Quick and automatic sealing pipeline joint

An automatic sealing, pipe joint technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, sleeve/socket connection, etc., can solve the problems of difficult alignment of connecting bolt holes, inconvenient installation and disassembly, affecting rescue speed, etc. , to achieve the effect of significant social and economic benefits, convenient and fast installation and disassembly, and saving valuable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

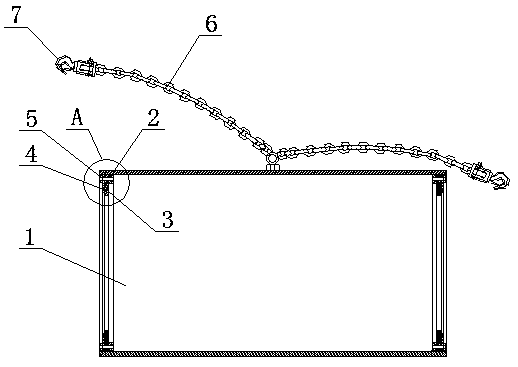

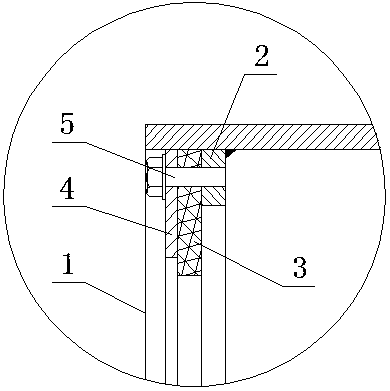

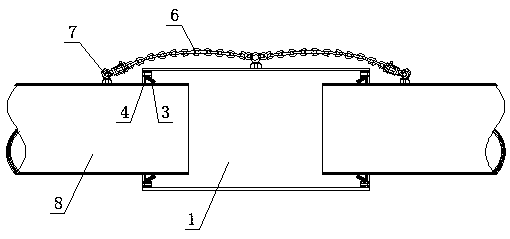

[0024] Below in conjunction with accompanying drawing, the present invention is further described as follows:

[0025] The quick self-sealing pipe joint is composed of joint body 1, fixed ring 2, sealing ring 3, compression ring 4, bolt 5, anti-off chain 6 and self-locking hook 7 (see attached Figure 1-2 ), the joint body 1 can be made into a straight cylindrical structure, an arc cylindrical structure, or a conical cylindrical structure according to the actual needs of the project. The inner wall of one end or both ends of the joint body 1 is fixed with a fixed ring 2, and at least three screw holes are evenly distributed on the fixed ring 2, and the bolt 5 is connected with the screw holes on the fixed ring 2, and the fixed ring 2 The outer surface is equipped with a sealing ring 3 and a compression ring 4 from the inside and outside through the bolt 5. The sealing ring 3 and the compression ring 4 are pressed on the outer surface of the fixed ring 2 through the bolt 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com