fire shutter door

A rolling shutter door, a pair of technology, applied in the direction of windows/doors, door/window protection devices, shutters/movable grilles, etc. Great use stability, easy and labor-saving position adjustment process, time-saving and labor-saving effects during transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

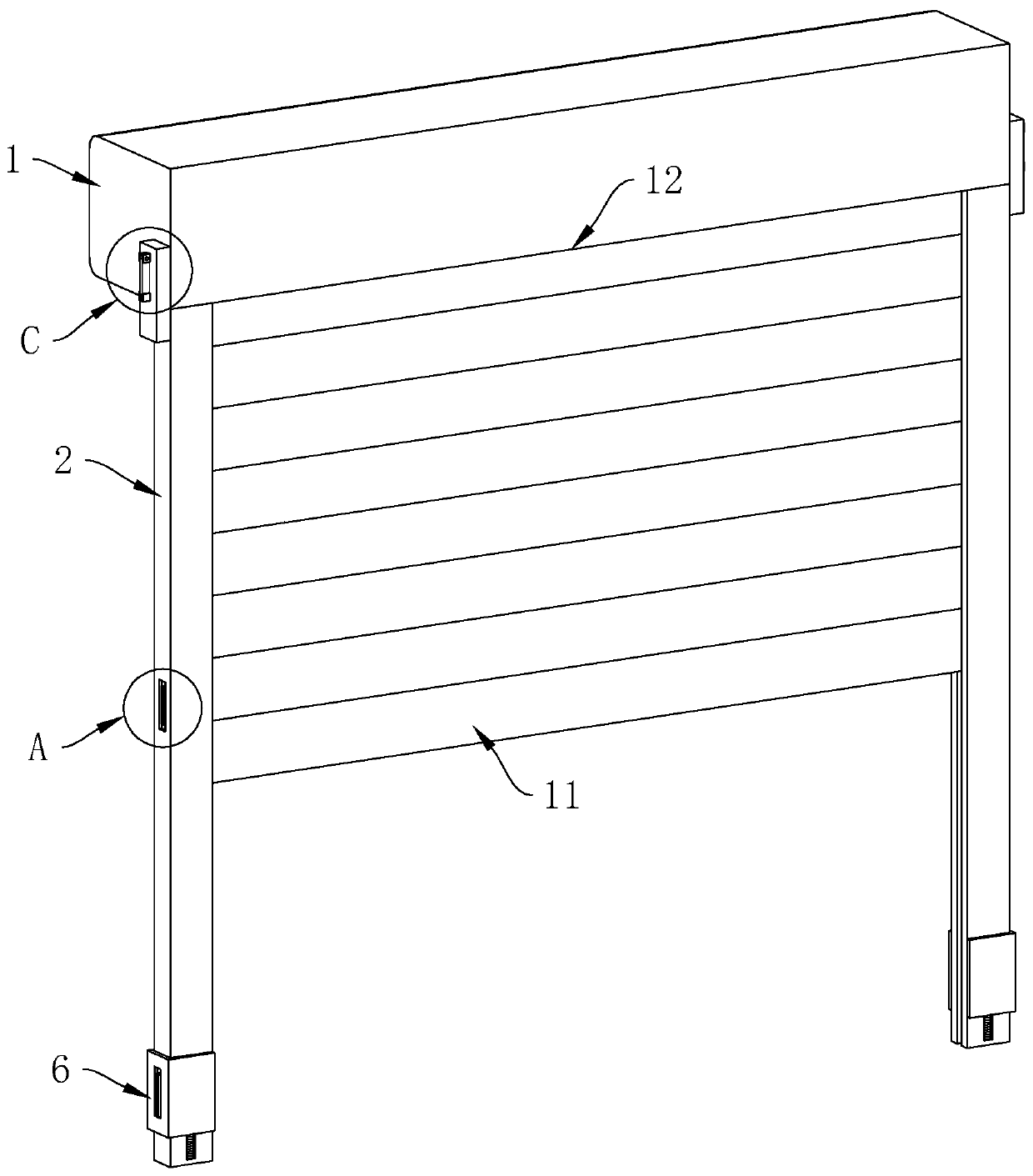

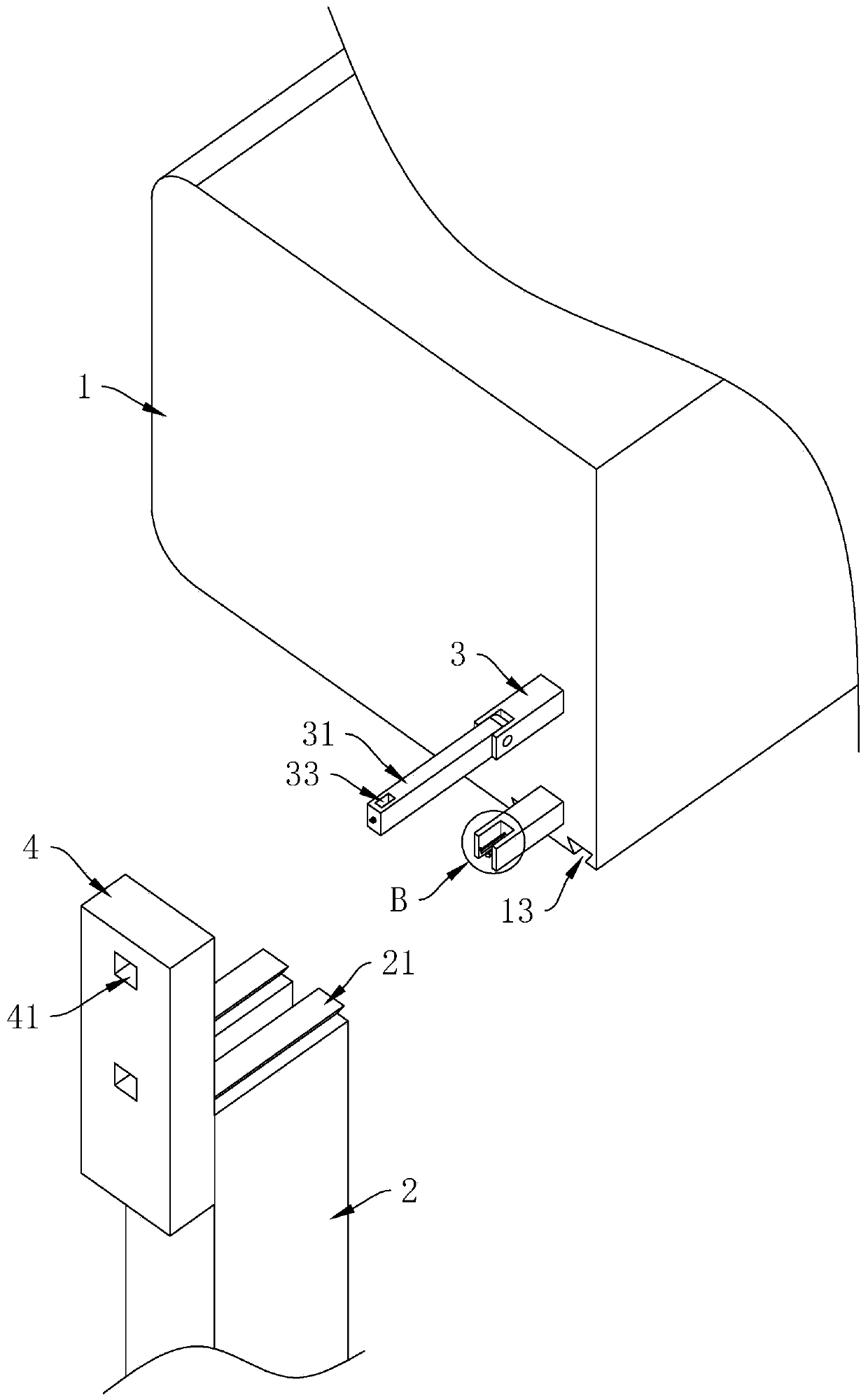

[0044] Embodiment 1: as figure 1 As shown, a fire shutter door includes a box body 1, and a reel (not shown in the figure) and a motor (not shown in the figure) for controlling the rotation of the reel are arranged inside the box body 1. A curtain 11 is wound on the reel, and a through hole 12 for passing the curtain 11 is provided on one side of the lower end surface of the box body 1 .

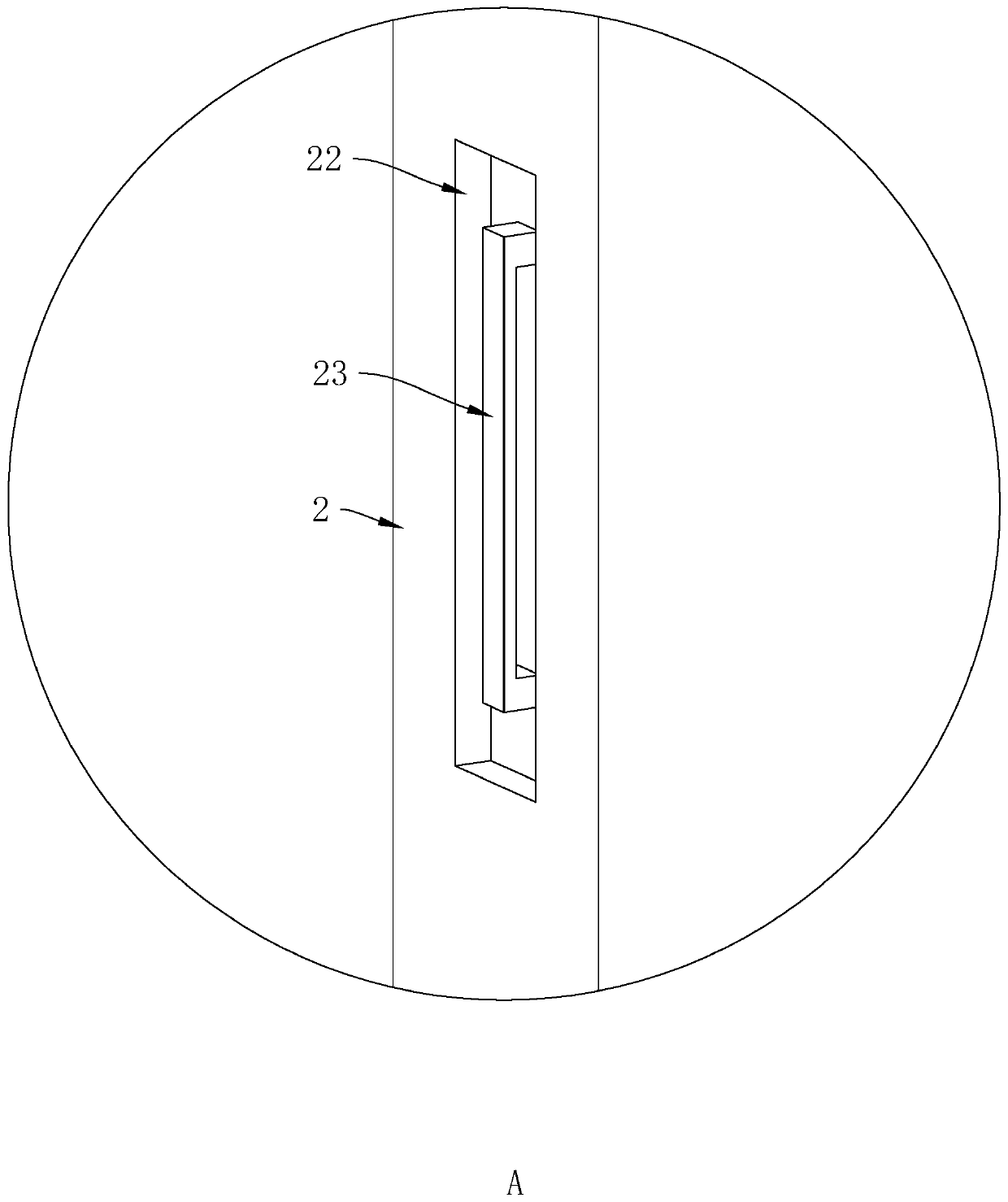

[0045] Such as figure 1 As shown, guide rails 2 are vertically arranged on the lower end surfaces of both ends of the box body 1, and the guide rails 2 are located on both sides of the through hole 12, and the guide rails 2 communicate with the two ends of the through hole 12, and allow both sides of the curtain plate 11 to slide embedded.

[0046] When the fireproof rolling door needs to be packed up, the motor is used to control the rotation of the spool, and at this moment, the spool winds the curtain plate 11 . At the same time, the curtain panel 11 slides along the inner wall of the ...

Embodiment 2

[0067] Embodiment 2: An installation process of a fire-proof rolling door, which is used to install the above-mentioned fire-proof rolling door, includes the following steps:

[0068] S1, separately transport the box body 1 and a pair of guide rails 2, and transport them to the designated installation location;

[0069] S2, use a crane to lift the box body 1, and install and fix the box body 1;

[0070] S3, install a pair of guide rails 2 on the lower end surfaces of both ends of the box body 1, and make the opening ends of the pair of guide rails 2 face each other;

[0071] S4, adjust the sliding sleeve 6 at the lower end of the guide rail 2, and fix the sliding sleeve 6, so that the lower end surface of the sliding sleeve 6 is pressed against the ground, so as to realize the leveling and fixing of the guide rail 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com