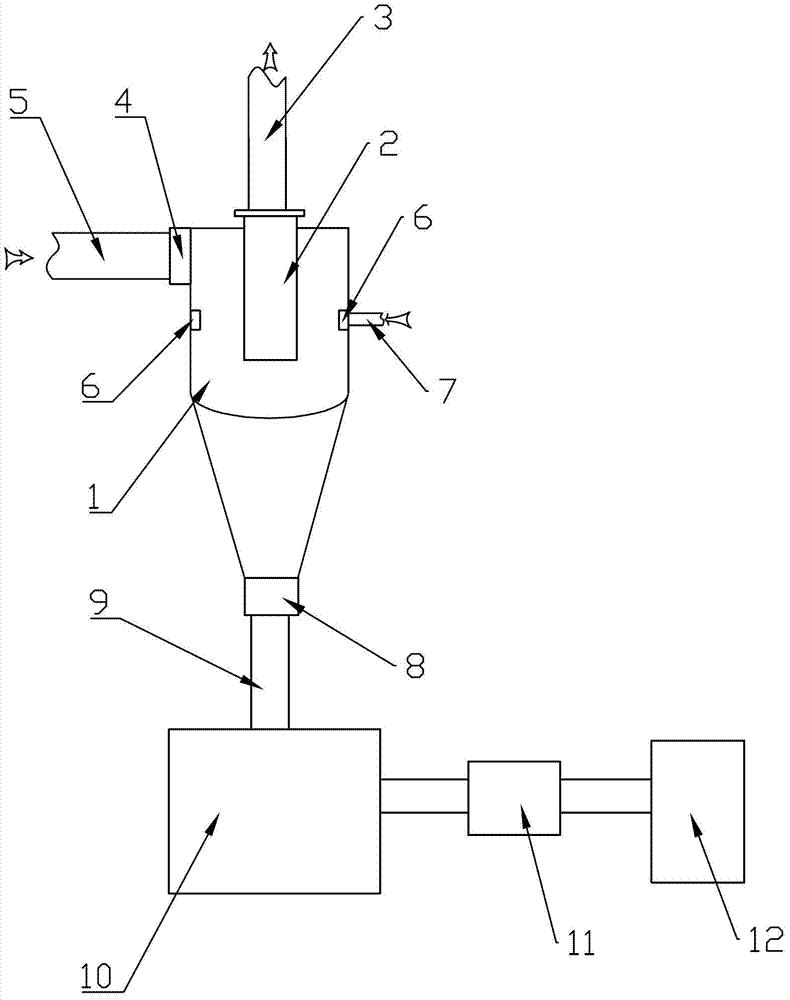

[0015] Such as figure 1 As shown, the present invention is a new coke oven gas liquid discharge device, which includes a conical cylinder 1, the upper end of the cylindrical part of the conical cylinder 1 is provided with an exhaust pipe 2, and the upper end of the exhaust pipe 2 is connected to The gas output pipe 3 has a lower end extending into the inside of the conical cylinder 1; the upper end of the cylindrical part of the conical cylinder 1 is provided with an air inlet 4 along the tangential direction, and the air inlet 4 is connected to the coke. The gas pipeline 5 of the furnace; the inner wall of the cylindrical part of the conical cylinder is provided with a circulating ammonia automatic spraying device 6, and the circulating ammonia automatic spraying device 6 is connected to an external circulating ammonia pipeline 7; the conical cylinder 1 The bottom conical part of the bottom is provided with a sewage outlet 8, and the sewage outlet 8 is connected to the underg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com