An integrated honeycomb flue gas denitrification catalyst structure

A denitrification catalyst and honeycomb technology, which is applied in the field of integrated honeycomb flue gas denitrification catalyst structure, can solve the problems of catalyst reaction efficiency decline, catalyst installation and replacement difficulty, and poor controllability of the operation process, so as to improve installation, replacement and flexible use The effect of improving the stability and continuity of use, reducing the cost of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

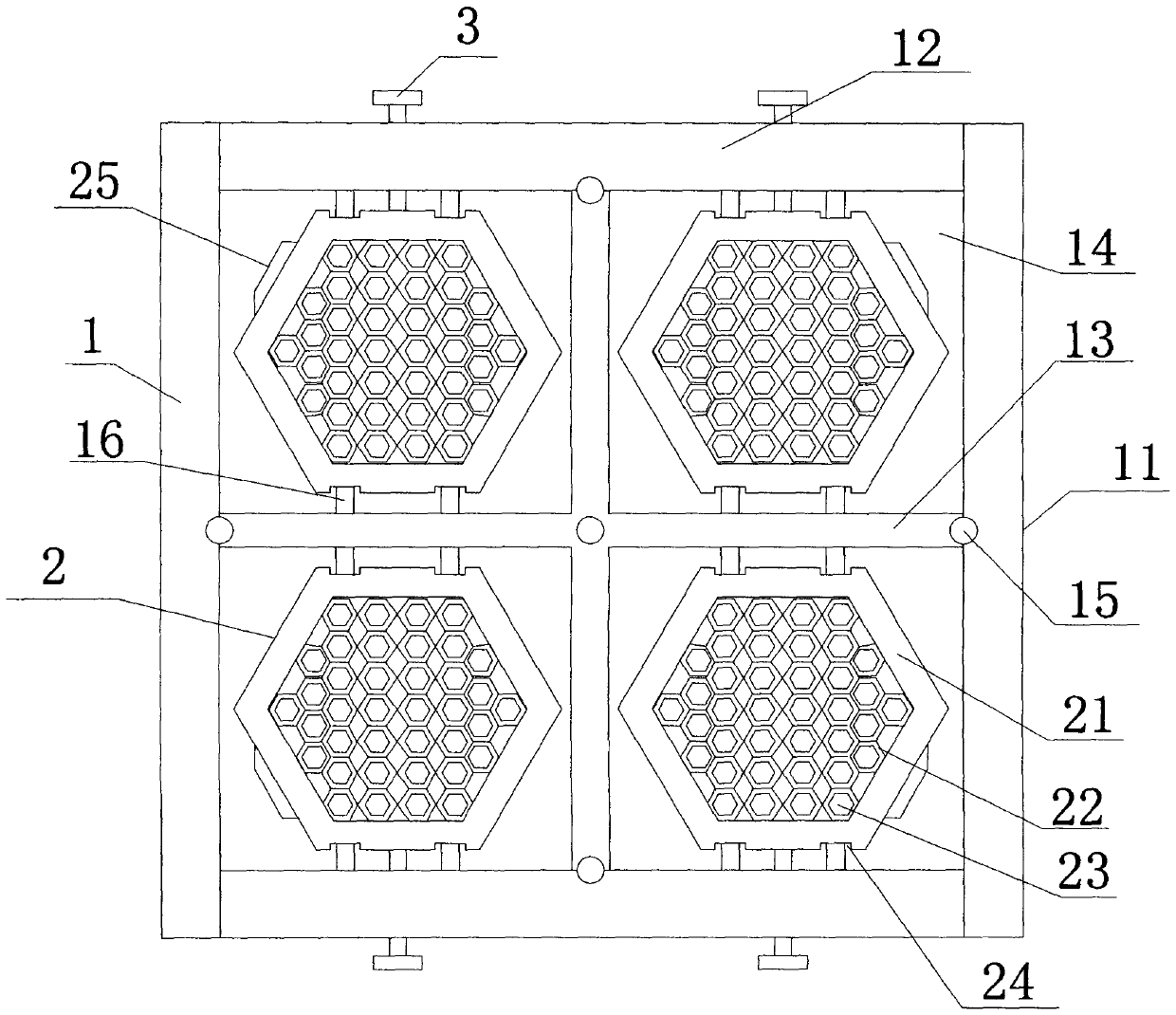

[0012] Such as figure 1 The integrated honeycomb type flue gas denitration catalyst structure includes a positioning frame 1 and a catalyst frame 2, wherein the positioning frame 1 includes a column 11, a beam 12, and a partition 13, and the column 11 and the beam 12 are connected and connected first in sequence. To form the working chamber 14 of the rectangular space frame structure, at least two partitions 13 are distributed in a "cross" shape, and the working chambers 14 are equally divided. The intersections of the partitions 13 and the intersections of the partitions 13 and the columns 11 and the beams 12 There are also circulating cooling pipes 15 at the positions, and at least four positioning pulleys 16 are evenly distributed on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com