Axis torque sensor

A sensor and axial torque technology, applied in the field of sensors, can solve the problems of insufficient connection between the sensor and the stepping rod, no protective structure for the sensor, and inconvenient connection of the sensor, etc., so as to improve safety, improve the use effect and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

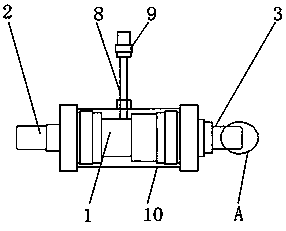

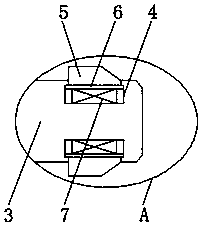

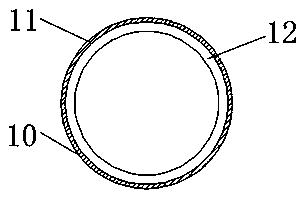

[0023] refer to Figure 1-3 , an axial torque sensor, comprising a sensor body 1 and a protective case 10, one end of the sensor body 1 is fixedly mounted with a first joint 2, the other end of the sensor body 1 is fixedly mounted with a second joint 3, and the outer surface of the second joint 3 A telescopic slot 4 is opened, and the inside of the telescopic slot 4 is movably connected with a top plate 5, and one end of the top plate 5 is located inside the telescopic slot 4, and a limit plate 6 is fixedly installed, and the inner wall of the telescopic slot 4 is fixedly connected with a spring 7, and the sensor body 1 One side of the outer surface is fixedly connected with a connection wire 8 , one end of the connection wire 8 is fixedly connected with a sensor joint 9 , and the protective case 10 is fixedly installed on the outer surface of the sensor body 1 .

[0024] Wherein, one end of the spring 7 is fixedly connected with the limiting plate 6 , the other end of the spr...

Embodiment 2

[0029] refer to Figure 1-2 , 4. An axial moment sensor, comprising a sensor body 1 and a protective case 10, one end of the sensor body 1 is fixedly installed with a first joint 2, the other end of the sensor body 1 is fixedly equipped with a second joint 3, and the second joint 3 The outer surface is provided with a telescopic groove 4, and the inside of the telescopic groove 4 is movably connected with a top plate 5, and one end of the top plate 5 is fixedly installed at a position inside the telescopic groove 4, and a limit plate 6 is fixedly installed, and the inner wall of the telescopic groove 4 is fixedly connected with a spring 7, and the sensor One side of the outer surface of the main body 1 is fixedly connected with a connection wire 8 , one end of the connection wire 8 is fixedly connected with a sensor connector 9 , and the protective case 10 is fixedly installed on the outer surface of the sensor main body 1 .

[0030] Wherein, one end of the spring 7 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com