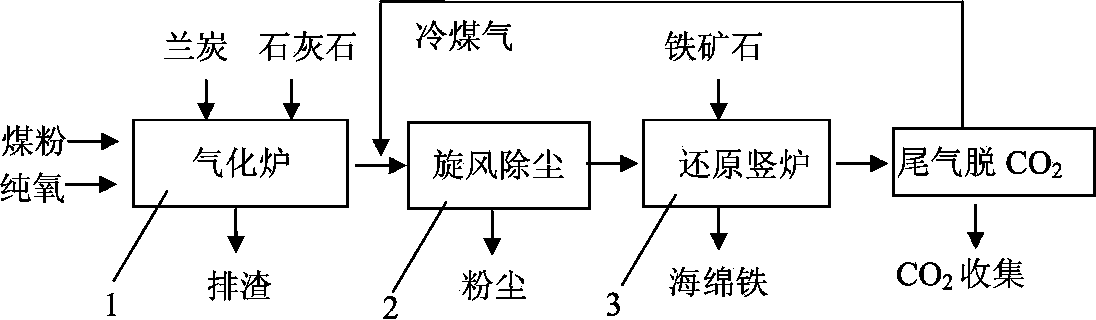

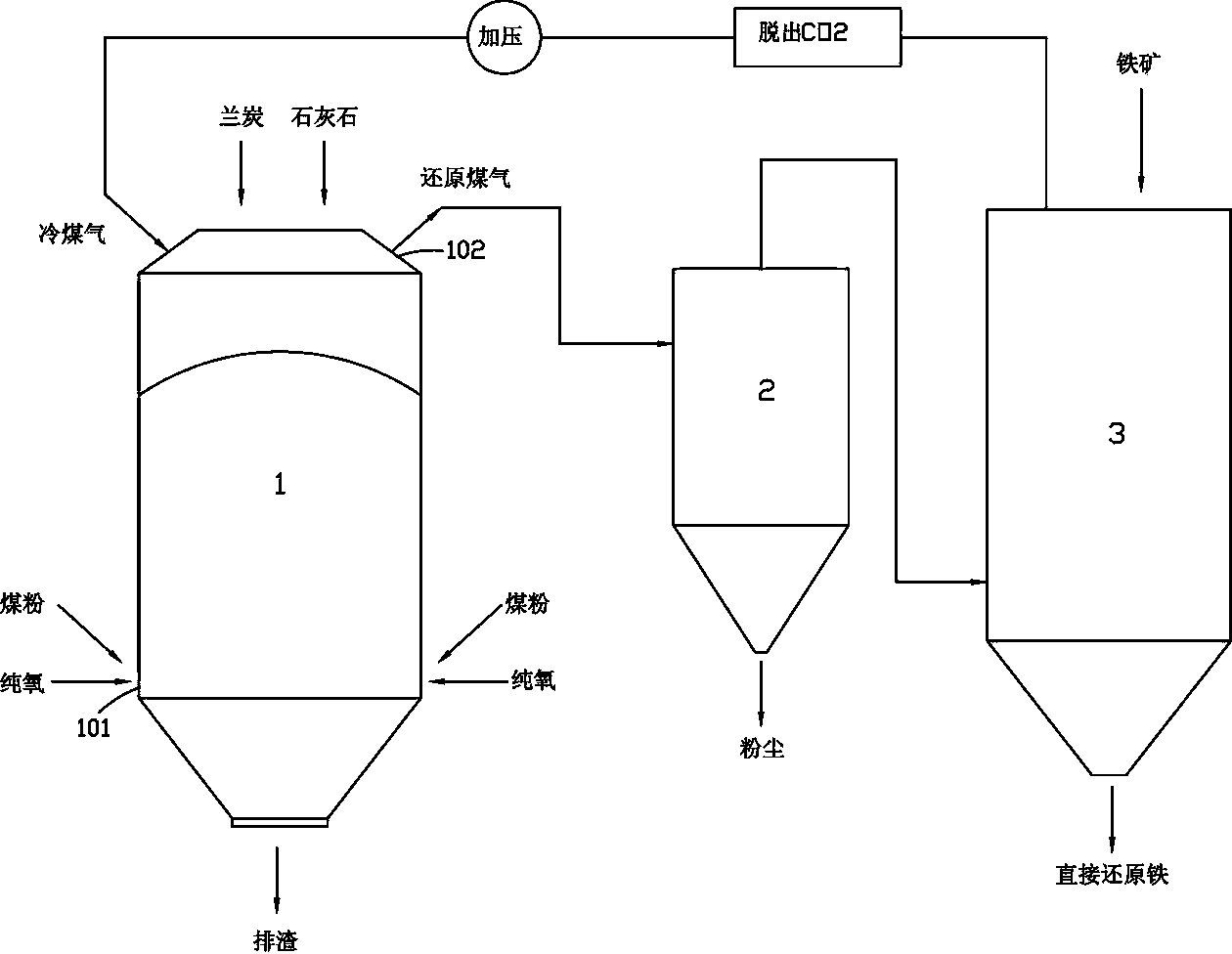

Process for producing direct reduced iron (DRI) by carrying out pure oxygen gasification on semicoke

A technology for reducing iron and semi-coke, applied in the direction of reducing gas emissions, furnace types, furnaces, etc., can solve the problems of difficulty in meeting the requirements of shaft furnace direct reduction of iron, uneconomical, complicated processes, etc., and achieve improved energy utilization , Avoid sintering process, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] See Table 1, Table 2 and Table 3 for the main components of the semi-coke raw material used in the production of direct reduced iron, pulverized coal for injection and iron ore, respectively. Oxygen with a purity of 99.6% is used as the gasification agent.

[0065] Table 1 Main components of semi-coke, %

[0066] Element

[0067] Table 2 Main components of pulverized coal injection, %

[0068] Element

[0069] Table 3 Main components of iron ore, %

[0070] Element

[0071] Pure oxygen is injected into the semi-coke gasifier, and the theoretical combustion zone temperature in the turning zone is greater than 2000°C, where the semi-coke and the injected coal powder are burned, and the temperature of the generated gas reaches the furnace top is about 1200°C. The composition of the gas is shown in Table 4 .

[0072] Table 4 Top gas composition of blue charcoal gas furnace, %

[0073] Element

[0074] Shaft Furnace Gas Removal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com