A carburetor structure for preventing oil cut-off in bumpy road sections

A carburetor and oil-cutting technology, applied in carburetors, machines/engines, engine components, etc., can solve problems such as engine flameout, float swinging, affecting the timeliness of fuel supply, etc., to ensure normal state and avoid flameout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

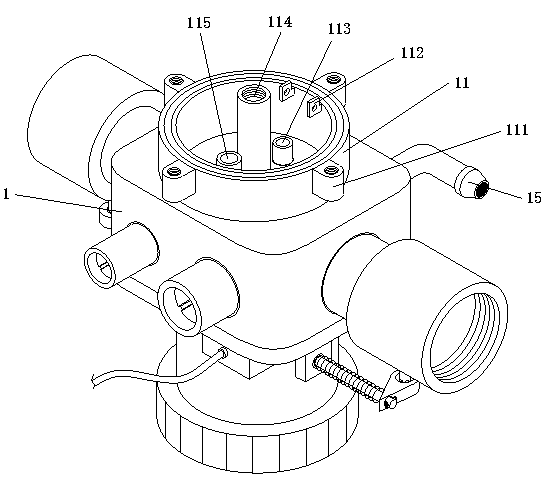

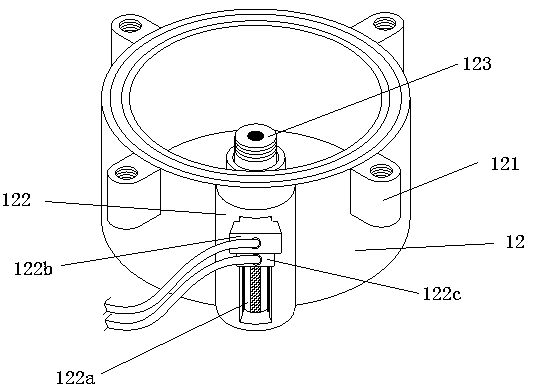

[0032] Embodiment one, please emphatically refer to the attached Figure 1-6As shown in the figure, a carburetor structure for preventing oil cut-off in a bumpy road section includes a carburetor body 1, an oil shell fixing seat 11 is arranged on one side of the carburetor body 1, and the oil shell fixing seat 11 is anastomosedly connected with an oil shell 12, a magnetic induction device 122 is vertically provided on one side of the outer wall of the oil shell 12, and a guide rail groove 122a is vertically opened on the housing of the magnetic induction device 122. An electromagnetic inductor 122b and an electromagnet locator 122c are provided, the top of the electromagnet locator 122c is connected to the bottom housing of the electromagnetic inductor 122b, and the electromagnetic inductor 122b and the electromagnet locator 122c are all in sliding connection with the guide rail groove 122a; one end of the electromagnetic inductor 122b close to the oil shell 12 is provided wit...

Embodiment 2

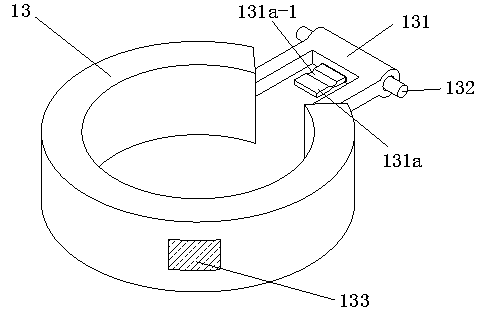

[0033] Embodiment two, please emphatically refer to the attached figure 1 , 3 As shown in and 4, the buoy 13 includes a connecting bridge 131, the two bridge seats of the connecting bridge 131 are thermally fused connected with the opening of the buoy 13, and the inside of the bridge body of the connecting bridge 131 is horizontally The central axis is penetrated with a limit pin 132, and the two ends of the limit pin 132 extend to both sides of the connecting bridge 131 and are symmetrically inserted and connected with a single-hole fixing piece 112. The two single-hole fixing pieces 112 and the two The inner wall of one side of the oil shell fixing seat 11 is connected; the outer wall of one end of the connecting bridge 131 close to the opening of the float 13 is thermally connected with a tongue piece 131a, and the upper and lower sides of the tongue piece 131a are symmetrically arranged. There is an arc-shaped groove 131a-1, and the tongue 131a is covered with a triangula...

Embodiment 3

[0034] Embodiment three, please emphatically refer to the attached figure 1 , 2 As shown in and 4, four first single-hole fixing ears 111 are equally divided on the outer wall of the oil shell fixing seat 11, and the inner center of the oil shell fixing seat 11 is provided with a main volume channel column tube 114, so One end of the main volume channel column tube 114 close to the two single-hole fixing pieces 112 is provided with an oil inlet inner column tube 113, and the end of the main volume channel column tube 114 far away from the oil inlet inner column tube 113 is provided with an auxiliary Measuring hole column tube 115; four second single-hole fixed ears 121 are equally divided on the outer wall of the end of the oil shell 12 near the opening, and the plurality of second single-hole fixed ears 121 are connected with the plurality of first single-hole fixed ears. The hole fixing ears 111 are connected one by one, and the connection method is fixed by bolts; the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com