Molding device

A sub-mold and heat transfer technology, applied in the field of forming devices, can solve the problems of reduced production efficiency, increased sub-mold replacement time ratio, etc., and achieves the effect of increasing temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

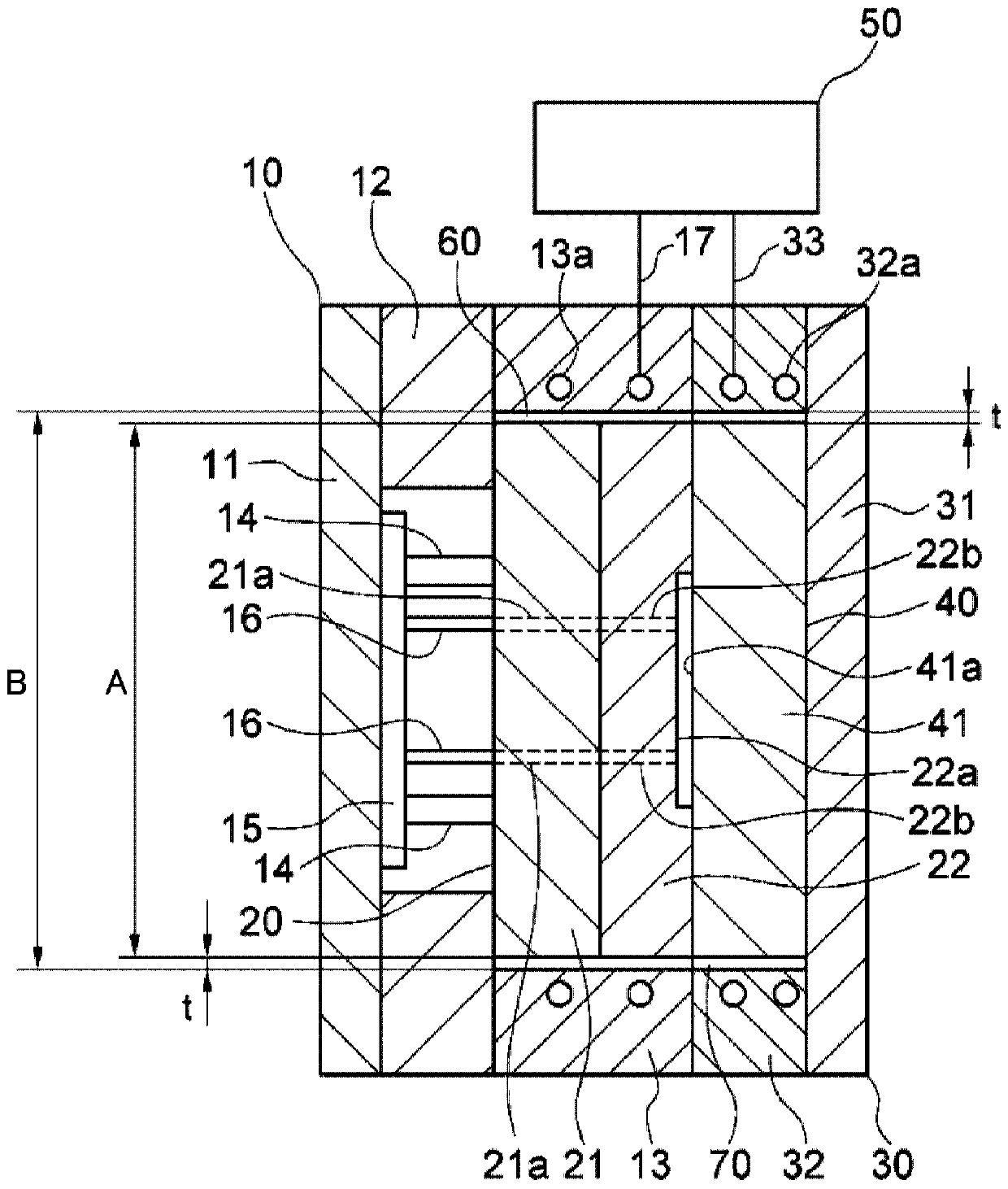

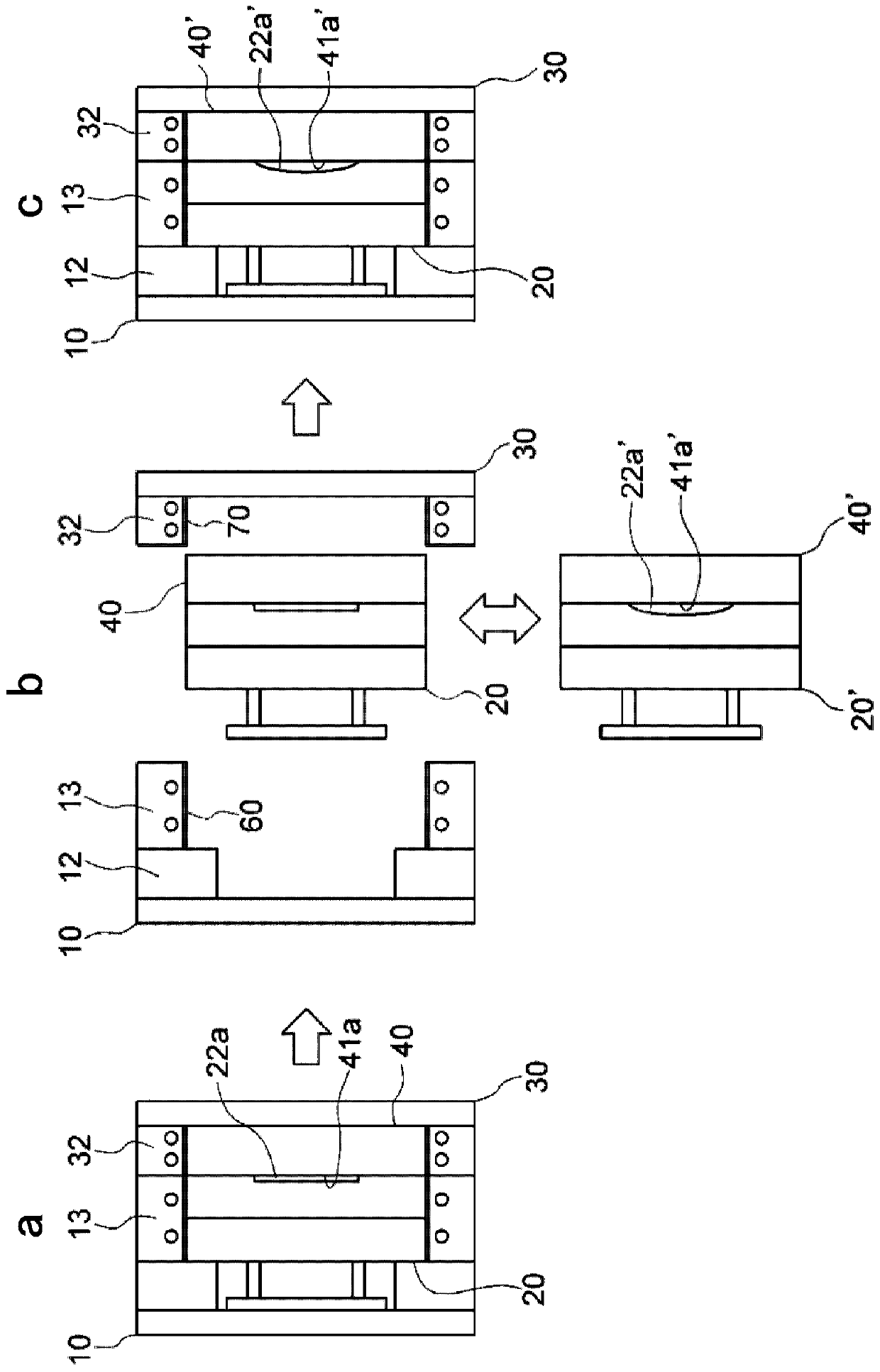

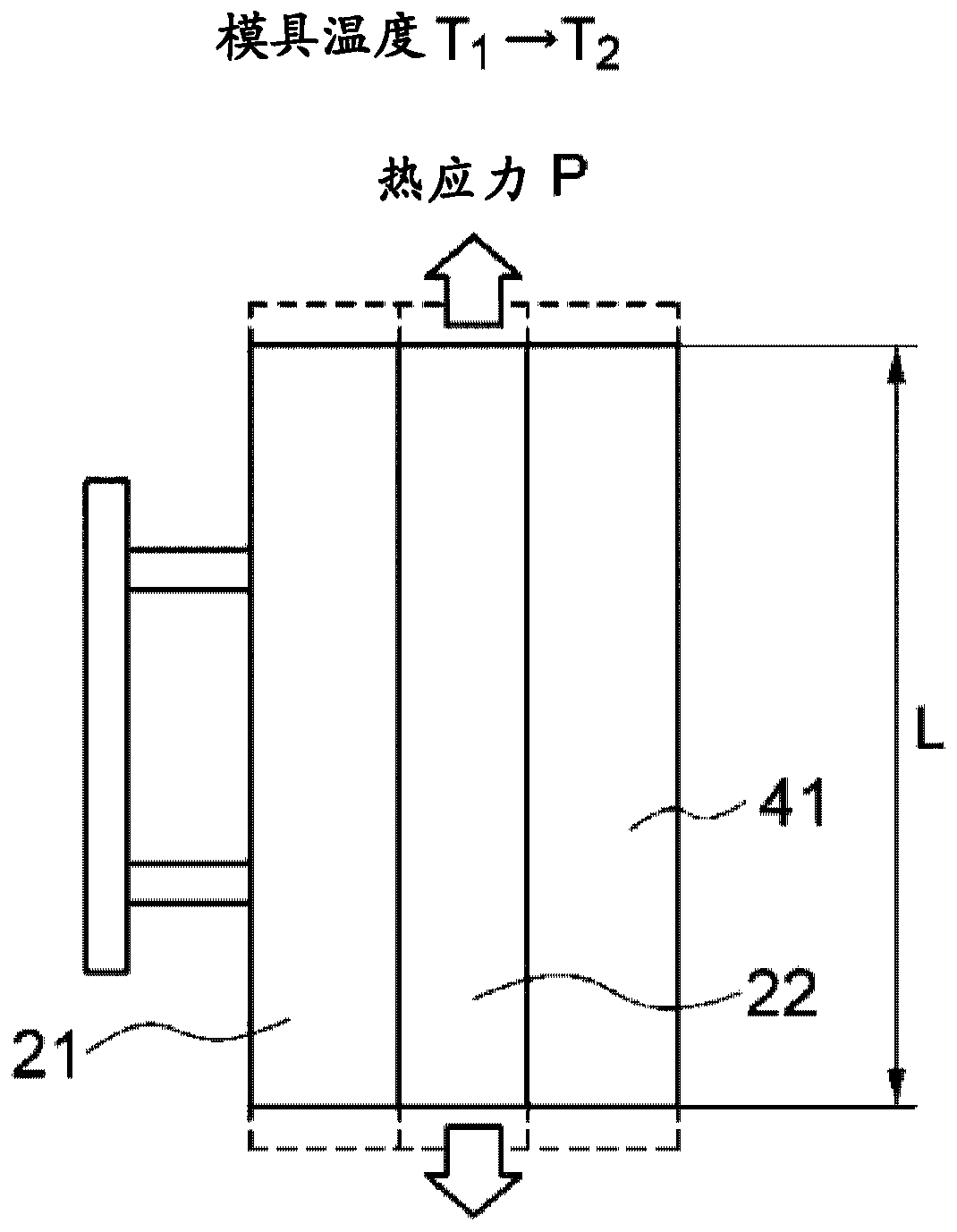

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 1A It is a schematic sectional view of the molding apparatus of this embodiment. The molding device has a fixed-side master mold 10 , a fixed-side sub-die 20 , a movable-side master mold 30 , a movable-side sub-die 40 , a temperature adjustment unit 50 , a fixed-side elastic member 60 , and a movable-side elastic member 70 . The master mold is composed of the fixed-side master mold 10 and the movable-side master mold 30, and the sub-mould is composed of the fixed-side sub-mould 20 and the movable-side sub-mould 40. The fixed-side elastic member 60 and the movable-side elastic member 70 are capable of elastic deformation. heat transfer components.

[0031] The fixed-side master mold 10 made of steel has a fixed-side receiving plate 11 , a first frame body 12 mounted on the fixed-side receiving plate 11 , and a second frame body 13 mounted on the first frame body 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com